AC/g-C3N4 composite photocatalytic material and preparation method thereof

A composite photocatalysis, g-c3n4 technology, applied in the field of photocatalytic materials, can solve the problem of lack of chromium wastewater treatment, and achieve the effects of improving photoelectrochemical performance, good application prospects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] According to a preferred embodiment, AC / g-C of the present invention 3 N 4 The preparation method of composite photocatalytic material comprises the following steps:

[0044] Put the dicyandiamide into the muffle furnace for calcination, wherein the calcination temperature is 550°C, after the temperature of the muffle furnace rises to the calcination temperature at a heating rate of 5°C / min, keep it warm for 3 hours, then cool naturally, and the obtained solid substance Grinding to obtain g-C 3 N 4 powder.

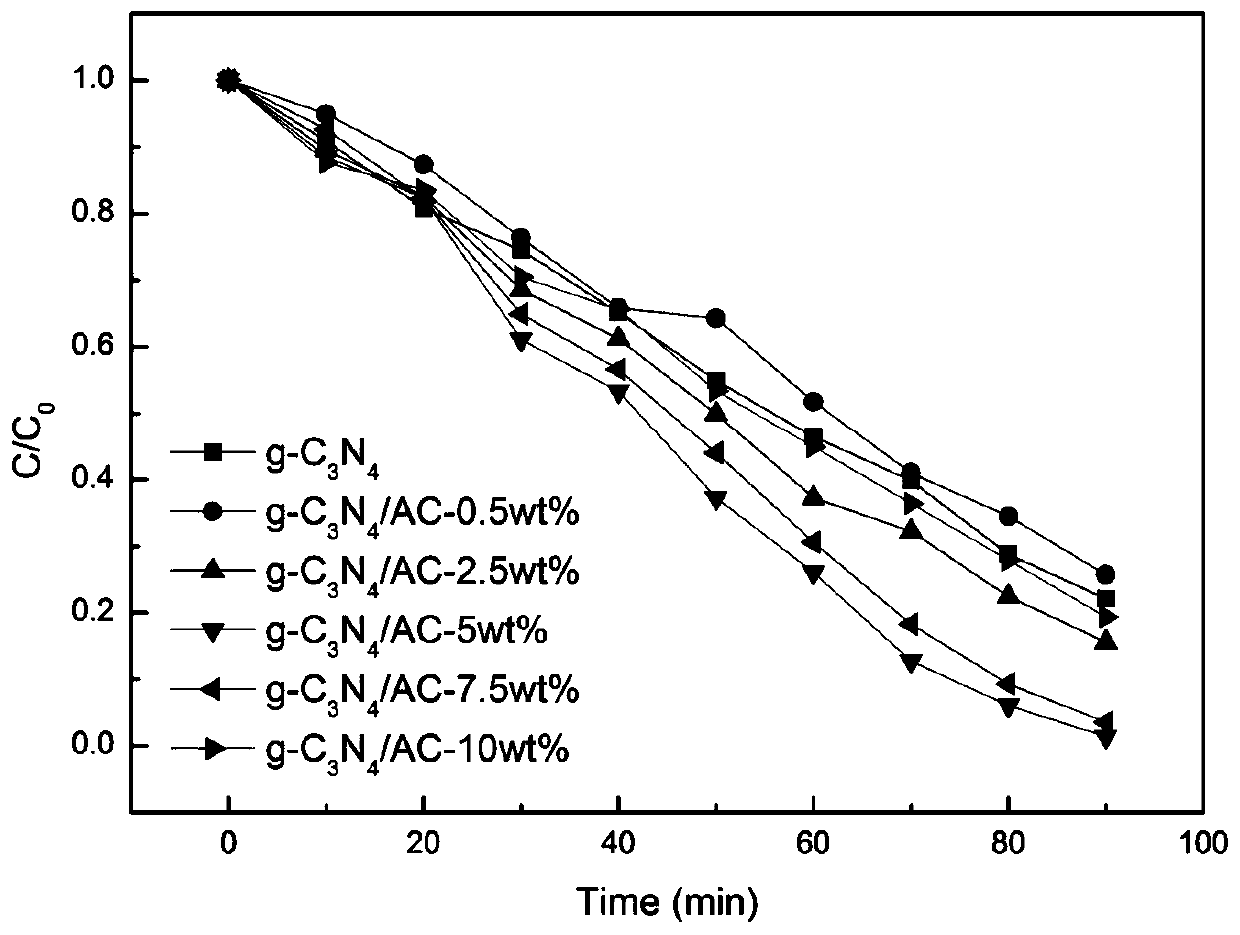

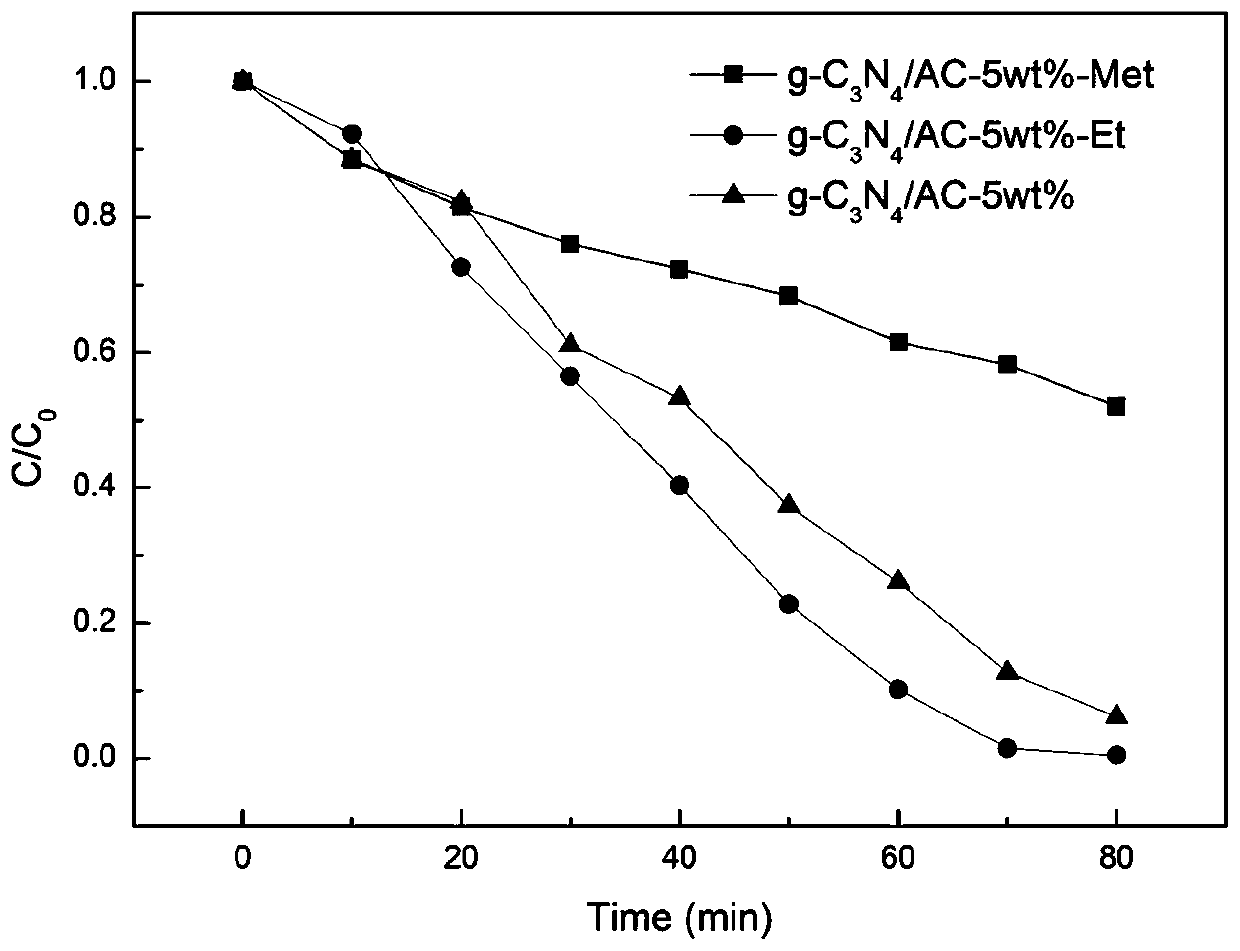

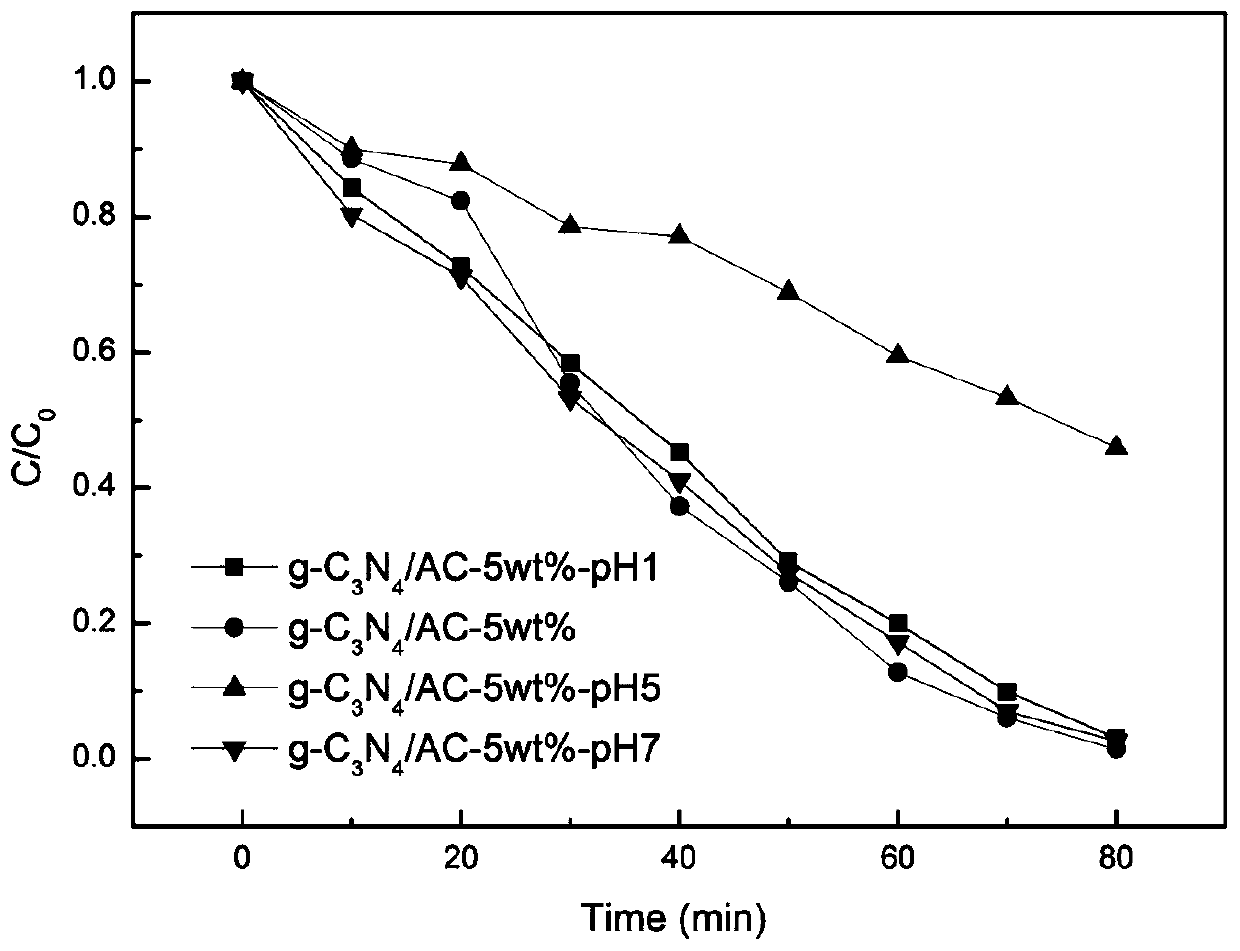

[0045] According to g-C 3 N 4 The mass ratio of the powder to the activated carbon powder is 1: 0.5% to 10%, and the ingredients are mixed to obtain a mixture; the mixture is added to ultrapure water, anhydrous methanol or anhydrous ethanol, stirred, and the pH of the mixture is adjusted to 1~ 7. Then ultrasonicate the mixed solution for 2 hours to obtain a complete mixed solution; put the complete mixed solution into an autoclave, put it in a vacuum drying ov...

Embodiment 1

[0047] Put dicyandiamide into a muffle furnace for calcination, wherein the calcination temperature is 550°C, after the muffle furnace rises to the calcination temperature at a heating rate of 5°C / min, keep it warm for 3 hours, then cool naturally, and the solid material obtained by calcination Grinding to obtain g-C 3 N 4 powder.

[0048] Press g-C 3 N 4 The mass ratio of powder:activated carbon powder is 1:0.5% batching and mixing to obtain a mixture. The mixture was added into ultrapure water, stirred, and the pH of the mixture was adjusted to 3, and then the mixture was sonicated for 2 h to obtain a complete mixture. Pour the complete mixture into an autoclave, put it in a vacuum drying oven, and keep it warm at 180°C for 4 hours. After cooling to room temperature, take out the solution in the autoclave and bake it at 90°C for 9 hours to obtain AC / g -C 3 N 4 Composite photocatalytic material, i.e. g-C 3 N 4 / AC-0.5wt% composite photocatalytic material.

Embodiment 2

[0050] Put dicyandiamide into a muffle furnace for calcination, wherein the calcination temperature is 550°C, after the muffle furnace rises to the calcination temperature at a heating rate of 5°C / min, keep it warm for 3 hours, then cool naturally, and the solid material obtained by calcination Grinding to obtain g-C 3 N 4 powder.

[0051] Press g-C 3 N 4 The mass ratio of powder: activated carbon powder is 1: 2.5% batching and mixing to obtain a mixture. The mixture was added into ultrapure water, stirred, and the pH of the mixture was adjusted to 3, and then the mixture was sonicated for 2 h to obtain a complete mixture. Pour the complete mixture into an autoclave, put it in a vacuum drying oven, and keep it warm at 180°C for 4 hours. After cooling to room temperature, take out the solution in the autoclave and bake it at 90°C for 9 hours to obtain AC / g -C 3 N 4 Composite photocatalytic material, i.e. g-C 3 N 4 / AC-2.5wt% composite photocatalytic material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com