A kind of automobile door sill beam aluminum alloy and preparation method thereof

A technology of threshold beam and aluminum alloy is applied in the field of automobile threshold beam aluminum alloy and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

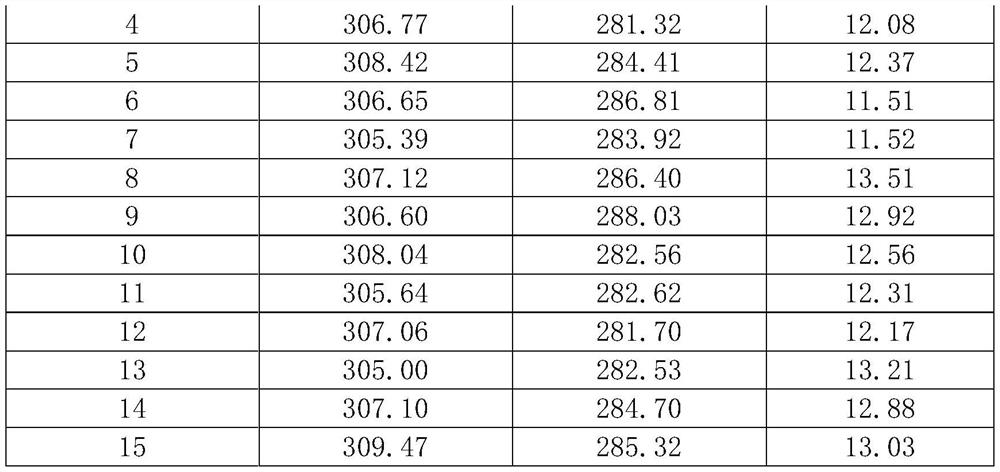

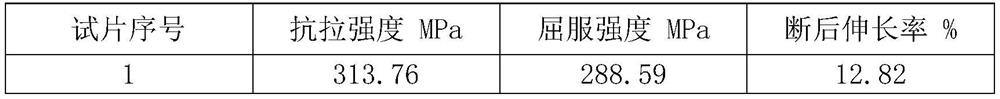

[0026] Example 1 Preparation of aluminum alloy for automobile door sill beam and its performance verification

[0027] Implementing equipment: 25T aluminum smelting furnace and its casting system, 40T homogenizing furnace, aluminum rod sawing machine, aluminum extrusion machine-2200T, aging electric furnace, milling machine, 20T universal testing machine.

[0028] Preparation steps:

[0029] (1) Smelting aluminum liquid, adding aluminum-copper alloy with copper content of 50wt%, aluminum-silicon alloy with silicon content of 20wt%, magnesium ingot of 99.9wt%, manganese agent with manganese content of 75wt%, during the smelting process, the temperature of aluminum liquid is 740 -760°C; in the final aluminum rod, the alloy content in mass percentage meets: magnesium 0.90-1.10wt%, silicon 0.90-1.10%, manganese 0.50-0.80%, copper 0.20-0.40%;

[0030] (2) The aluminum liquid adopts two-stage filtration, and the mesh numbers of the filter plates are 40 mesh and 60 mesh respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com