Fluorescent module and laser lighting system

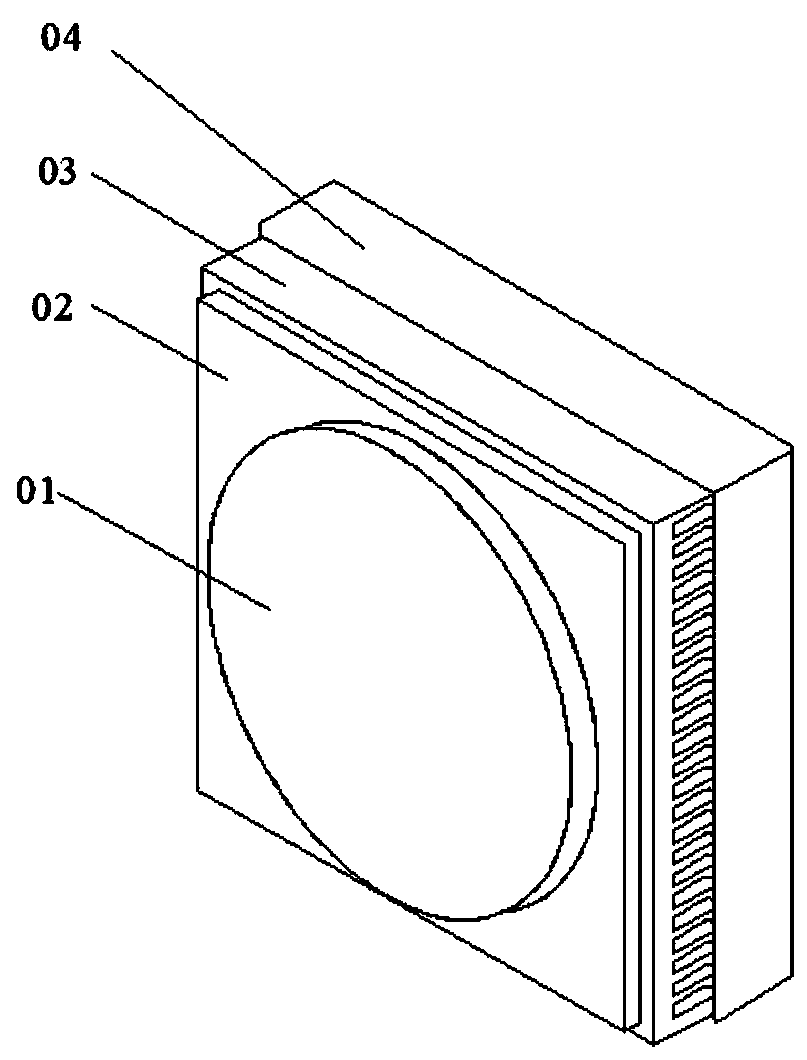

A fluorescent and modular technology, applied in the field of laser lighting, can solve the problems of difficult control of phosphor uniformity, spot heat conduction process, and uneven wavelength conversion, and achieve uniform color and intensity, high thermal conductivity, and uniform conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Select YAG:Ce with a size of 8×8mm 3+ Fluorescent crystal, apply 0.75v, 3A power supply, use a laser diode with a laser light source of 455nm to irradiate YAG:Ce 3+ fluorescent crystals. When the fluorescence is saturated, the laser power is 6W and the luminous flux is 300lm.

[0042] Then choose YAG:Ce with a size of 8×8mm 3+ Fluorescent crystal, 10×10mm semiconductor refrigeration device (TEC), and 15×15mm aluminum heat sink are connected and fixed by thermal conductive silica gel, 0.75v, 3A power supply is applied, and the laser is a 455nm laser diode. A fluorescent module using a TEC and a heat sink converts YAG:Ce 3+ When the fluorescence of the fluorescent ceramic is saturated, the laser power is increased from 6W to 10W, and the luminous flux is increased from 300lm to 500lm. At the same time, the emitted light has no light spots, which shows that it greatly improves the fluorescence saturation threshold.

Embodiment 2

[0044] Use LuAG:Ce with a size of 5×5mm 3+ Fluorescent glass, apply 3V, 3A power supply, use a laser diode with a laser light source of 450nm to irradiate LuAG:Ce 3+ For fluorescent glass, when its fluorescence is saturated, the laser power is 1W and the luminous flux is 200lm.

[0045]Then choose LuAG:Ce with a size of 5×5mm 3+ Fluorescent glass, 15×15mm TEC, and 20×20mm copper radiator are connected by thermal conductive silica gel and fixed with high temperature thermal conductive glue. 3v, 3A power supply is applied, and the laser is a 450nm laser diode. LuAG:Ce 3+ When the fluorescence of the fluorescent glass is saturated, the laser power is increased from 1W to 2.5W, and the luminous flux is increased from 200lm to 400lm, which greatly improves the fluorescence saturation threshold, and the emitted light has no spots.

Embodiment 3

[0047] Choose YAG:Ce with a size of 3×3mm 3+ Fluorescent ceramics, apply 0.75V, 3A power supply, and irradiate YAG:Ce with a laser diode with a laser light source of 460nm 3+ For fluorescent ceramics, when the fluorescence is saturated, the laser power is 5W and the luminous flux is 400lm.

[0048] Then choose YAG:Ce with a size of 3×3mm 3+ Fluorescent ceramic, 10×10mm TEC and 15×15mm copper radiator, the fluorescent ceramic and TEC are connected by brazing, the TEC and the radiator are connected by thermally conductive silica gel and fixed with high-temperature thermally conductive glue, apply 0.75v, 3A power supply, The fan is connected to the heat sink, and the laser is a 460nm laser diode. Through this mod, YAG:Ce 3+ When the fluorescence of the fluorescent glass is saturated, the laser power is increased from 5W to 15W, and the luminous flux is increased from 400lm to 1000lm, which greatly improves the fluorescence saturation threshold, and the emitted light has no spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com