Super-hydrophobic ultralow-density high-strength polystyrene microsphere and preparation method thereof

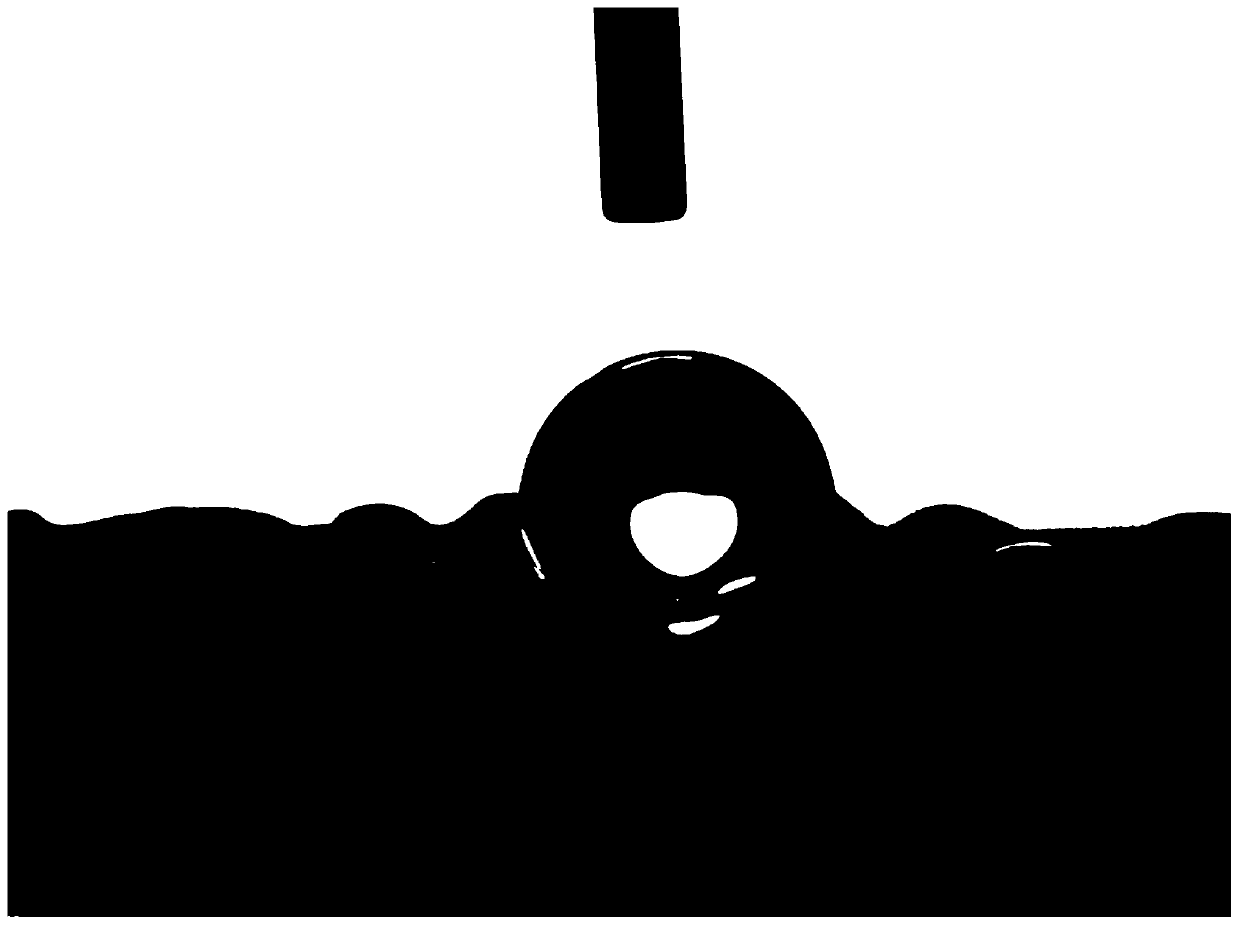

A technology of polystyrene microspheres and ultra-low density, applied in the field of functional polymer materials, can solve the problems of easy breakage, low roundness and sphericity, high fluid viscosity, etc., and achieve strong hydrophobicity, low production cost and low dosage low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

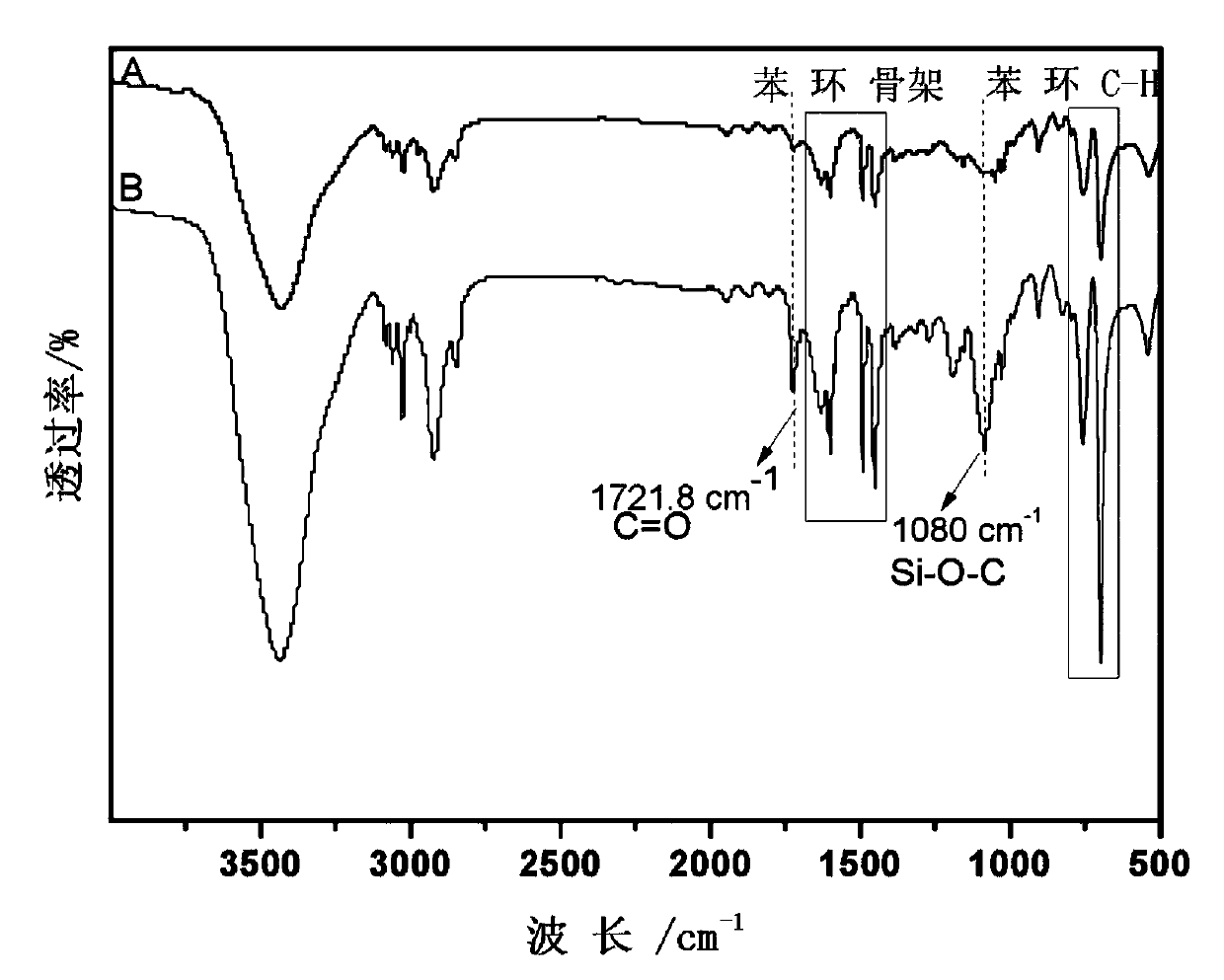

Method used

Image

Examples

preparation example Construction

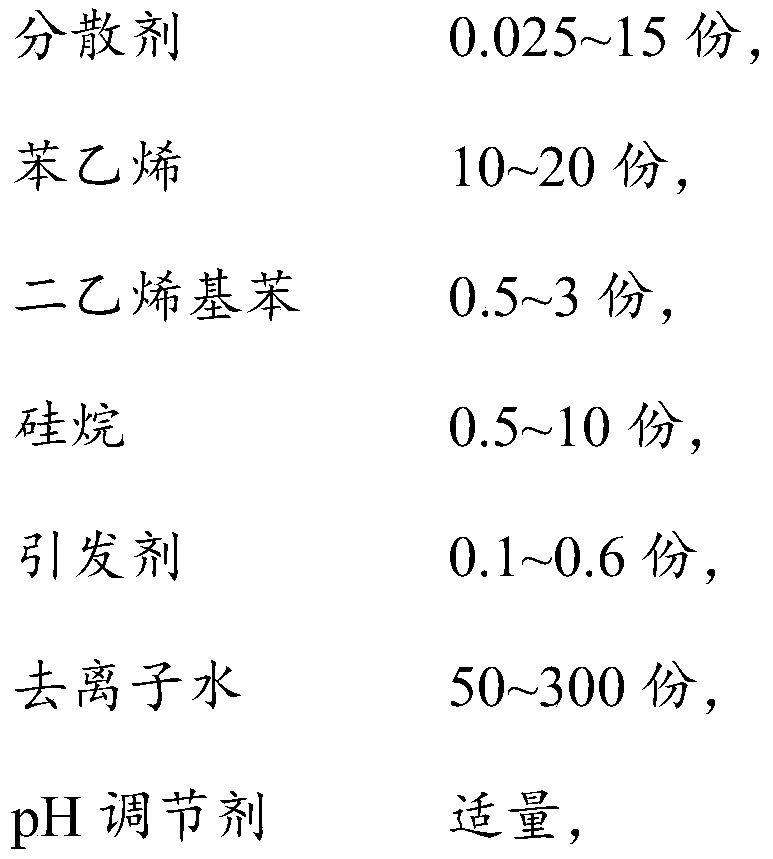

[0041] The preparation method of super-hydrophobic ultra-low-density high-strength polystyrene microspheres, the steps include

[0042] a. Dissolve the dispersant in deionized water to obtain the water phase, and configure the concentration of 0.05-5%;

[0043] b. Premixing styrene, divinylbenzene, silane and initiator to obtain an oil phase;

[0044] c. Slowly add the oil phase to the water phase. During the addition process, control the stirring speed to 40-200rpm and the temperature to 40-60°C until all the oil phase is added to the water phase;

[0045] d. After all the oil phase is added to the water phase, control the stirring speed at 60-240rpm, add ammonia water to adjust the pH value to 8-12, heat up to 65-100°C and react for 1-5 hours;

[0046] e. Suction filtration and washing to obtain super-hydrophobic, ultra-low-density, high-strength polystyrene microspheres.

[0047] The preparation process of the polystyrene microspheres that is used for comparative test is si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com