A kind of extraction method of quinoa straw vegetable protein

The technology of a vegetable protein and an extraction method, which is applied in the field of extraction of vegetable protein from quinoa straw, can solve the problems of easy denaturation, great destructiveness of sulfur-containing amino acids, environmental pollution, etc., so as to improve the content of solids and save the consumption of solvents. , the effect of scientific and reasonable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

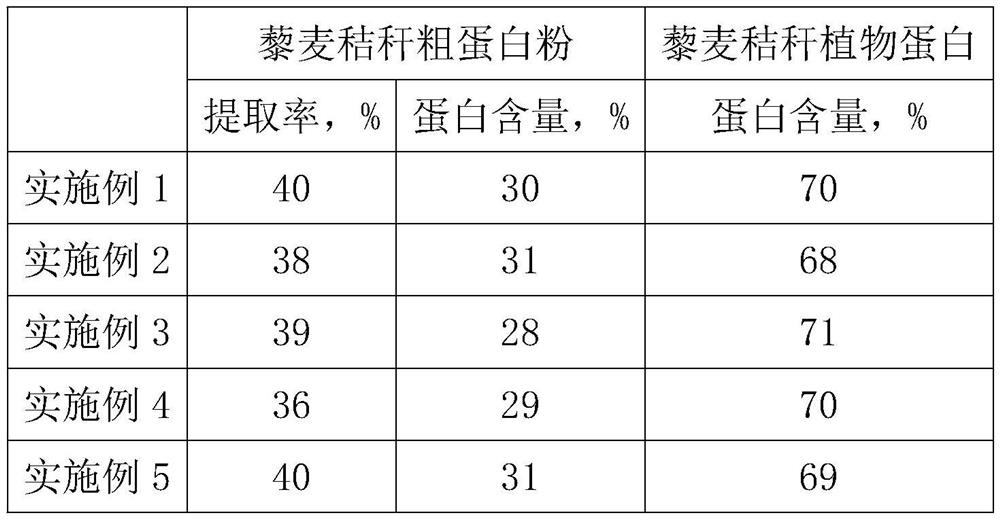

Examples

Embodiment 1

[0035] A method for extracting quinoa stalk vegetable protein, comprising the following steps:

[0036] (1) Harvesting of quinoa stalks: take fresh, moth-free quinoa stalks;

[0037] (2) Mixed liquid: mix quinoa straw with deionized water according to the mass ratio of 1:3;

[0038] (3) beating: cut the stalks into 5cm segments and place them in a beater for beating;

[0039] (4) Ultrasonic treatment: the quinoa straw after beating was ultrasonically treated at room temperature with an ultrasonic power of 350-450W and an ultrasonic time of 60 minutes to obtain a straw solution;

[0040] (5) adjust pH: add strong acid or strong alkali to adjust pH of straw solution to 3.8;

[0041] (6) Enzyme addition: Dissolve pectinase in an aqueous solution with pH 3.8 and a temperature of 50° C., and add 250 U / g to the straw solution;

[0042] (7) Enzymolysis: the enzymolysis reaction is carried out in a water bath, the temperature is 50°C, and the enzymolysis treatment is 8 hours;

[0...

Embodiment 2

[0049] A method for extracting quinoa stalk vegetable protein, comprising the following steps:

[0050] (1) Harvesting of quinoa stalks: take fresh, moth-free quinoa stalks;

[0051] (2) Mixed liquid: mix quinoa straw with deionized water according to the mass ratio of 1:3;

[0052] (3) beating: cut the stalks into 5cm segments and place them in a beater for beating;

[0053] (4) Ultrasonic treatment: the quinoa straw after beating was ultrasonically treated at room temperature with an ultrasonic power of 350-450W and an ultrasonic time of 60 minutes to obtain a straw solution;

[0054] (5) adjust pH: add strong acid or strong alkali to adjust pH of straw solution to 4.8;

[0055] (6) Enzyme addition: dissolve cellulase in an aqueous solution with a pH of 4.8 and a temperature of 50° C., and add 250 U / g to the straw solution;

[0056] (7) Enzymolysis: the enzymolysis reaction is carried out in a water bath, the temperature is 50°C, and the enzymolysis treatment is 8 hours; ...

Embodiment 3

[0063]A method for extracting quinoa stalk vegetable protein, comprising the following steps:

[0064] (1) Harvesting of quinoa stalks: take fresh, moth-free quinoa stalks;

[0065] (2) Mixed liquid: mix quinoa straw with deionized water according to the mass ratio of 1:3;

[0066] (3) beating: cut the stalks into 5cm segments and place them in a beater for beating;

[0067] (4) Ultrasonic treatment: the quinoa straw after beating was ultrasonically treated at room temperature with an ultrasonic power of 350-450W and an ultrasonic time of 60 minutes to obtain a straw solution;

[0068] (5) adjust pH: add strong acid or strong alkali to adjust pH of straw solution to 4.5;

[0069] (6) Enzyme addition: dissolve glucoamylase in an aqueous solution with pH 4.5 and temperature 45°C, and add 250U / g to the straw solution;

[0070] (7) Enzymolysis: the enzymolysis reaction was carried out in a water bath at a temperature of 45°C, and the enzymolysis treatment was carried out for 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com