Renewable modified activated carbon adsorbent and preparation method and application thereof

An activated carbon adsorption and activated carbon technology, which is applied in the field of regenerable modified activated carbon adsorbent and its preparation, can solve the problems of low adsorption efficiency, large-scale practical application limitations, and high processing costs, and achieve low cost and simple production process The effect of high control and high product error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of a Renewable Modified Activated Carbon Adsorbent

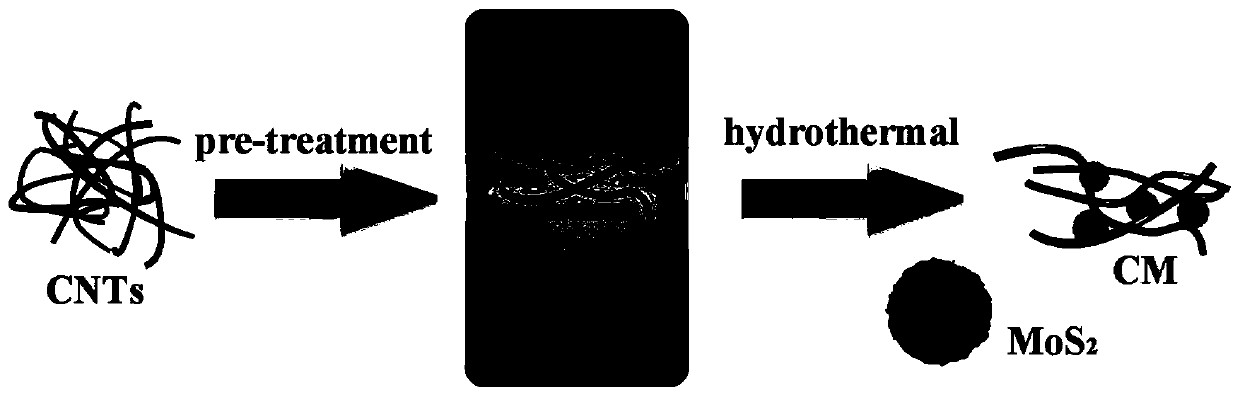

[0030] (1) Modification of carbon nanotubes

[0031] Add 0.3g of multi-walled carbon nanotubes (with an inner diameter of 5-10nm, an outer diameter of 10-20nm, and a length of 0.5-2μm) into 30mL of HNO3 (69%) solution, ultrasonically transfer to a 50mL stainless steel reaction kettle after 0.5h, Incubate at 100°C for 1h. After naturally cooling to room temperature, the product was repeatedly washed with deionized water and ethanol until clean, and dried in vacuum to obtain modified carbon nanotubes.

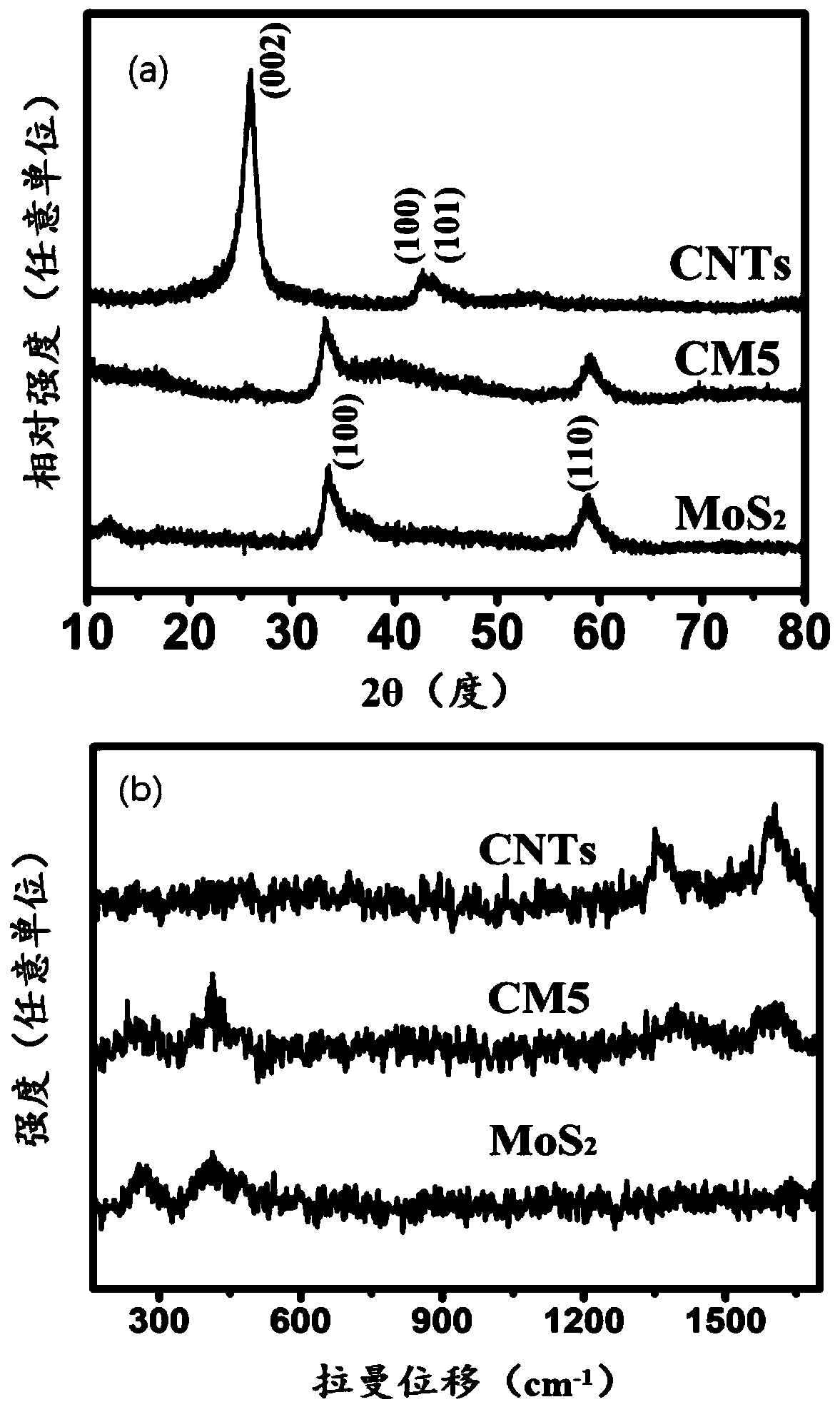

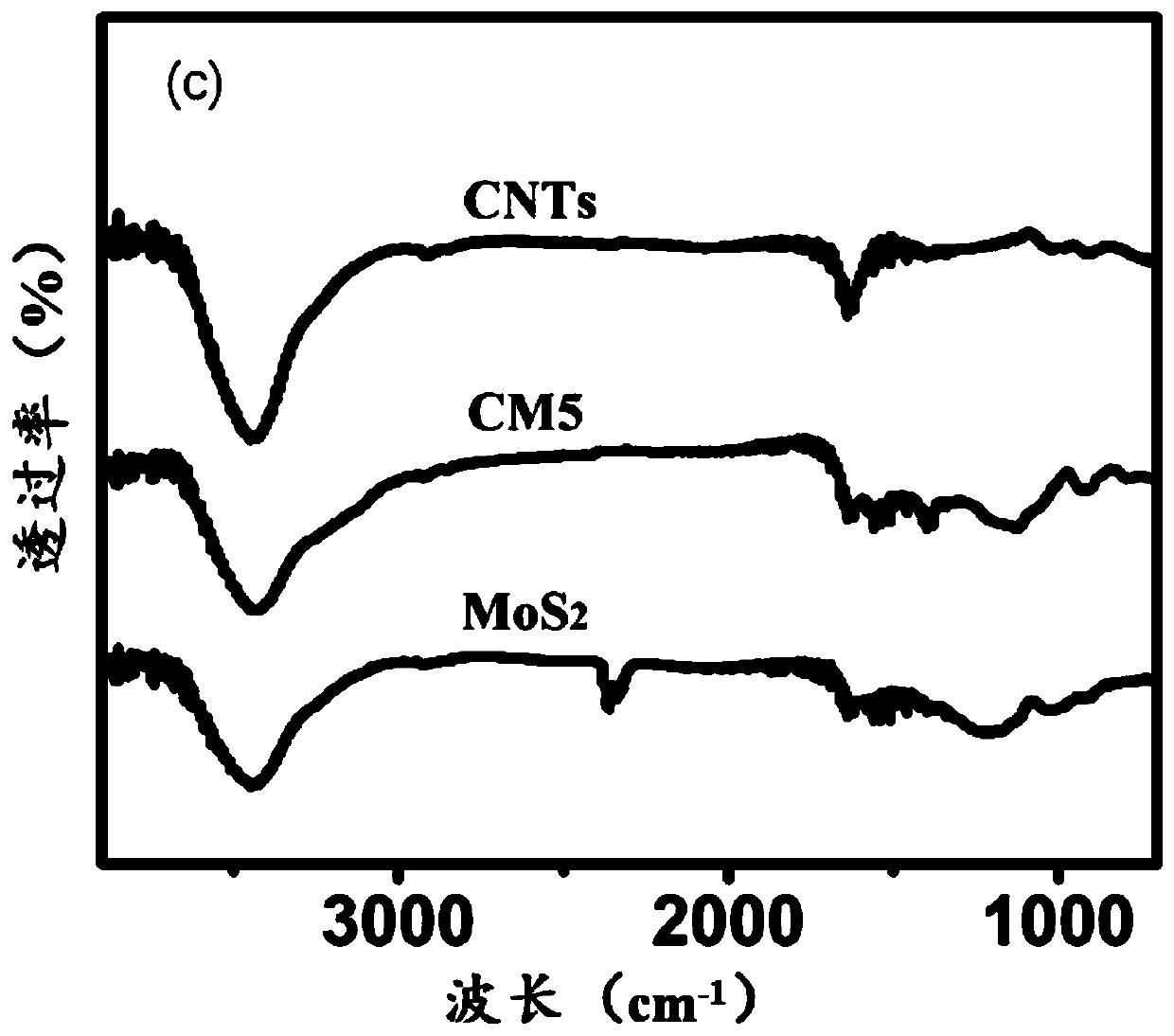

[0032] (2) Preparation of molybdenum disulfide / carbon nanotube composites

[0033] Disperse 20 mg of the modified carbon nanotubes obtained in (1) into 30 mL of deionized water to form a suspension, then add 0.8 g of ammonium molybdate tetrahydrate, 3.6 g of thiourea, and 2.2 g of polyvinylpyrrolidone to the suspension After magnetically stirring for 30 minutes, it was transferred to a 50mL stainless steel...

Embodiment 2

[0037] Preparation of a Renewable Modified Activated Carbon Adsorbent

[0038] (1) Modification of carbon nanotubes

[0039] Add 0.3g of multi-walled carbon nanotubes (with an inner diameter of 5-10nm, an outer diameter of 10-20nm, and a length of 0.5-2μm) into 30mL of HNO3 (69%) solution, ultrasonically transfer to a 50mL stainless steel reaction kettle after 0.5h, Incubate at 100°C for 1h. After naturally cooling to room temperature, the product was repeatedly washed with deionized water and ethanol until clean, and dried in vacuum to obtain modified carbon nanotubes.

[0040] (2) Preparation of molybdenum disulfide / carbon nanotube composites

[0041] Disperse 20 mg of the modified carbon nanotubes obtained in (1) into 30 mL of deionized water to form a suspension, then add 0.4 g of ammonium molybdate tetrahydrate, 1.8 g of thiourea, and 1.1 g of polyvinylpyrrolidone to the suspension After magnetically stirring for 30 minutes, it was transferred to a 50mL stainless steel...

Embodiment 3

[0045] Preparation of a Renewable Modified Activated Carbon Adsorbent

[0046] (1) Modification of carbon nanotubes

[0047] Add 0.3g of multi-walled carbon nanotubes (with an inner diameter of 5-10nm, an outer diameter of 10-20nm, and a length of 0.5-2μm) into 30mL of HNO3 (69%) solution, ultrasonically transfer to a 50mL stainless steel reaction kettle after 0.5h, Incubate at 100°C for 1h. After naturally cooling to room temperature, the product was repeatedly washed with deionized water and ethanol until clean, and dried in vacuum to obtain modified carbon nanotubes.

[0048] (2) Preparation of molybdenum disulfide / carbon nanotube composites

[0049] Disperse 20 mg of the modified carbon nanotubes obtained in (1) into 30 mL of deionized water to form a suspension, then add 0.2 g of ammonium molybdate tetrahydrate, 0.9 g of thiourea, and 0.55 g of polyvinylpyrrolidone to the suspension After magnetically stirring for 30 minutes, it was transferred to a 50mL stainless steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com