Quick-positioning two-component acrylate structural adhesive and preparation method and use method thereof

A technology of structural adhesives and acrylates, applied in the directions of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of shortening the room temperature operation time and increasing the difficulty of operation, and achieves a large adjustable range and comprehensive Excellent performance, fast positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

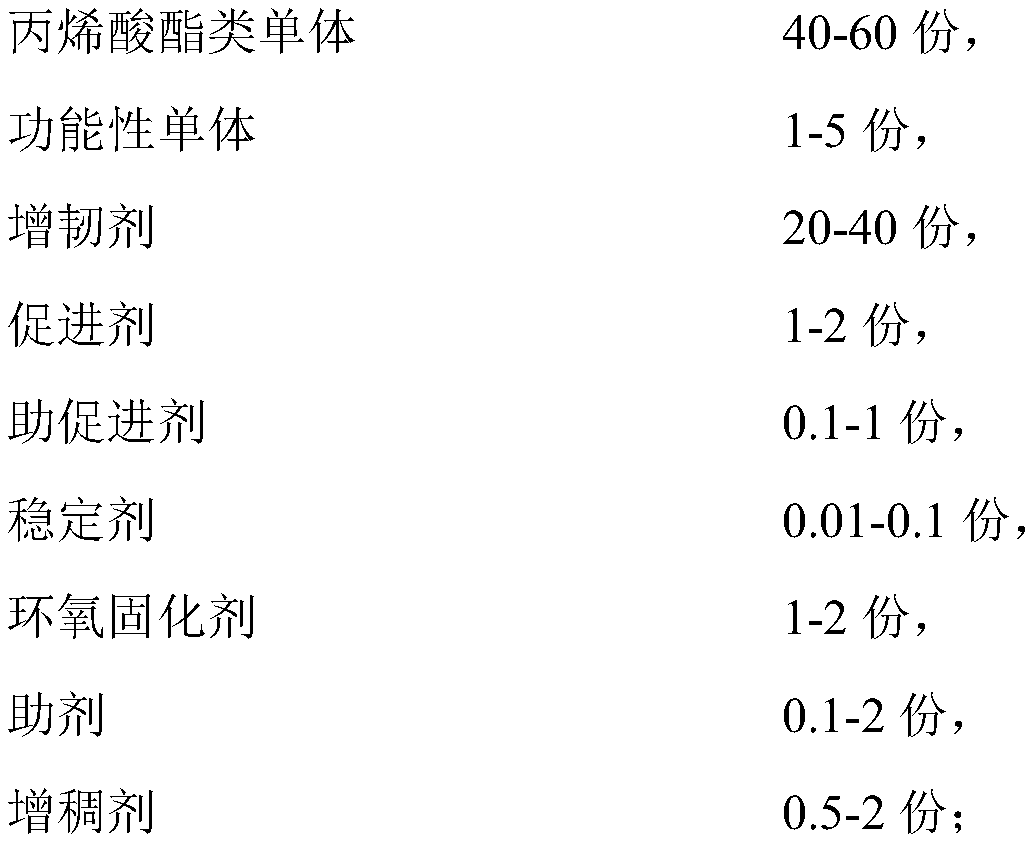

[0031] A component

[0032]

[0033]

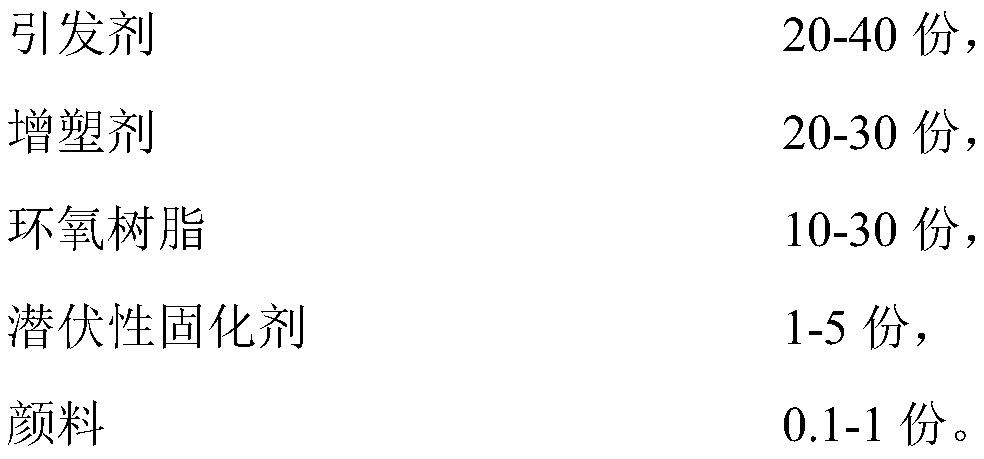

[0034] B component

[0035] component name Component amount Diethylene glycol dibenzoate 30 Benzoyl peroxide 32 Bisphenol A epoxy resin 30 Modified amine latent curing agent 5 pigment 3

[0036] Preparation Process:

[0037] Preparation of component A: Accurately weigh methyl methacrylate, hydroxyethyl methacrylate, tetrahydrofuran acrylate, methacrylic acid, hydroquinone, EDTA-Na, mix well; then add ABS resin, hydrogenated nitrile rubber , stir to dissolve completely; add polyurethane modified acrylic resin, N,N-dimethyl-p-toluidine, zinc diethyldithiocarbamate, PM-2, mercaptan curing agent, stir evenly, and finally add gas phase Stir the white carbon black evenly, hold the vacuum for degassing, and discharge the material to obtain component A.

[0038] Preparation of component B: Accurately weigh diethylene glycol dibenzoate, benzoyl peroxide, and bisphenol A epoxy resin, stir well t...

Embodiment 2

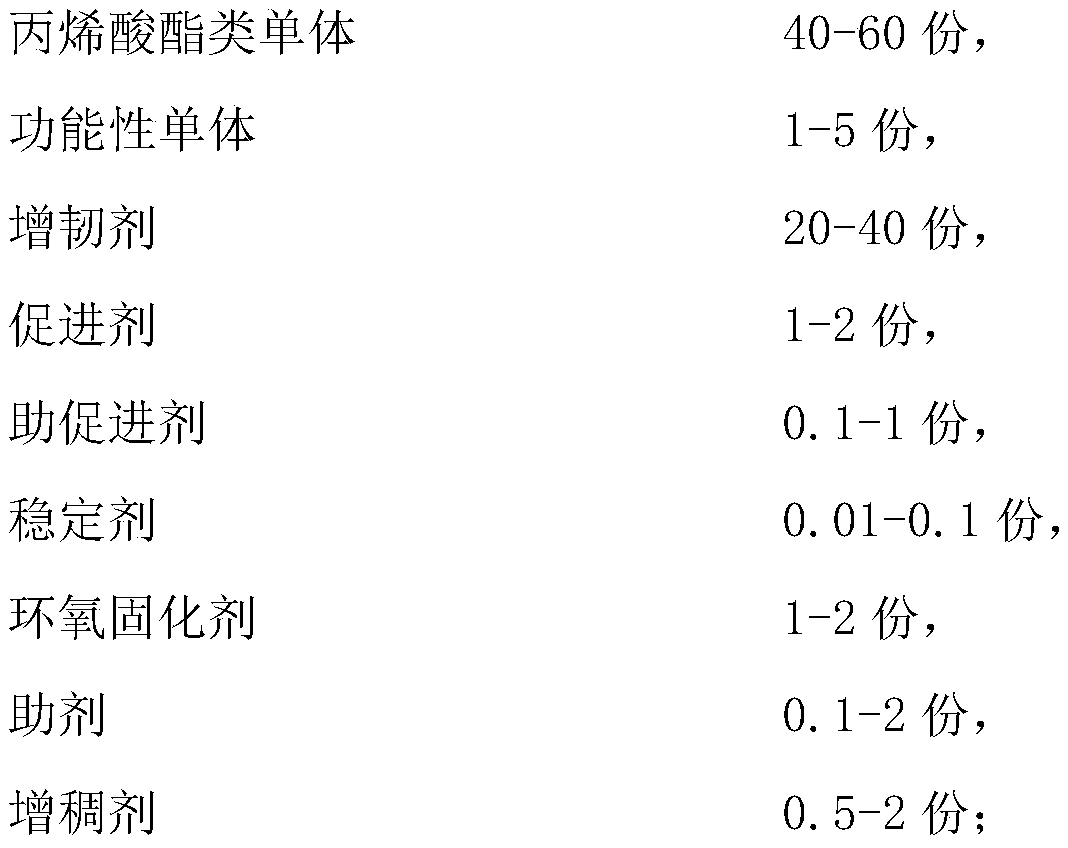

[0041] A component

[0042]

[0043]

[0044] B component

[0045] component name Component amount Dioctyl adipate 30 Benzoyl peroxide 32 Bisphenol F epoxy resin 30 Modified amine latent curing agent 5 pigment 3

[0046] Preparation Process:

[0047] Preparation of component A: Accurately weigh methyl methacrylate, hydroxypropyl methacrylate, tetrahydrofuran acrylate, methacrylic acid, 2-tert-butylhydroquinone, EDTA-Na and mix evenly; then add MBS resin, Polyacrylate rubber, stir to dissolve completely; add epoxy-modified acrylic resin, N,N-dihydroxyethyl-p-toluidine, triphenylphosphine, PM-2010SP, mercaptan, stir evenly, and finally add fume white Stir the carbon black evenly, hold the vacuum for degassing, and discharge to obtain component A.

[0048] Preparation of component B: Accurately weigh dioctyl adipate, benzoyl peroxide, and bisphenol F epoxy resin, stir thoroughly to dissolve them completely, add modified amine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com