Epoxy resin composition

A technology of epoxy resin and epoxy resin layer, which is applied in the field of composite materials, can solve problems such as easy fracture and collapse, weak rigidity, and low melting point, and achieve the effect of improving surface hardness, enhancing toughness, and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

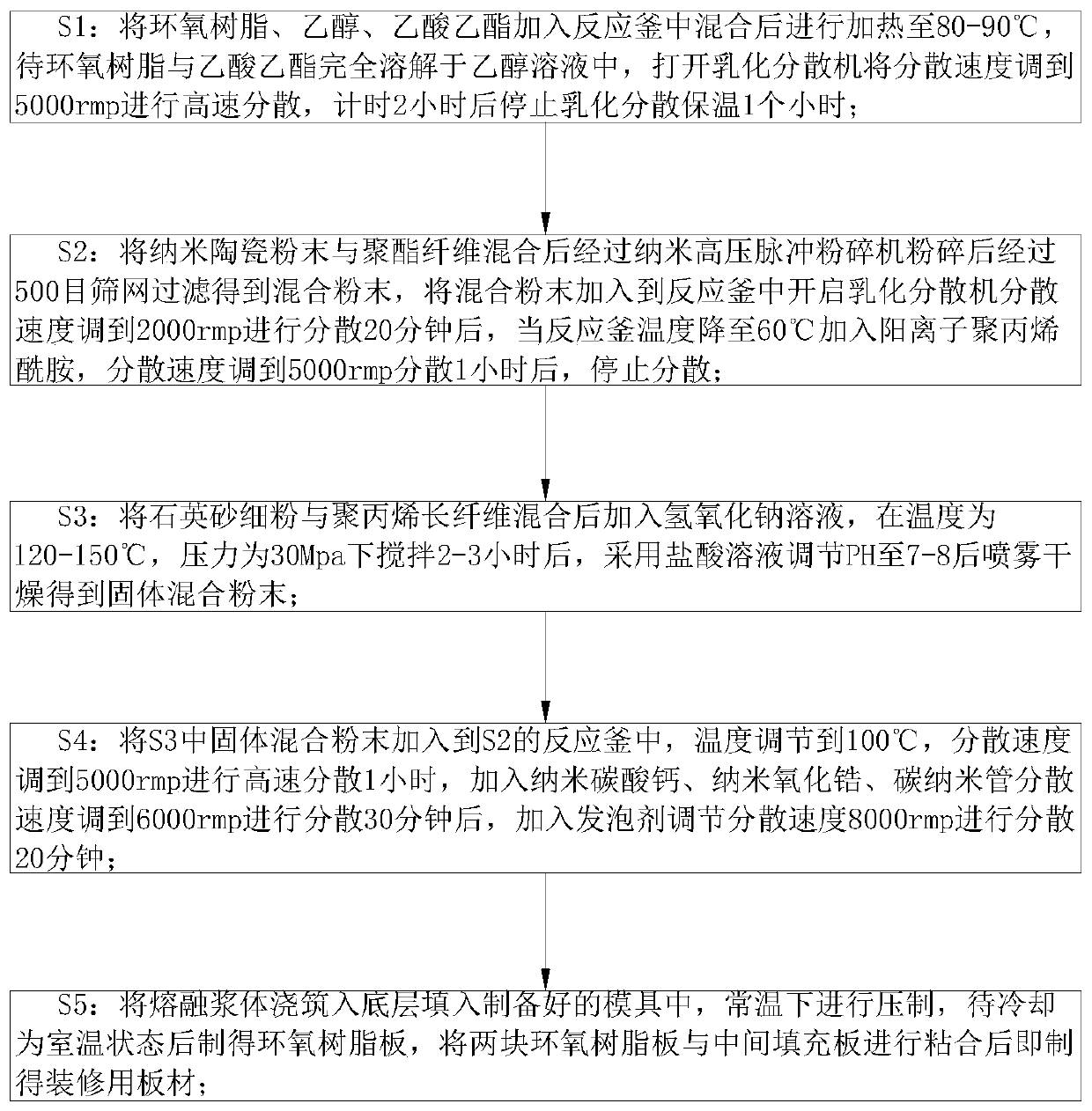

[0038] This epoxy resin composition preparation method comprises the following steps:

[0039] S1: Add epoxy resin, ethanol, and ethyl acetate into the reaction kettle and mix, then heat to 80-90°C. After the epoxy resin and ethyl acetate are completely dissolved in the ethanol solution, turn on the emulsifying disperser and adjust the dispersion speed to 5000rmp for high-speed dispersion, stop emulsification and dispersion after 2 hours of timing and keep warm for 1 hour;

[0040] S2: After mixing the nano-ceramic powder and polyester fiber, it is pulverized by a nano-high-pressure pulse mill and then filtered through a 500-mesh screen to obtain a mixed powder. The mixed powder is added to the reaction kettle and the emulsification disperser is turned on. The dispersion speed is adjusted to 2000rmp for dispersing for 20 Minutes later, when the temperature of the reactor drops to 60°C, add cationic polyacrylamide, adjust the dispersion speed to 5000rmp and disperse for 1 hour,...

Embodiment approach

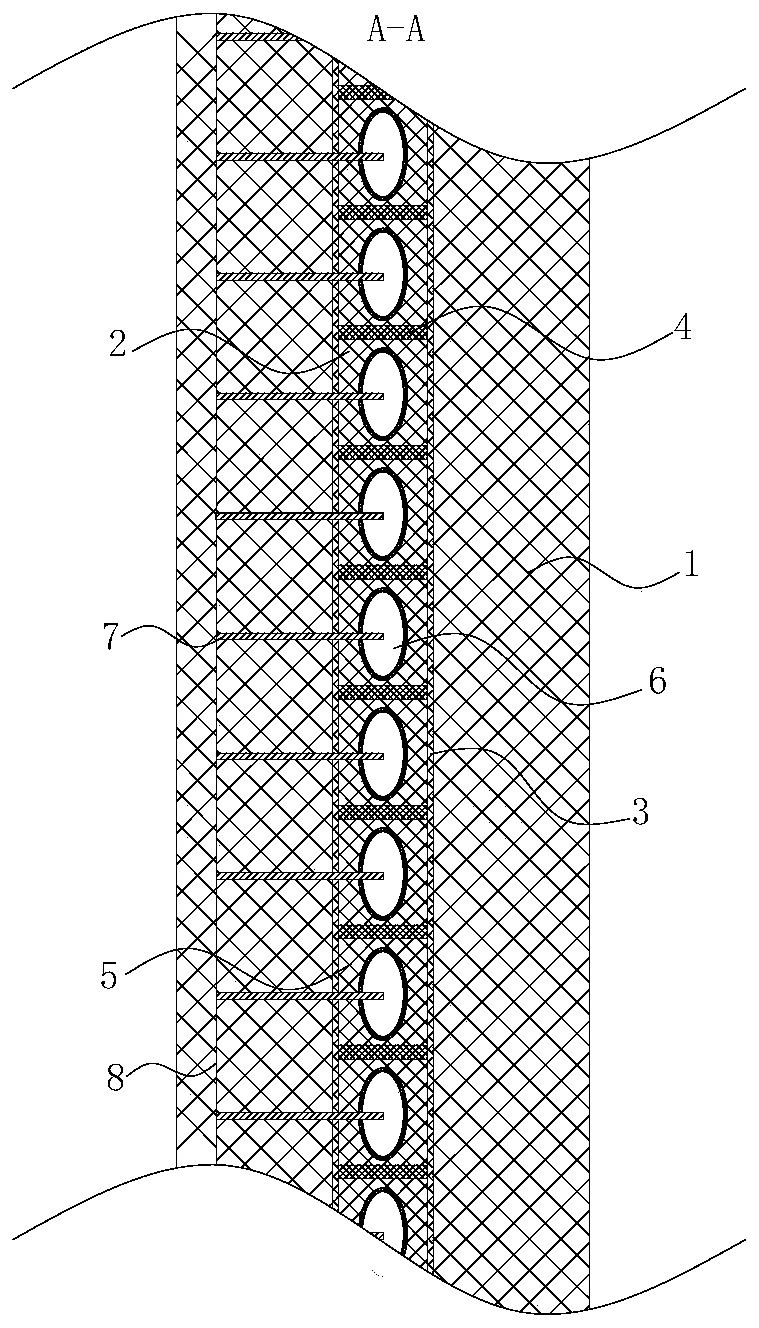

[0052] As an embodiment of the present invention, the decoration plate includes an epoxy resin layer 1 and a filling layer 2; the number of the epoxy resin layer 1 is two and the filling layer 2 is located between the two epoxy resin layers 1; The epoxy resin layer 1 is fixed with glass fiber cloth 3 near the side of the filling layer 2; the filling layer 2 includes a support frame 4 and a sound-absorbing sponge 5; the support frame 4 has a honeycomb structure; the sound-absorbing sponge 5 It is filled inside the honeycomb of the support frame 4; the sound-absorbing sponge 5 is fixed with uniformly arranged rubber capsules 6; the interior of the rubber capsule 6 is filled with water; the surface of the rubber capsule 6 is provided with micropores, and the micropores in the initial state in a closed state;

[0053] During work, the epoxy resin layer 1 is poured on both sides of the filling layer 2 to obtain a plate, which is used for decoration. When a fire breaks out, the envi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com