Lubricating oil additive with core-shell structure, preparation method thereof and lubricating oil

A technology of lubricating oil additive and core-shell structure is applied in the field of lubricating oil, which can solve the problems of insufficient performance of lubricating oil, and achieve the effect of reducing friction coefficient and wear rate, low cost and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of a lubricating oil additive with a core-shell structure, comprising the following steps:

[0036] S1: Add 0.1-0.5 g of hard nanoparticles constituting the core to 20-40 ml of ethylene glycol, stir or sonicate to mix the components evenly;

[0037] Preferably, the particle size of the hard nanoparticles in step S1 is 20-200nm. The particle size of the hard nanoparticles constituting the core directly affects the particle size of the lubricating oil additive. If the particle size is too large, the additive may be stuck between the two sides. Between a frictional machine;

[0038] Preferably, the material of the hard nanoparticles in step S1 is selected from oxide particles or nitride particles of metals such as silicon dioxide, silicon nitride, titanium dioxide, tungsten carbide, and ceramic particles;

[0039] S2: Add the flexible metal ion compound and polyethylene glycol to the mixed solution in step S1, and m...

Embodiment 1

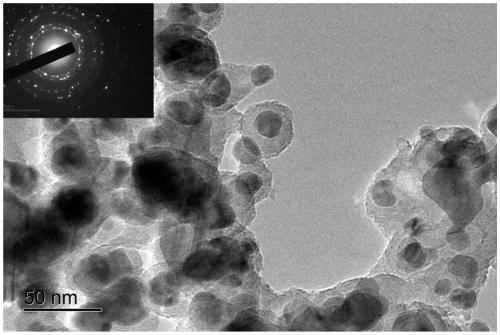

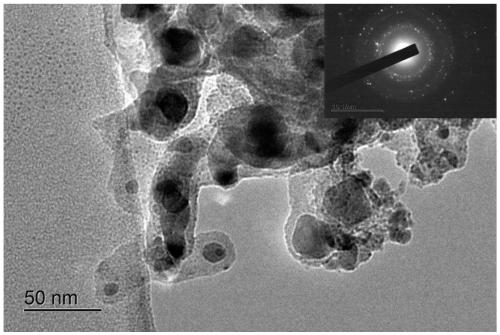

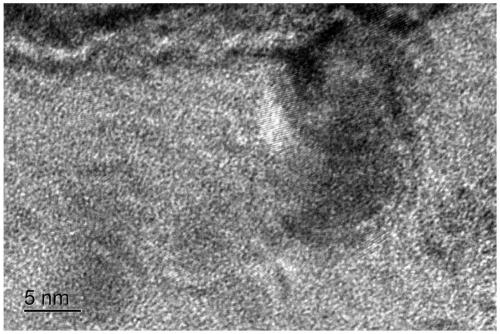

[0051] A SiO 2 @Cu core-shell lubricating oil additives, including SiO 2 The composed core and the copper shell wrapped around the core.

Embodiment 2

[0053] A kind of Si 3 N 4 @Cu core-shell lubricating oil additives, including Si 3 N 4 The composed core and the copper shell wrapped around the core.

[0054] In the above two embodiments, silicon dioxide and silicon nitride are used as the core, and flexible metal copper is used as the shell layer. Silicon dioxide and silicon nitride have good chemical stability and high wear resistance, and are often used as lubricants. Oil nano-additives to prevent the wear of the matrix material during the friction process, and due to their good chemical stability, silicon dioxide and silicon nitride are suitable for wide-area and harsh industrial environments. As a common soft metal, copper has the characteristics of good ductility, high thermal conductivity and electrical conductivity. It is often used in the manufacture of cables, electronics and electrical components, but at the same time, copper has a face-centered cubic structure with many sliding surfaces. Excellent material as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com