Method for preparing tert-butylamine by taking MTBE as raw material

A technology of tert-butylamine and raw materials, which is applied in the field of preparation of tert-butylamine, can solve the problems of low MTBE conversion rate, strong catalyst corrosion, harsh reaction conditions, etc., and achieve high conversion rate, improved reaction efficiency and conversion rate, and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

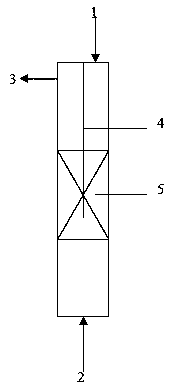

Image

Examples

Embodiment 1

[0037] (1) Preparation of solid superacid catalyst: a: 50 grams of ZrOCl 2 Dissolved in ethanol to obtain a mass concentration of 25% ZrOCl 2 ethanol solution, and then 40 g of AlCl 3 dissolved in ZrOCl 2 In the ethanol solution, titrate with 20% ammonia water until there is no white precipitate, wash with deionized water for 5 times, each time for 10 minutes, the washing temperature is 40°C, wash until there is no chloride ion, and then put it in a vacuum at 90°C Dried in a drying oven for 6 hours, extruded and then calcined at 500° C. for 8 hours to obtain white solid particles for use. b: impregnate the white particles obtained in step 1 with a silver nitrate sulfuric acid solution with a concentration of 2mol / L, the impregnation temperature is 55°C, and the impregnation time is 6h; the decompression vacuum degree is 15000Pa; the ultrasonic vibration frequency is 55kHz, and then the solid particles are placed at 90°C Dry it in a vacuum oven for 6 hours under the conditio...

Embodiment 2

[0040] (1) Preparation of solid superacid catalyst: a: 50 grams of ZrOCl 2 Dissolved in ethanol to obtain a mass concentration of 25% ZrOCl 2 ethanol solution, and then 50 g of AlCl 3 dissolved in ZrOCl 2 In the ethanol solution, titrate with 20% ammonia water until there is no white precipitate, wash with deionized water for 5 times, each time for 10 minutes, the washing temperature is 40°C, wash until there is no chloride ion, and then put it in a vacuum at 90°C Dried in a drying oven for 6 hours, extruded and then calcined at 450° C. for 8 hours to obtain white solid particles for use. b: impregnate the white particles obtained in step 1 with a silver nitrate sulfuric acid solution with a concentration of 2mol / L, the impregnation temperature is 55°C, and the impregnation time is 6h; the decompression vacuum degree is 15000Pa; the ultrasonic vibration frequency is 58kHz, and then the solid particles are placed at 90°C Dry it in a vacuum oven for 6 hours under the conditio...

Embodiment 3

[0043] (1) Preparation of solid superacid catalyst: a: 50 grams of ZrOCl 2 Dissolved in ethanol to obtain a mass concentration of 25% ZrOCl 2 ethanol solution, and then 40 g of AlCl 3 dissolved in ZrOCl 2 In the ethanol solution, titrate with 20% ammonia water until there is no white precipitate, wash with deionized water for 5 times, each time for 10 minutes, the washing temperature is 40°C, wash until there is no chloride ion, and then put it in a vacuum at 90°C Dried in a drying oven for 6 hours, extruded and then calcined at 500° C. for 8 hours to obtain white solid particles for use. b: Impregnate the white particles obtained in step 1 with a silver nitrate sulfuric acid solution with a concentration of 3mol / L, the impregnation temperature is 55°C, and the impregnation time is 6h; the decompression vacuum degree is 15000Pa; the ultrasonic vibration frequency is 55kHz, and then the solid particles are placed at 90°C Dry it in a vacuum oven for 6 hours under the conditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com