Three-dimensional porous self-supporting electrode and preparation and application thereof

A self-supporting electrode, three-dimensional porous technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of inability to large-scale industrial application, small output, and long preparation time, and is suitable for large-scale production. The effect of electrical conductivity and short flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

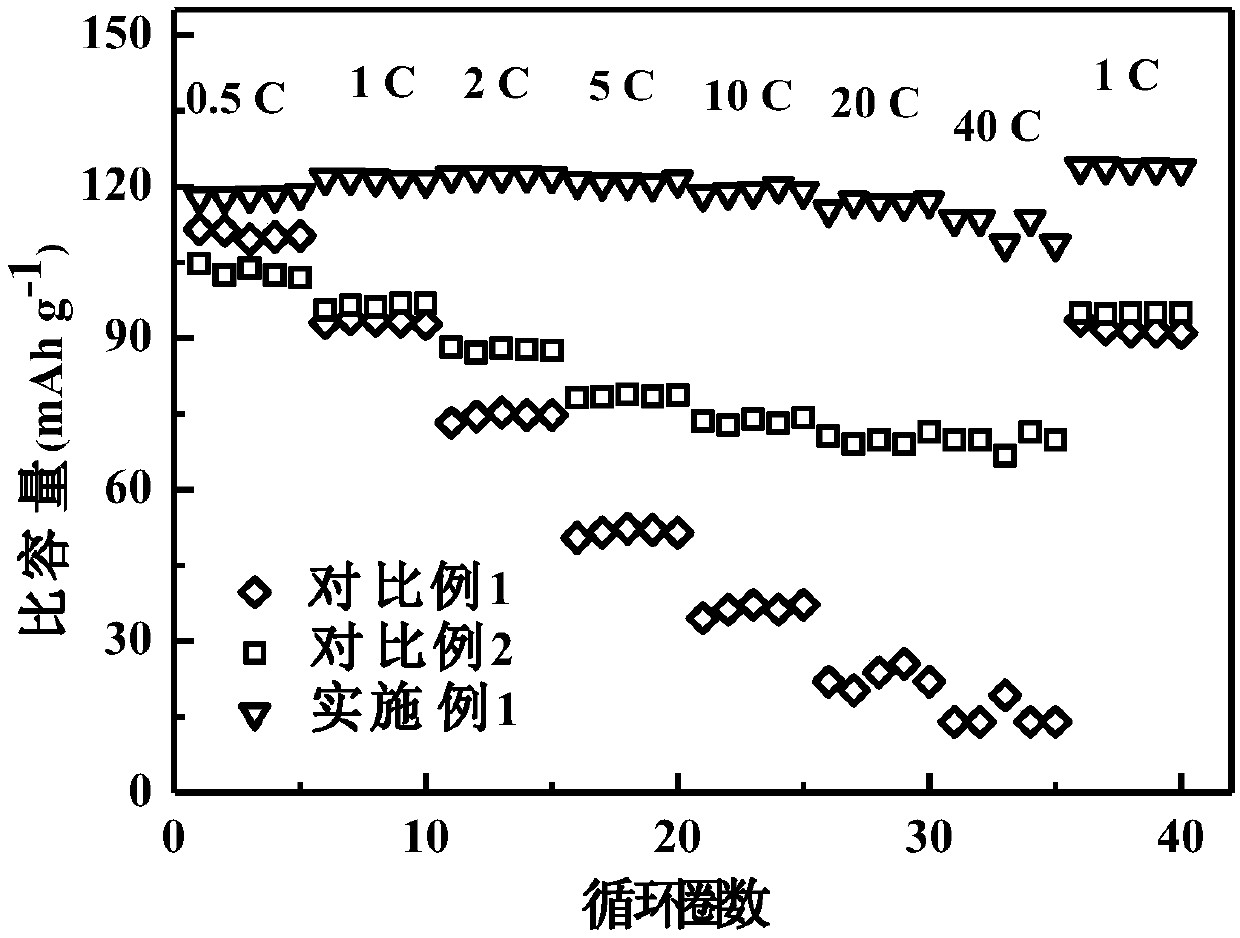

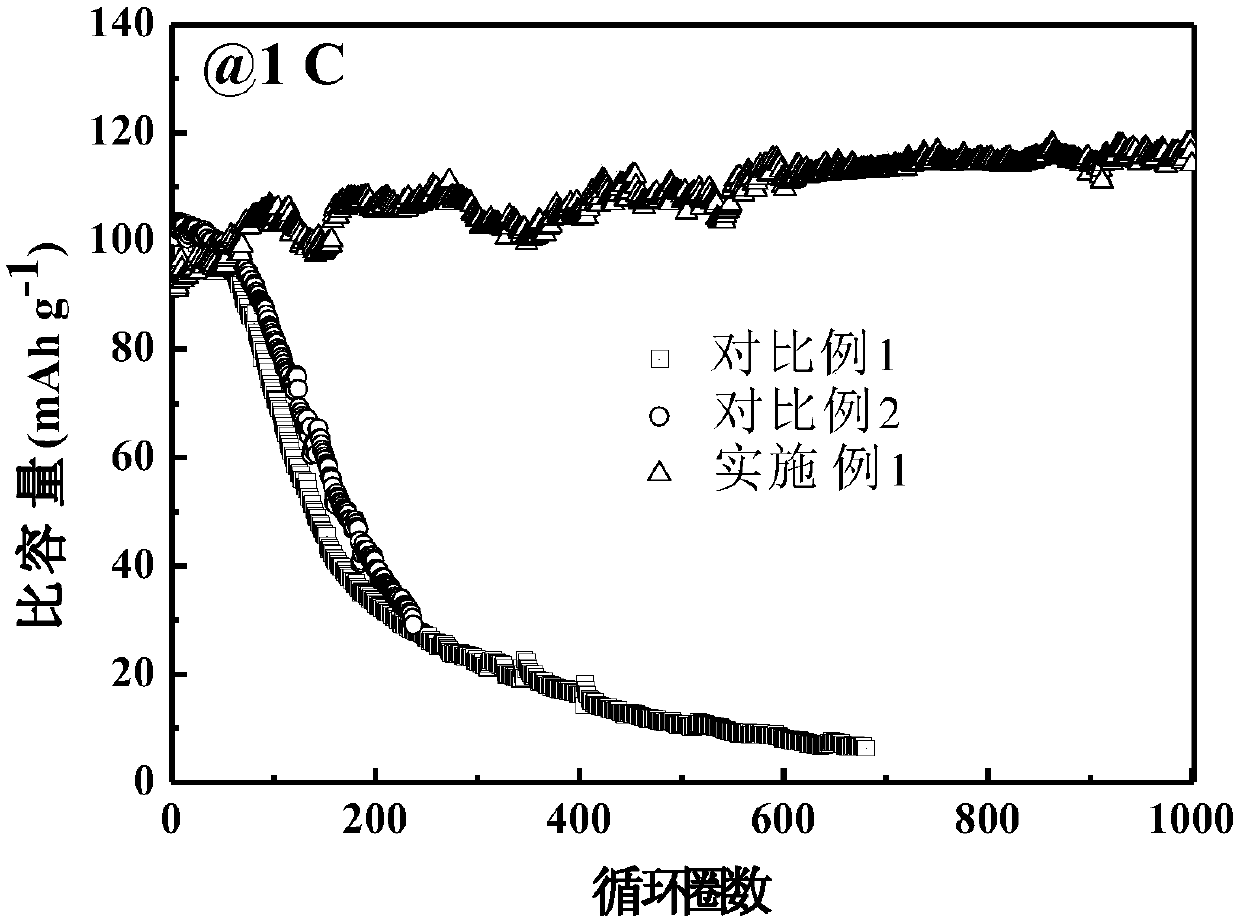

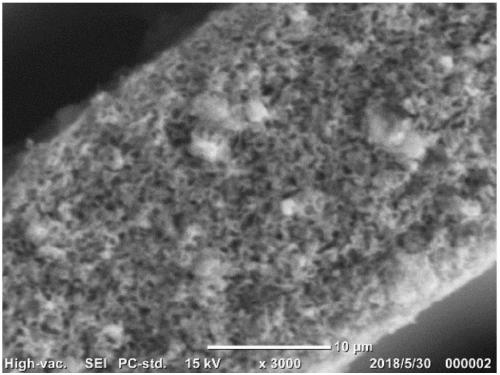

[0038]Embodiment 1: (preparation Na 3 V 2 (PO 4 ) 3 @3DPC-1 self-supporting electrode)

[0039] Weighed 0.8g of polyacrylonitrile (organic polymer resin) and added it to 9.2g of DMF, and stirred for 4 hours until completely dissolved to form an 8% resin solution. Add 1.0 g of Na to the resin solution 3 V 2 (PO 4 ) 3 (electrode material), stirred for 12 hours, then ultrasonicated for 3 hours, and then stirred for 24 hours to obtain a uniformly dispersed mixed solution. Spread the mixed solution on a glass plate, volatilize for 5 minutes, set the thickness of the film to 100 μm, and then quickly immerse it in 5L of ethanol for 10 minutes to solidify to form a porous composite film. The composite film was pre-calcined at 300 °C for 3 h in an air atmosphere, and then calcined at 800 °C for 4 h in an argon atmosphere to obtain a 30 μm thick Na 3 V 2 (PO 4 ) 3 @3DPC-1 self-supporting electrode. The prepared Na 3 V 2 (PO 4 ) 3 @3DPC-1 Self-supporting electrode as wor...

Embodiment 2

[0040] Embodiment 2: (preparation Na 3 V 2 (PO 4 ) 3 @3DPC-2 self-supporting electrode)

[0041] Weighed 0.8g of polyacrylonitrile (organic polymer resin) and added it to 9.2g of DMF, and stirred for 6 hours until completely dissolved to form an 8% resin solution. Add 0.1 g of Na to the resin solution 3 V 2 (PO 4 ) 3 (electrode material), stirred for 12 hours, then ultrasonicated for 3 hours, and then stirred for 24 hours to obtain a uniformly dispersed mixed solution. Spread the mixed solution on a glass plate, volatilize for 5 minutes, set the thickness of the film to 100 μm, and then quickly immerse it in 5L of ethanol for 10 minutes to solidify to form a porous composite film. The composite film was pre-calcined at 300 °C for 3 h in an air atmosphere, and then calcined at 800 °C for 4 h in an argon atmosphere to obtain a 30 μm thick Na 3 V 2 (PO 4 ) 3 @3DPC-2 self-supporting electrodes. The battery assembly is the same as in Example 1.

Embodiment 3

[0042] Embodiment 3: (preparation Na 3 V 2 (PO 4 ) 3 @3DPC-3 self-supporting electrode)

[0043] Weighed 0.8 g of polyacrylonitrile (organic polymer resin) and added it to 9.2 g of DMF, and stirred for 7 hours until completely dissolved to form an 8% resin solution. Add 1.0 g of Na to the resin solution 3 V 2 (PO 4 ) 3 (electrode material), stirred for 12 hours, then ultrasonicated for 3 hours, and then stirred for 24 hours to obtain a uniformly dispersed mixed solution. Spread the mixed solution on a glass plate, volatilize for 30 minutes, set the thickness of the film to 100 μm, and then quickly immerse it in 5L of ethanol for 10 minutes to solidify to form a porous composite film. The composite film was pre-calcined at 300 °C for 3 h in an air atmosphere, and then calcined at 800 °C for 4 h in an argon atmosphere to obtain a 30 μm thick Na 3 V 2 (PO 4 ) 3 @3DPC-3 self-supporting electrodes. The battery assembly is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com