Light-operated semiconductor switch

A semiconductor and switch technology, applied in the field of light-controlled semiconductor switches, can solve the problems of photoconductive switch dependence, inability to adapt to miniaturization requirements, slow turn-on speed, etc., to improve anti-electromagnetic interference ability, increase current conduction uniformity, reduce The effect of small delay jitter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

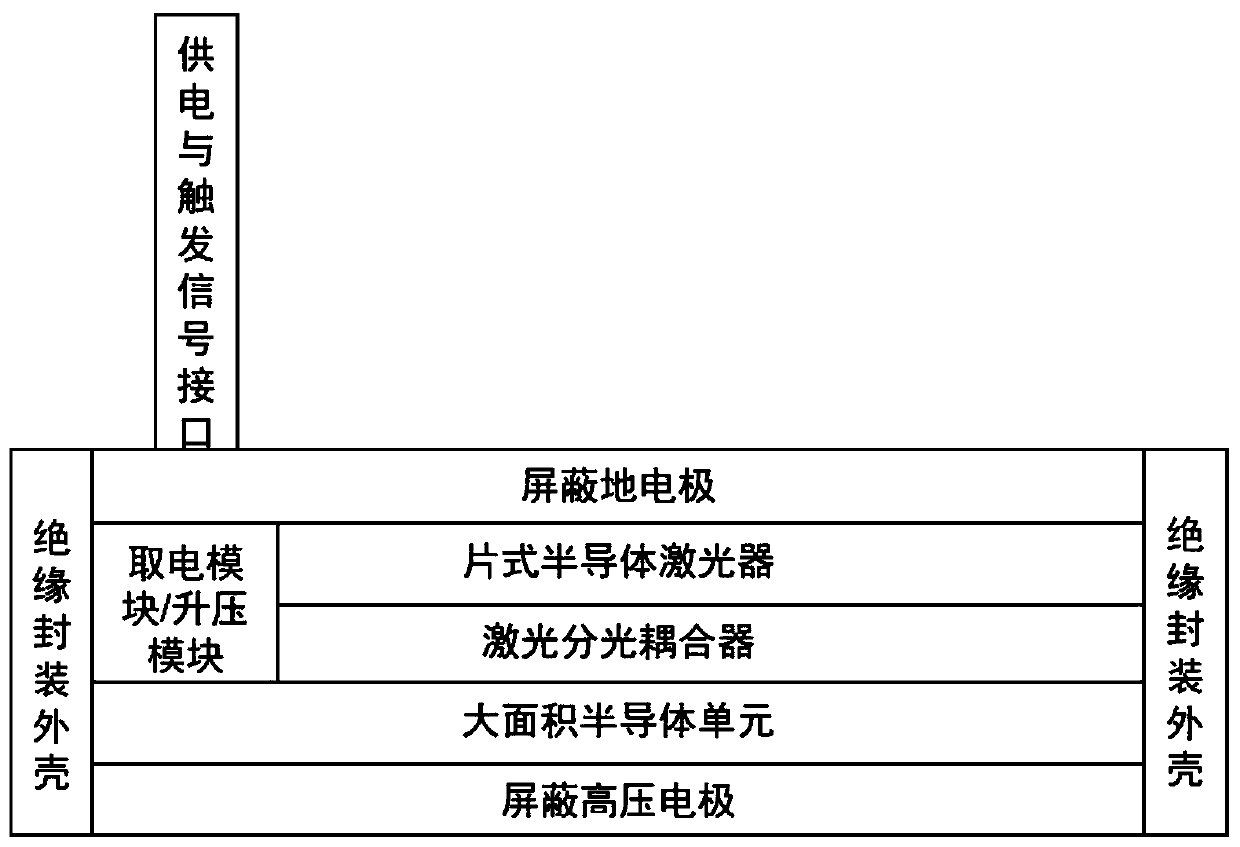

[0055] Apply a high voltage between the shielding ground electrode and the shielding high voltage electrode, the voltage range of the high voltage is 1kV ~ 12kV; the working current range is: 0 ~ 50kA; on this basis, the voltage range can be increased by series connection. Use parallel connection or increase the chip area to increase the working current range.

[0056] In the light-controlled semiconductor switch, the shielding high-voltage electrode is applied to a positive high-voltage point, and the shielding ground electrode is applied to a point or a floating low potential. There is no conduction between them, they can withstand high forward voltage and withstand high reverse voltage.

[0057]When the voltage is applied to the power supply of the optically controlled semiconductor switch and the pulse waveform is given by the trigger signal interface, the chip semiconductor laser will start to work at this time, and the high-current laser drive module in the chip semicond...

Embodiment approach

[0060] After the power supply and trigger signal are introduced into the chip semiconductor laser, a preferred implementation mode: the circuit substrate places most of the components of the high-current laser drive module on the top layer, and places most of the components of the semiconductor laser unit on the bottom layer.

[0061] The high-current laser drive module preferably uses MCT, IGBT or power MOSFET as the discharge switch, and the solid capacitor as the energy storage element. The pulse current is generally between 5A and 500A, and the output is positive pulse or negative pulse. The energy required by the current can be obtained in two ways: high-voltage power extraction and low-voltage boost.

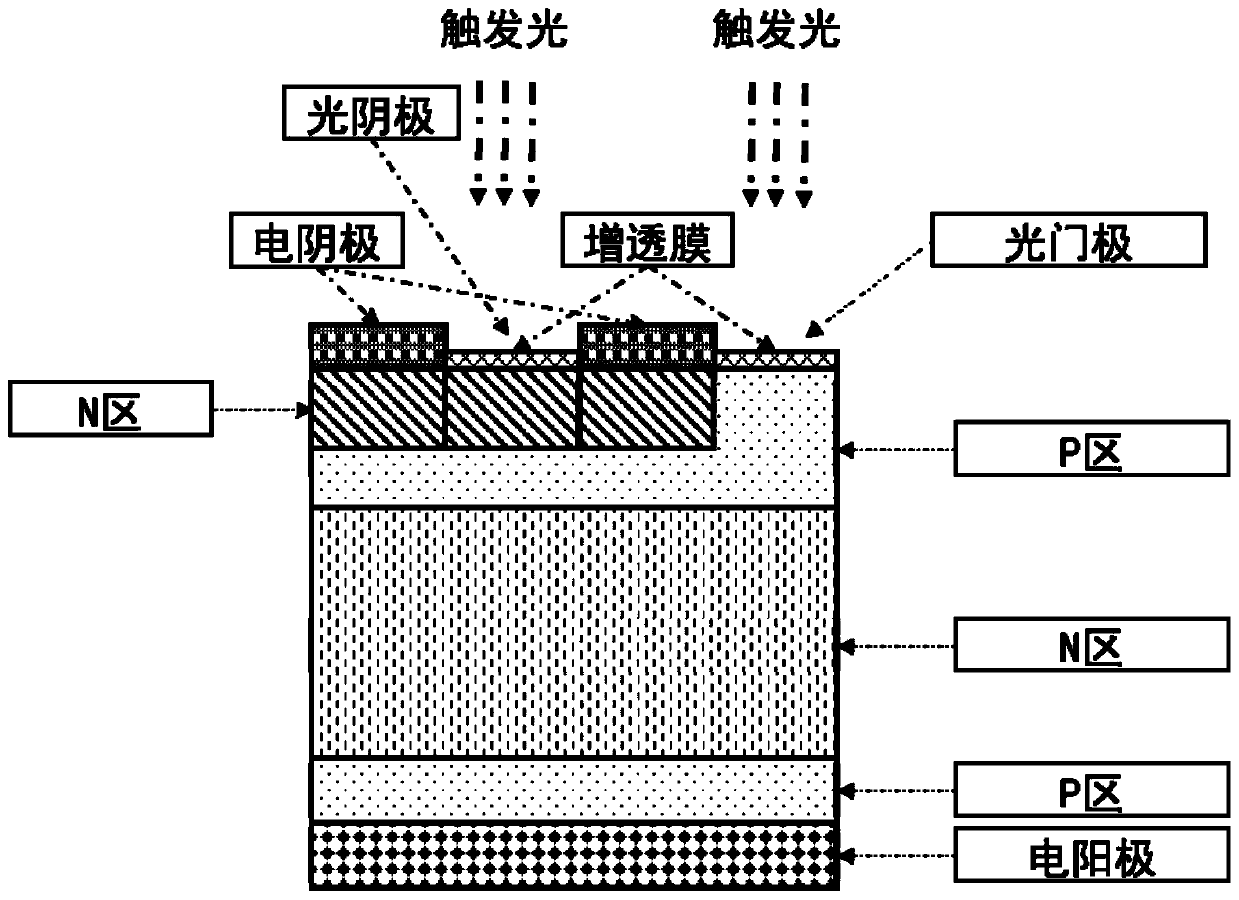

[0062] The laser diode chips are evenly distributed on the circuit substrate according to the requirements, and connected in series, parallel or series-parallel combination, and the positive and negative electrodes are drawn out. The positive and negative electrodes are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com