Safe, environment-friendly and cheap method and device for producing deuterated aromatic ring compound

An aromatic ring compound, safe and environmentally friendly technology, applied in the fields of hydrocarbons, hydrocarbons, organic chemical methods, etc., can solve the problems of inability to commercialize production, expensive aromatic ring compounds, etc., to improve the utilization rate of deuterium and avoid volatilization. Loss, avoidance of effects on human injury and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

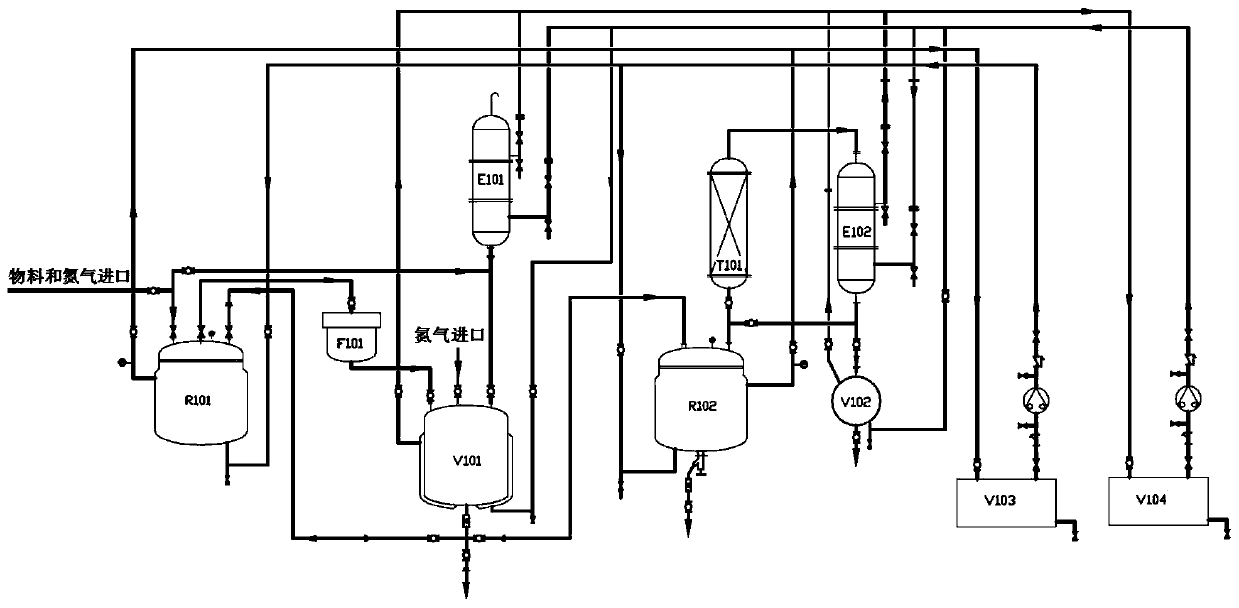

[0040] see Figure 1-3As shown, a safe, environmentally friendly and inexpensive device for producing deuterated aromatic ring compounds provided by the embodiment of the present invention includes an autoclave R101 for deuteration reaction, a liquid separation tank V101 for liquid separation treatment, and a liquid separation tank V101 for the reaction The enamel still R102 for distillation treatment of the final organic phase, the rectification device for the rectification operation of the reaction liquid, the receiving bottle V102 for receiving the product after rectification, and the heat exchange device for providing heat transfer medium,

[0041] The top of the autoclave R101 is equipped with a material inlet and an inert gas inlet. The liquid outlet of the autoclave R101 is connected to the liquid separation tank V101 through the pressure filter F101. The liquid outlet is provided with a control valve, the bottom of the control valve is provided with an aqueous phase li...

Embodiment 2

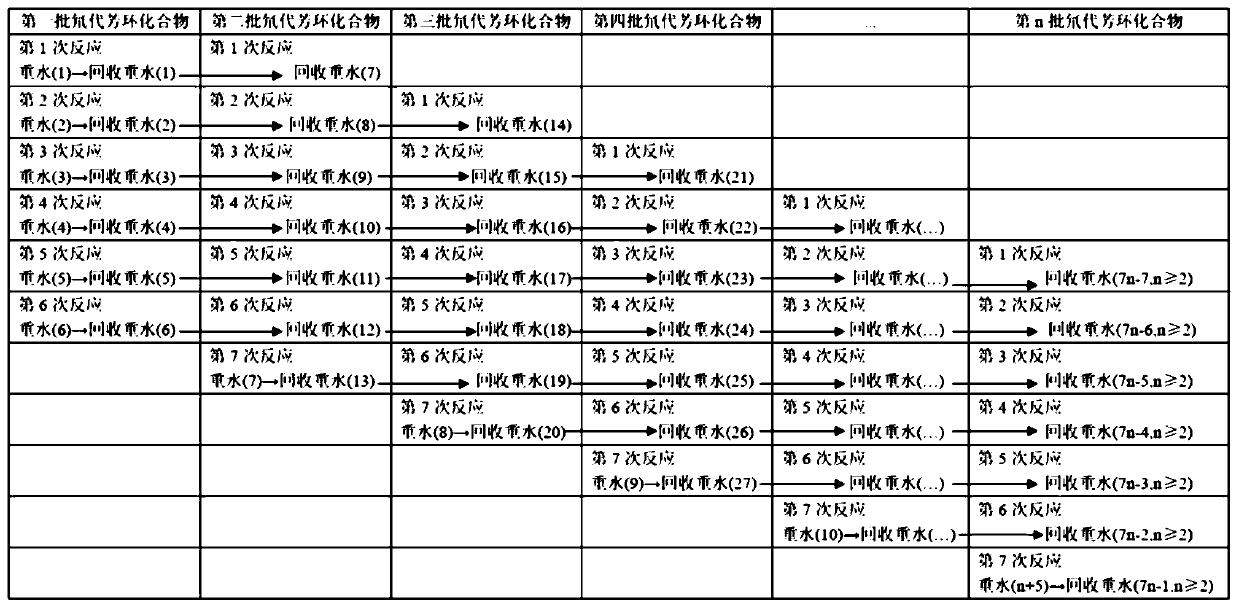

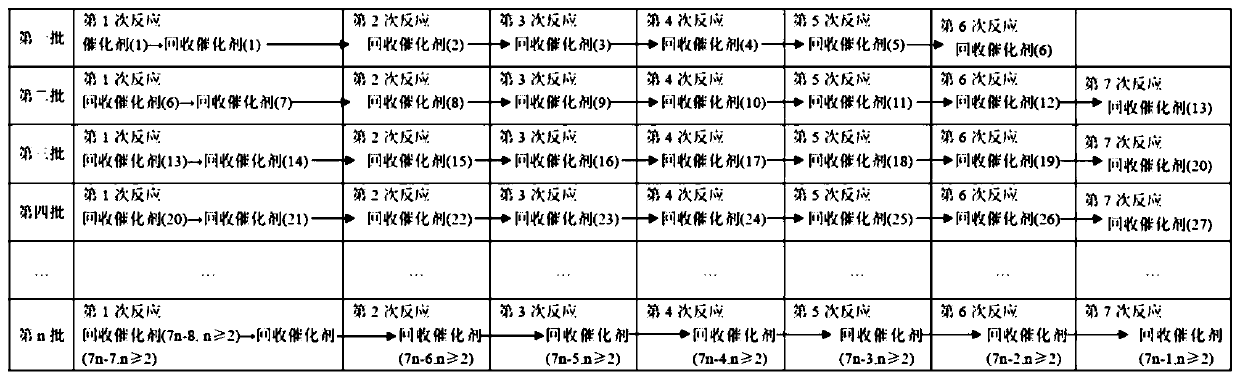

[0065] The difference from the above examples is that the equipment for avoiding product volatilization loss and the experimental scheme for recovering deuterated heavy water are used at the same time. The specific operation steps are as follows:

[0066] Preparation of the second batch of deuterated benzene:

[0067] The first reaction: In the 2000L R101 autoclave, add recovered heavy water (1), catalyst 10% Pd / C 36kg and benzene 528Kg. After the feeding is completed, the autoclave R101 is sealed, stirred and heated to 180°C for reaction, and kept at 180°C for 4 hours. Turn off the heating, and cool down to 15°C through the V103 oil tank cold oil. Open the discharge valve, under stirring, use nitrogen gas to press the reaction solution from the discharge port into the 2000L V101 liquid separation tank through the F101 pressure filter, and the pressure filtration is completed. Close the nitrogen inlet valve and outlet valve, and open the vent valve of the 2000L R101 autoclave...

Embodiment 3

[0078] The difference from the above examples is that the equipment for avoiding product volatilization loss and the experimental scheme for recovering deuterated heavy water are used at the same time. The specific operation steps are as follows:

[0079] Preparation of the third batch of deuterated benzene:

[0080] The first reaction: in the 2000L R101 autoclave, add reclaimed heavy water (8), catalyst 10%Pd / C 36kg and benzene 528Kg. After the feeding is completed, the autoclave R101 is sealed, stirred and heated to 180°C for reaction, and kept at 180°C for 4 hours. Turn off the heating, and cool down to 15°C through the V103 oil tank cold oil. Open the discharge valve, under stirring, use nitrogen gas to press the reaction solution from the discharge port into the 2000L V101 liquid separation tank through the F101 pressure filter, and the pressure filtration is completed. Close the nitrogen inlet valve and outlet valve, and open the vent valve of the 2000L R101 autoclave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com