A kind of pressure sensor and its manufacturing method

A pressure sensor and pressure technology, applied in instruments, measuring force, measuring devices, etc., can solve the problems of poor sensor temperature characteristics, large chip size, complex process, etc., to ensure controllability and uniformity, reduce chip size, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

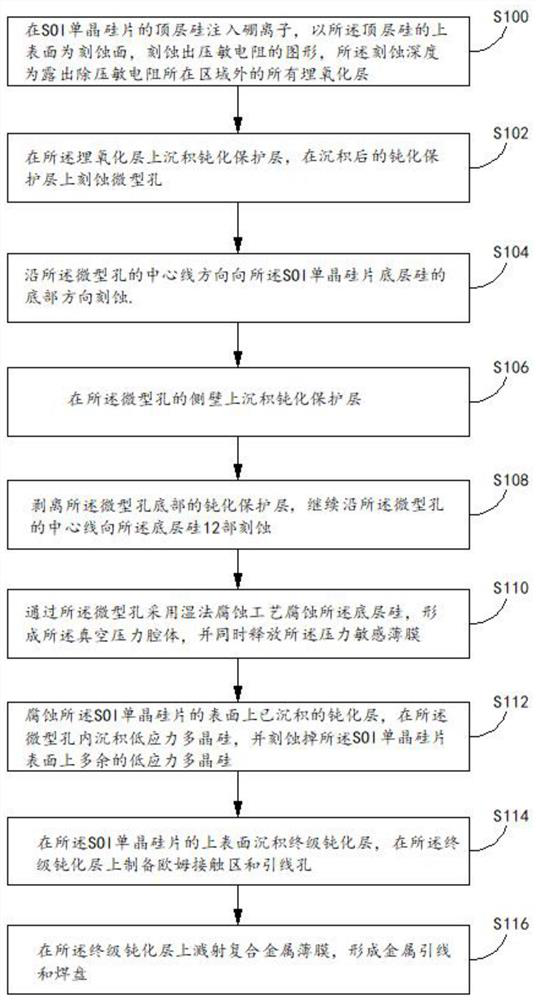

Method used

Image

Examples

Embodiment Construction

[0035] The substantive features and remarkable progress of the present invention will be further described below through specific implementation, but the present invention is by no means limited to the described embodiments.

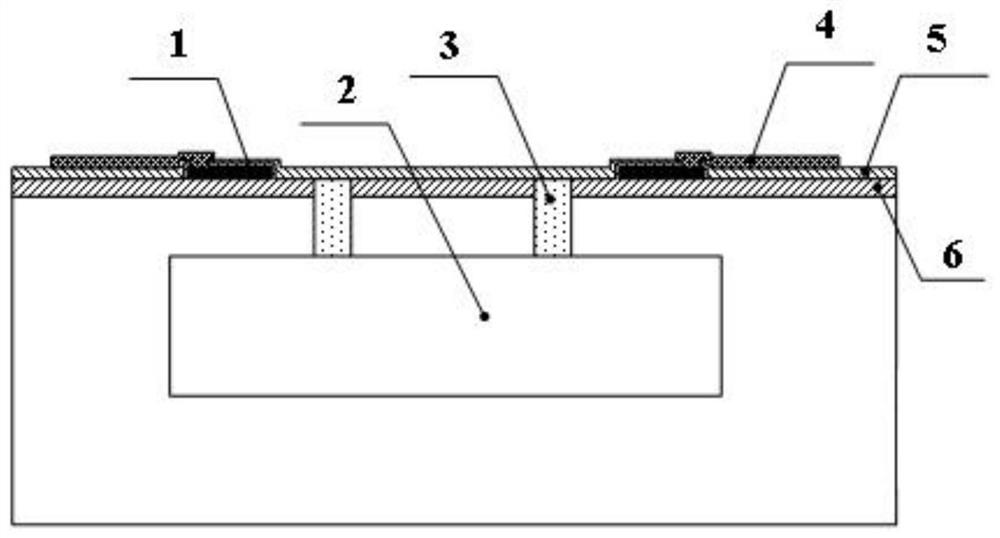

[0036] Specifically, this embodiment discloses a pressure sensor. The pressure sensor includes an SOI single crystal silicon wafer. Preferably, the SOI single crystal silicon wafer is N-type single throw or double throw (111) SOI single crystal silicon There are 8 (111) crystal planes in the (111) SOI monocrystalline silicon wafer, which are respectively the upper and lower surfaces of the silicon wafer and the angles between the upper and lower surfaces of the silicon wafer and the two sides of each other. Composition of 6 (111) crystal planes interlaced.

[0037] The SOI single crystal silicon wafer includes a buried oxide layer 6, and the buried oxide layer 6 separates the SOI single crystal silicon wafer into a top layer of silicon 7 located above th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com