A kind of solid catalyst and its preparation method and application

A solid catalyst and solid technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unsatisfactory efficiency and low graphite yield, and achieve good results and high graphite yield High, chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

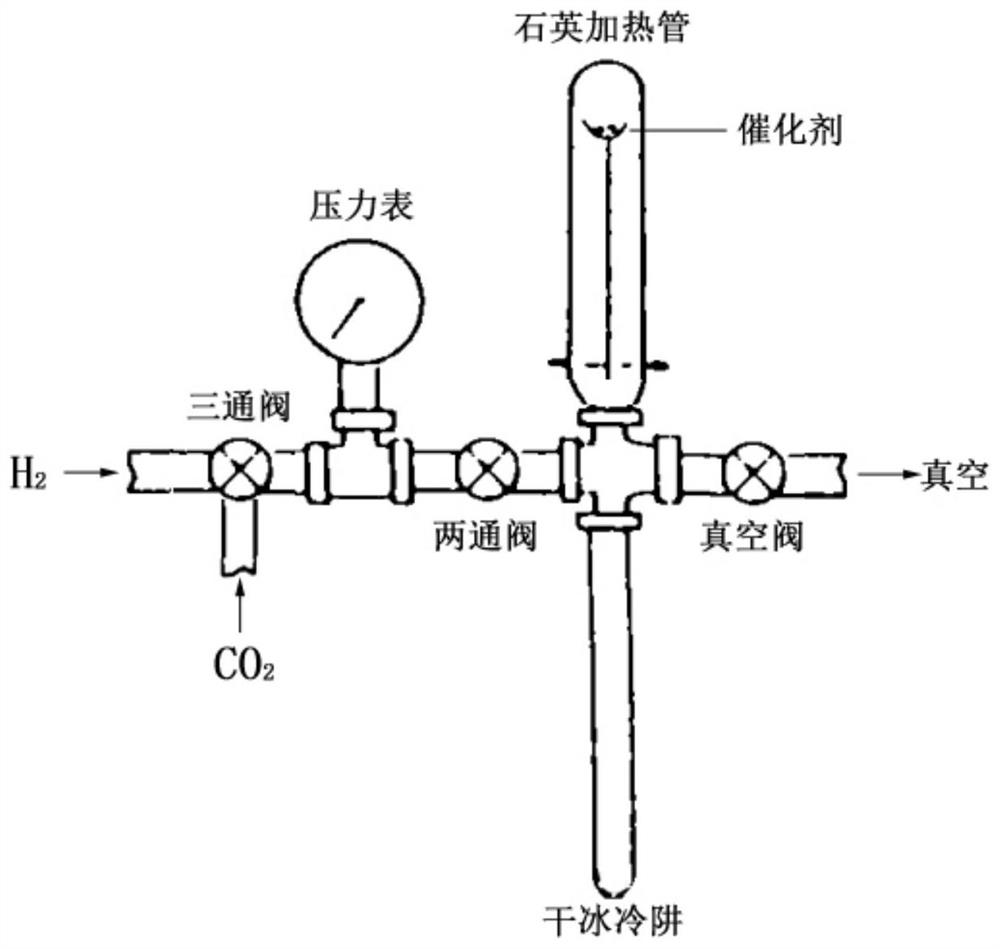

Image

Examples

preparation example Construction

[0031] A second aspect of the present invention provides a preparation method of the above-mentioned solid catalyst, the preparation method comprising:

[0032] (1) mixing the solution of Group VIII metal soluble precursor with the adsorbent, dispersing uniformly to obtain a mixed system;

[0033] (2) remove the liquid phase and roasting in the mixed system to obtain the treated solid;

[0034] (3) the solid after described treatment is carried out contact reaction with hydrogen, obtains the solid after reduction;

[0035] (4) Co-grinding the reduced solid and a carbon-free grinding aid to obtain the solid catalyst.

[0036] In the present invention, the solvent in the solution of the group VIII metal soluble precursor can be any solvent suitable for dissolving the group VIII metal precursor, such as water, ethanol and the like.

[0037] According to the present invention, preferably, the calcination temperature in step (2) is 100-800°C; the contact reaction temperature in s...

Embodiment 1

[0065] 1) Weigh 7.2g Fe (NO 3 ) 3 ·9H 2 O (analytical pure), add an appropriate amount of deionized water to dissolve;

[0066] 2) Weigh 10 g of diatomaceous earth, add it to the solution obtained in step 1), ultrasonically treat it to form a dispersion system, and stir overnight;

[0067] 3) Under the stirring state, slowly evaporate the mixed suspension system obtained in step 2) to dryness, collect the solid remaining after evaporation to dryness, transfer the solid to a porcelain boat, place it in a muffle furnace, and bake it at 200° C. for 3 hours;

[0068] 4) The solid roasted in step 3) is transferred to the tube furnace together with the porcelain boat, and the heating tube is passed into nitrogen. After the air in the container is exhausted, the nitrogen flow is replaced with hydrogen, and the nitrogen is exhausted side by side, and the system is heated. to 250°C for 2h; after cooling, the hydrogen flow was replaced with nitrogen, the hydrogen was exhausted, and t...

Embodiment 2

[0073] 1) Weigh 0.5 g of chloroplatinic acid (analytical grade, platinum content 38%), add an appropriate amount of deionized water, and stir until completely dissolved;

[0074] 2) Weigh 10 g of γ-alumina, add it to the solution obtained in step 1), ultrasonically treat it to form a dispersion system, and stir overnight;

[0075] 3) filter the mixed suspension system obtained in step 2) to collect solid;

[0076] 4) Weigh 0.5 g of chloroplatinic acid (analytical purity, platinum content 38%), add an appropriate amount of deionized water, and stir until completely dissolved;

[0077] 5) adding the solid obtained in step 3) to the solution obtained in step 4), ultrasonically treating it to form a dispersion system, and stirring overnight;

[0078] 6) filter the mixed suspension system obtained in step 5) to collect the solid; transfer the solid to a porcelain boat, place it in a muffle furnace, and bake at 250° C. for 2 hours;

[0079] 7) The solid roasted in step 6) is trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com