Easy-to-flow composite mineral admixture, preparation method thereof and mortar prepared from admixture

A technology of composite minerals and admixtures, which is applied in the field of easy-flowing composite mineral admixtures and its preparation method and the mortar prepared by using the admixtures, can solve the problems of large concrete shrinkage, reduction of concrete water-binder ratio, and mineral powder requirements. Low water volume and other problems, achieve high compressive strength, improve fluidity, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

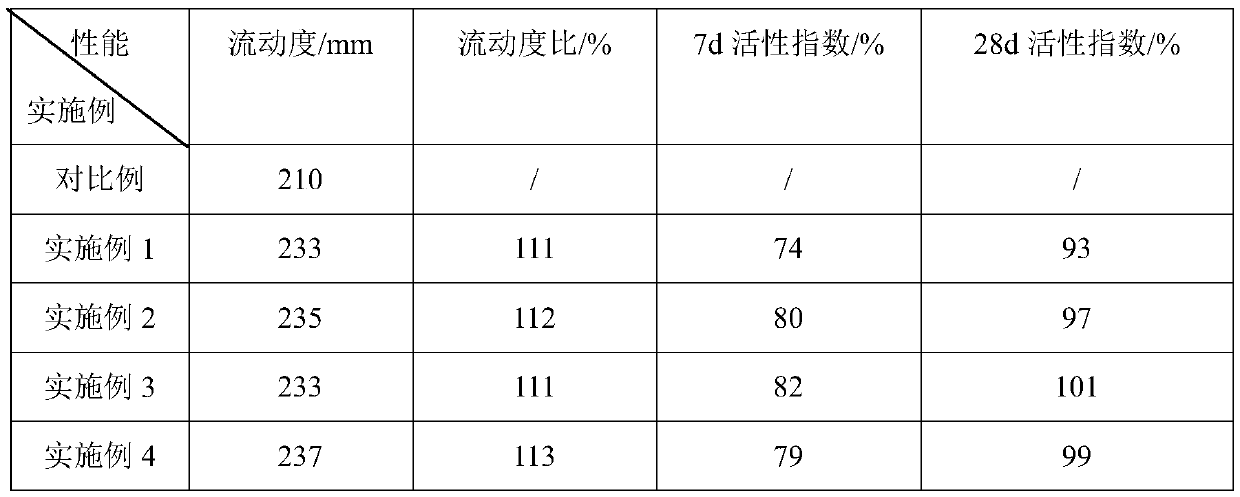

Examples

Embodiment 1

[0019] The raw materials included in the easy-flowing composite mineral admixture are shown in Table 1 below. Among them, the grinding aid is a mixture of 80 parts of silicone resin and 20 parts of sodium polyacrylate dispersant, accounting for 0.2% of the sum of mineral powder, fly ash floating beads and quartz sand tailings.

[0020] The admixture component of table 1 embodiment 1

[0021] raw material mineral powder Fly ash floating beads Quartz sand tailings Content / part 40 40 20

[0022] The preparation method of the easy-flowing composite mineral admixture comprises the steps of: putting mineral powder, quartz sand tailings and grinding aids into a ball mill, and grinding until the screening amount of a 45 μm square hole sieve is less than 12%. The raw material was dried in an oven at 105°C, and after cooling, it was mixed evenly with fly ash floating beads in a V-type mixer to obtain an easy-flowing composite mineral admixture.

[0023] The ...

Embodiment 2

[0028] The raw materials included in the easy-flowing composite mineral admixture are shown in Table 3 below. Among them, the grinding aid is a mixture of 80 parts of silicone resin and 20 parts of sodium polyacrylate dispersant, accounting for 0.3% of the sum of mineral powder, fly ash floating beads and quartz sand tailings.

[0029] The admixture component of table 3 embodiment 2

[0030] raw material mineral powder Fly ash floating beads Quartz sand tailings Content / part 60 20 20

[0031] The preparation method of the easy-flowing composite mineral admixture comprises the steps of: putting mineral powder, quartz sand tailings and grinding aids into a ball mill, and grinding until the screening amount of a 45 μm square hole sieve is less than 12%. The raw material was dried in an oven at 105°C, and after cooling, it was mixed evenly with fly ash floating beads in a V-type mixer to obtain an easy-flowing composite mineral admixture.

[0032] The ...

Embodiment 3

[0037] The raw materials included in the easy-flowing composite mineral admixture are shown in Table 5 below. Among them, the grinding aid is a mixture of 80 parts of silicone resin and 20 parts of sodium polyacrylate dispersant, accounting for 0.4% of the sum of mineral powder, fly ash floating beads and quartz sand tailings.

[0038] The admixture component of table 5 embodiment 3

[0039] raw material mineral powder Fly ash floating beads Quartz sand tailings Content / part 50 30 20

[0040] The preparation method of the easy-flowing composite mineral admixture comprises the steps of: putting mineral powder, quartz sand tailings and grinding aids into a ball mill, and grinding until the screening amount of a 45 μm square hole sieve is less than 12%. The raw material was dried in an oven at 105°C, and after cooling, it was mixed evenly with fly ash floating beads in a V-type mixer to obtain an easy-flowing composite mineral admixture.

[0041] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com