Insulating flame-retardant potting mixture and preparation method thereof

A mixture and potting technology, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high unit price of high-end flame retardant epoxy, high energy consumption, and increased use cost of enterprises , to prevent toxic gases and corrosive odors, reduce the cost of use, good flame retardant and smoke suppression effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for an insulating flame-retardant potting mixture, comprising the following steps:

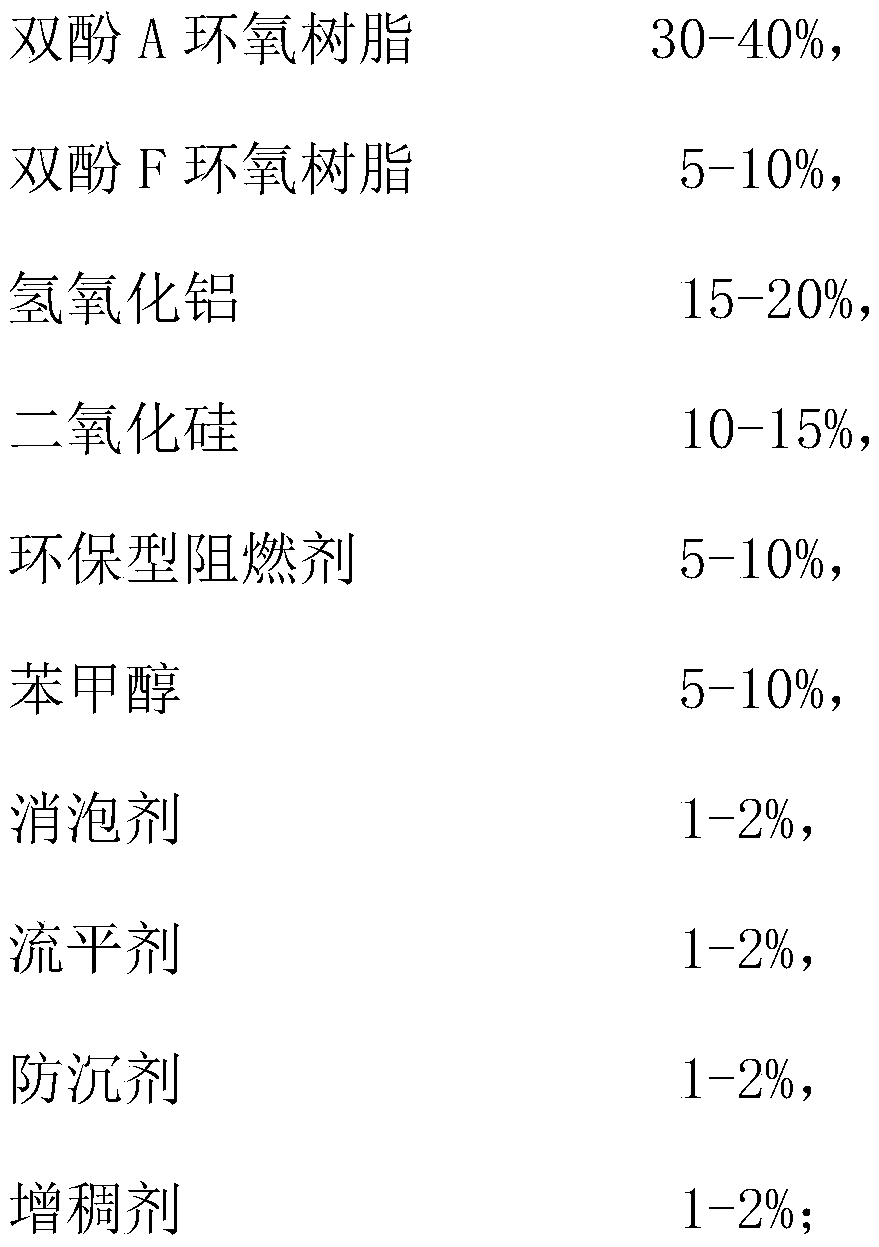

[0030] Step 1, preparation of agent A: take the following raw materials in proportion by mass percentage, bisphenol A epoxy resin 36%, bisphenol F epoxy resin 9%, aluminum hydroxide 18%, silicon dioxide 13%, hypophosphorous acid Aluminum 9%, benzyl alcohol 8%, defoamer 2%, leveling agent 2%, anti-settling agent 1%, thickener 2%; first mix bisphenol A epoxy resin and bisphenol F epoxy resin Evenly, add aluminum hydroxide and silicon dioxide to it, move to the disperser to disperse until its fineness is within 100 microns; add aluminum hypophosphite and transfer to the emulsifier for emulsification, the speed of the emulsifier is 1000 rpm Minutes; emulsify the material to heat up, measure the temperature, add defoamer, leveling agent, anti-settling agent, benzyl alcohol after the temperature reaches 110 degrees, test its viscosity after adding, if the viscosity is not...

Embodiment 2

[0034] A preparation method for an insulating flame-retardant potting mixture, comprising the following steps:

[0035] Step 1, preparation of agent A: take the following raw materials by mass percentage, 30% of bisphenol A epoxy resin, 10% of bisphenol F epoxy resin, 20% of aluminum hydroxide, 15% of silicon dioxide, zinc borate 10%, benzyl alcohol 10%, defoamer 1%, leveling agent 1%, anti-settling agent 2%, thickener 1%; first mix bisphenol A epoxy resin and bisphenol F epoxy resin and stir well , then add aluminum hydroxide and silicon dioxide to it, move to a disperser to disperse until its fineness is within 100 microns; add zinc borate and transfer to an emulsifier for emulsification, and the speed of the emulsifier is 1000 rpm; Emulsify to heat up the material, measure the temperature, add defoamer, leveling agent, anti-settling agent, benzyl alcohol after the temperature reaches 110 degrees, test its viscosity after adding, if the viscosity is not enough, add a thicken...

Embodiment 3

[0039] A preparation method for an insulating flame-retardant potting mixture, comprising the following steps:

[0040] Step 1, preparation of agent A: Weigh the following raw materials by mass percentage, bisphenol A epoxy resin 40%, bisphenol F epoxy resin 5%, aluminum hydroxide 19%, silicon dioxide 12%, melamine 8% %, benzyl alcohol 9%, defoamer 2%, leveling agent 2%, anti-settling agent 1.5%, thickener 1.5%; first mix bisphenol A epoxy resin and bisphenol F epoxy resin evenly, Add aluminum hydroxide and silicon dioxide therein again, move to disperser and disperse to its fineness in the scope of 100 microns; Add melamine and transfer to emulsifying machine for emulsification, the rotating speed of emulsifying machine is 1000 rev / min; Heat up the material, measure the temperature, add defoamer, leveling agent, anti-settling agent, benzyl alcohol after the temperature reaches 110 degrees, test its viscosity after adding, if the viscosity is not enough, add a thickener to mak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com