Lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of lithium-ion battery electrochemical performance, MOF materials are easy to agglomerate, etc., to achieve Reduce adverse effects, not easy to agglomerate, and adapt to volume changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0033] The lithium ion battery negative electrode material provided by the invention is prepared by the following method:

[0034] Step 1: Pretreatment of carbon cloth

[0035] Cut the carbon cloth into a circle with a radius of 0.8 cm, put it into acetone, alcohol, and deionized water in turn, ultrasonically clean it for 30 minutes, and put it in an oven at 80°C for drying.

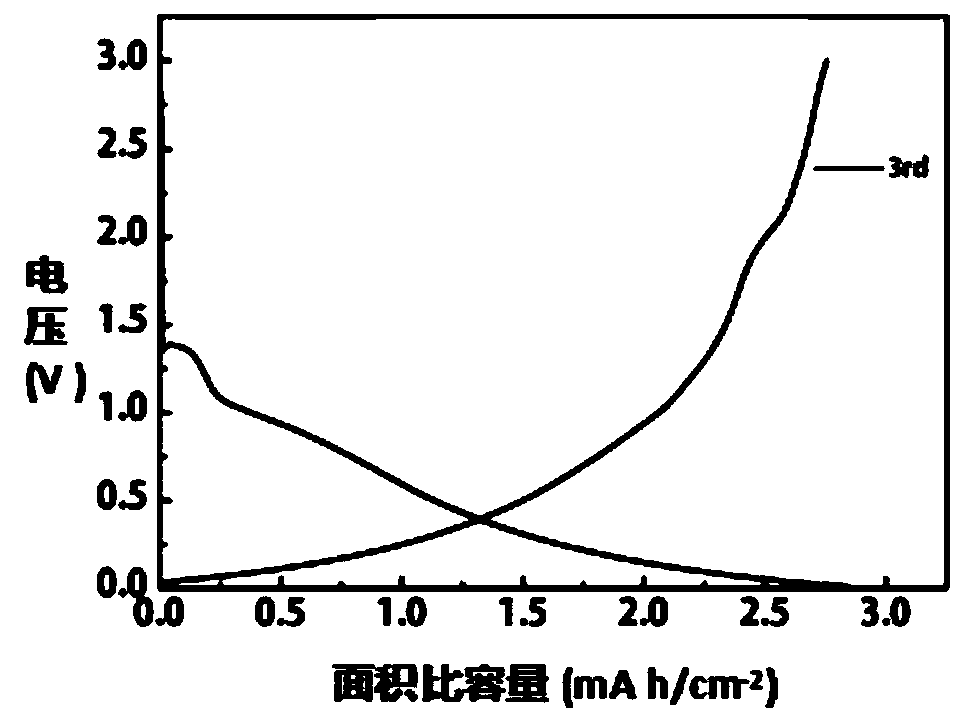

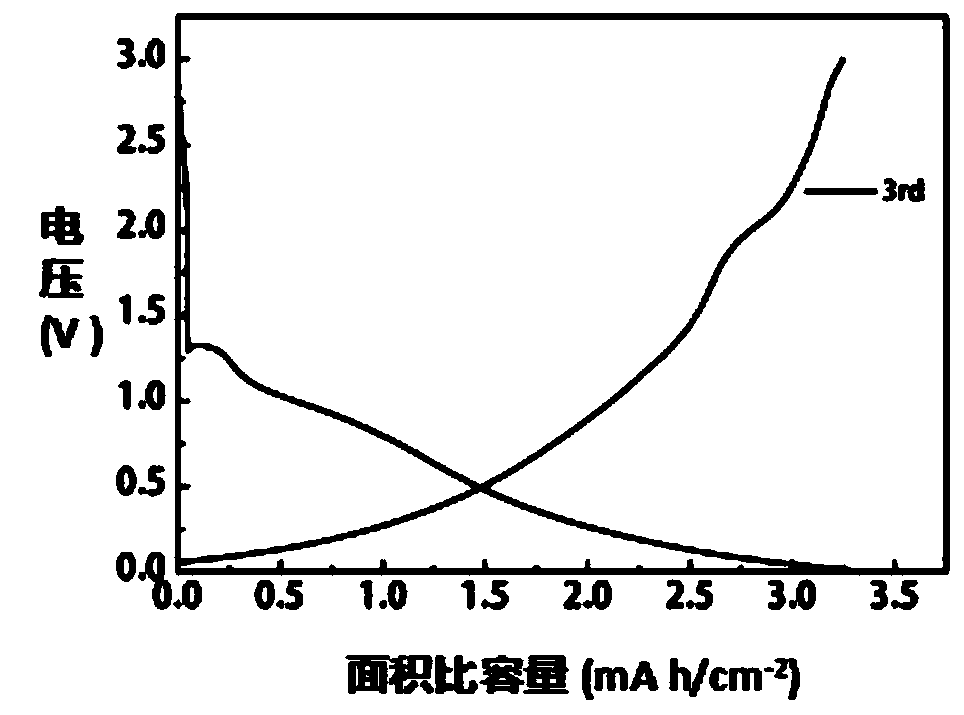

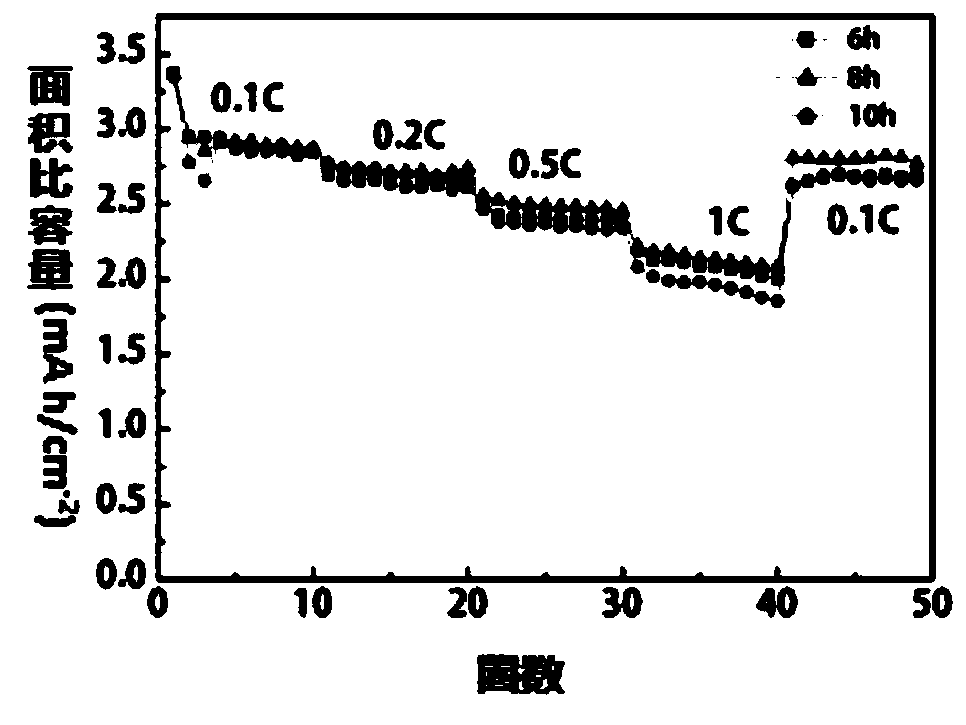

[0036] Step 2: Synthesis of Co(CO 3 ) 0.5 (OH) 0.11 h 2 o

[0037] Add 2mmol Co(No 3 ) 2 ·6H 2 0, 5mmol urea, 5mmol NH 4 F was mixed with 35 mL of deionized water and stirred at room temperature for 20 min to obtain a hydrothermal solution. Move the above-mentioned hydrothermal solution into the liner of the hydrothermal kettle and put the above-mentioned pretreated carbon cloth. The hydrothermal condition is 100°C for 6-10h (6h, 8h, 10h). After the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com