Production process of high-activity small peptide chelated magnesium

A technology of small peptide chelation and production process, applied in the fields of peptide preparation, peptide, organic chemistry, etc., can solve the problems of low absorption and utilization rate, and achieve the effects of high production efficiency, low cost and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

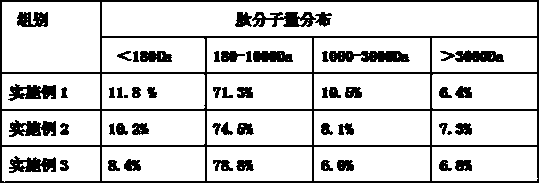

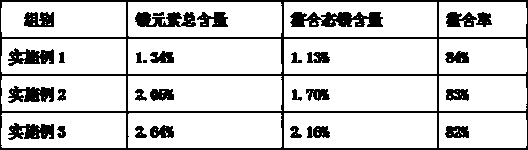

Embodiment 1

[0022] (1) Blood cell solution preparation: collect 1000L of fresh pig blood that has been anticoagulated, and use a tubular centrifuge to continuously centrifuge to obtain 455L of blood cell solution and 545L of plasma solution, collect the blood cell solution, and spray dry the plasma solution to make plasma protein powder;

[0023] (2) Hemolysis: pump the blood cell solution into the reaction tank, add 450L of deionized water, and stir continuously for 60 minutes to break the blood cells. The stirring speed is 30r / min to prepare 900L of hemolysis;

[0024] (3) Enzymolysis: Heating the hemolyzate to 50°C with continuous stirring, adjusting the pH value to 8.5 with NaOH solution, then adding protease at 1.2% of the weight of the blood cell solution, stirring continuously, and detecting the enzymolysis solution at intervals of one hour pH value, when the pH value drops below 8.5, adjust the pH value to 8.5 with alkali supplementation solution, heat the enzymolysis solution for ...

Embodiment 2

[0030] (1) Preparation of blood cells: collect 1000L of fresh pig blood that has been anticoagulated, and use a tubular centrifuge to continuously centrifuge to obtain 430L of blood cells and 570L of plasma, collect the blood cells, and spray dry the plasma to make plasma protein powder;

[0031] (2) Hemolysis: pump the blood cell solution into the reaction tank, add 430L of deionized water, and stir continuously for 60 minutes to break the blood cells. The stirring speed is 30r / min to prepare 850L of hemolysis;

[0032] (3) Enzymolysis: Heat the hemolyzate to 55°C with continuous stirring, adjust its pH value to 8.2 with NaOH solution, then add protease at 2% of the weight of the blood cell solution, keep stirring, and check the enzymolysis solution at intervals of one hour PH value, when the pH value drops below 8.2, adjust the pH value to 8.2 with alkali supplementation solution, keep the enzymatic hydrolysis for 4 hours, heat the enzymatic hydrolysis solution to 85°C to ina...

Embodiment 3

[0038] (1) Preparation of blood cells: collect 1000L of fresh pig blood that has been anticoagulated, and use a tubular centrifuge to continuously centrifuge to obtain 410L of blood cells and 590L of plasma, collect the blood cells, and spray-dry the plasma to make plasma protein powder;

[0039] (2) Hemolysis: pump the blood cell solution into the reaction tank, add 400L of deionized water, and stir continuously for 60 minutes to break the blood cells. The stirring speed is 30r / min to prepare 800L of hemolysis;

[0040] (3) Enzymolysis: Heating the hemolyzate to 52°C with continuous stirring, adjusting the pH value to 8.0 with NaOH solution, then adding 1.5% protease by weight of the blood cell solution, stirring constantly, and detecting the enzymatic hydrolyzate at intervals of one hour pH value, when the pH value drops below 8.0, adjust the pH value to 8.0 with alkali supplementation solution, heat the enzymolysis solution for 5 hours, heat the enzymolysis solution to 85°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com