Multistage chiral luminescence enhanced composite material and preparation method thereof

A composite material, luminescence enhancement technology, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of low quantum efficiency, difficult to generate chiral structure, etc., and achieve low preparation cost , easy to operate, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A composite material with multilevel chiral luminescence enhancement (AgNR@SiO 2 @L-cys @CsPbBr 3 ) of the preparation process is as follows, specifically divided into five steps:

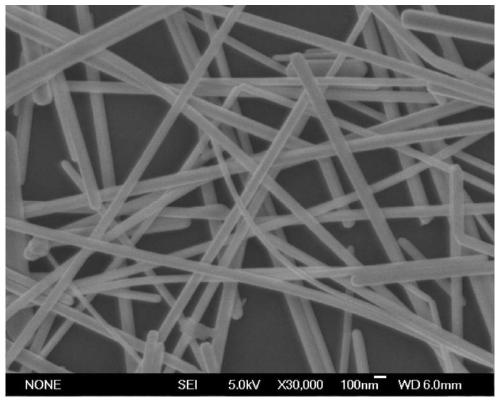

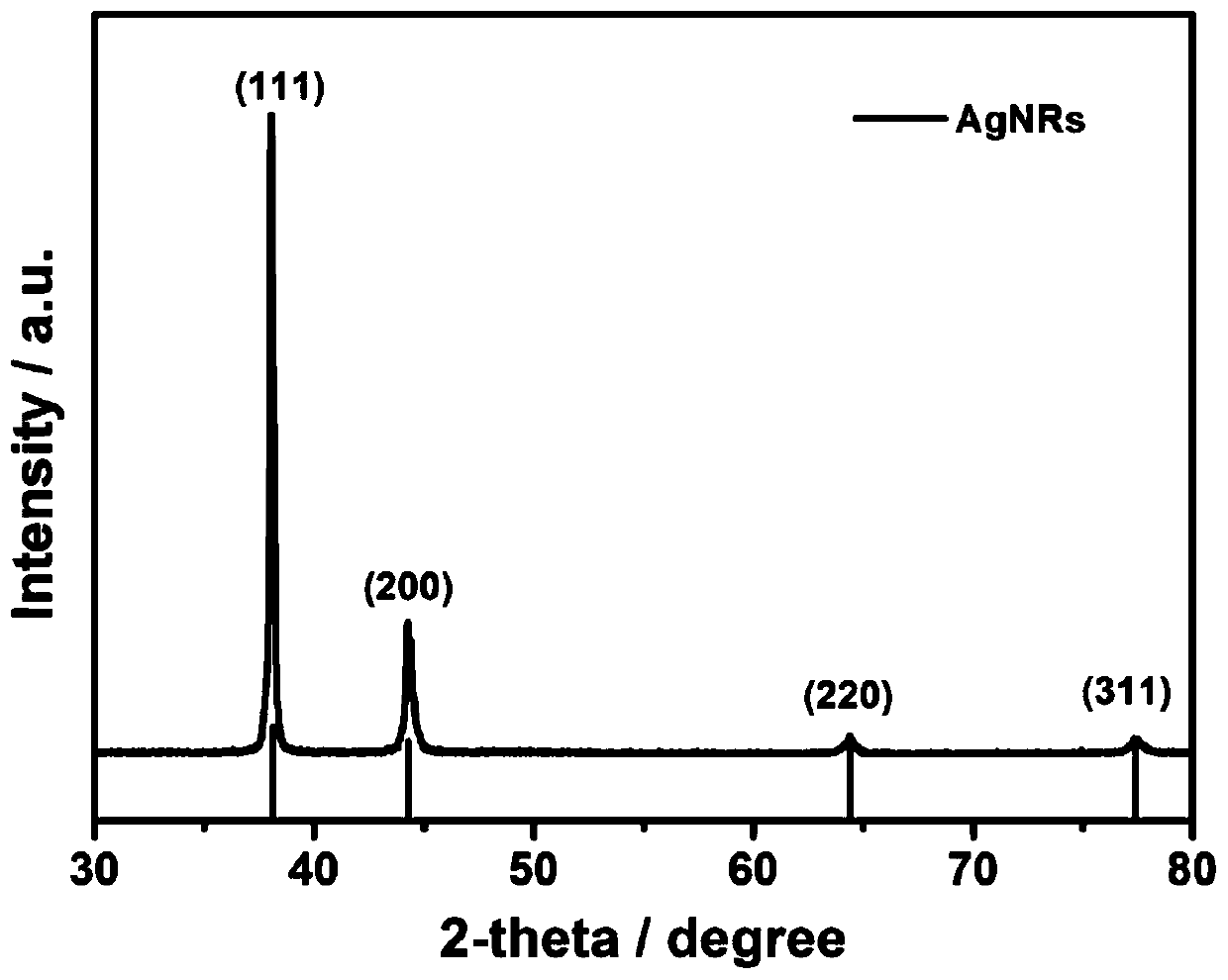

[0035] 1. Synthesis of silver nanorods (AgNRs) aqueous solution:

[0036] Add 0.2 g of PVP to 25 mL of ethylene glycol, stir and dissolve, add 0.25 g of silver nitrate, add 3.75 g (concentration: 600 mmol / L) of ethylene glycol solution of ferric chloride after dissolving, stir well and transfer to oil In a bath, stir at 130°C for 5 hours. The crude product was then washed by centrifugation and finally dispersed in 10 mL of deionized water.

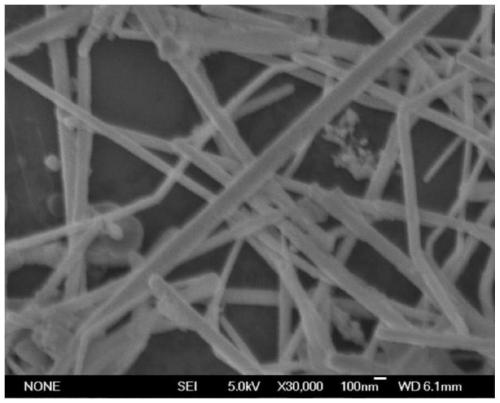

[0037] 2. AgNR@SiO with multi-level nanostructure 2 Synthesis of composite materials:

[0038] Add 2 mL of the silver nanorod aqueous solution prepared in step 1 into 20 mL of isopropanol, then add 20 microliters of TEOS and 10 microliters of APTES, stir well and then add 1.9 mL of ammonia solution. The solution was stirred at room temperature for ...

Embodiment 2

[0048] A composite material with multilevel chiral luminescence enhancement (AgNR@SiO 2 @L-cys @CsPbCl 3 ) of the preparation process is as follows, specifically divided into five steps:

[0049] 1. Synthesis of silver nanorods (AgNRs) aqueous solution:

[0050] Add 0.2 g of PVP to 25 mL of ethylene glycol, stir and dissolve, add 0.25 g of silver nitrate, add 3.75 g (concentration: 600 mmol / L) of ethylene glycol solution of ferric chloride after dissolving, stir well and transfer to oil In a bath, stir at 130°C for 5 hours. The crude product was then washed by centrifugation and finally dispersed in 10 mL of deionized water.

[0051] 2. AgNR@SiO with multi-level nanostructure 2 Synthesis of composite materials:

[0052] Add 2 mL of the silver nanorod aqueous solution prepared in Step 1 to 20 mL of isopropanol, then add 20 μl of TEOS and 10 μl of APTES, and then add 1.9 mL of ammonia solution. The solution was stirred at room temperature for 2 h. The crude product was th...

Embodiment 3

[0061] A composite material with multilevel chiral luminescence enhancement (AgNR@SiO 2 @L-cys @CsPbCl x Br 3-x ) of the preparation process is as follows, specifically divided into five steps:

[0062] 1. Synthesis of silver nanorods (AgNRs) aqueous solution:

[0063] Add 0.2 g of PVP to 25 mL of ethylene glycol, stir and dissolve, add 0.25 g of silver nitrate, add 3.75 g (concentration: 600 mmol / L) of ethylene glycol solution of ferric chloride after dissolving, stir well and transfer to oil In a bath, stir at 130°C for 5 hours. The crude product was then washed by centrifugation and finally dispersed in 10 mL of deionized water.

[0064] 2. AgNR@SiO with multi-level nanostructure 2 Synthesis of composite materials:

[0065] Add 2 mL of the silver nanorod aqueous solution prepared in Step 1 to 20 mL of isopropanol, then add 20 μl of TEOS and 10 μl of APTES, and then add 1.9 mL of ammonia solution. The solution was stirred at room temperature for 2 h. The crude produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com