Harvesting and processing equipment for synthetic forage grass

A processing equipment and forage technology, which is applied in the field of synthetic forage harvesting and processing equipment, can solve problems such as restricting the sustainable development of animal husbandry, low protein content in straw, and unreasonable industrial layout, so as to improve and enhance the quality of roughage, promote the improvement, The effect of improving comprehensive quality and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

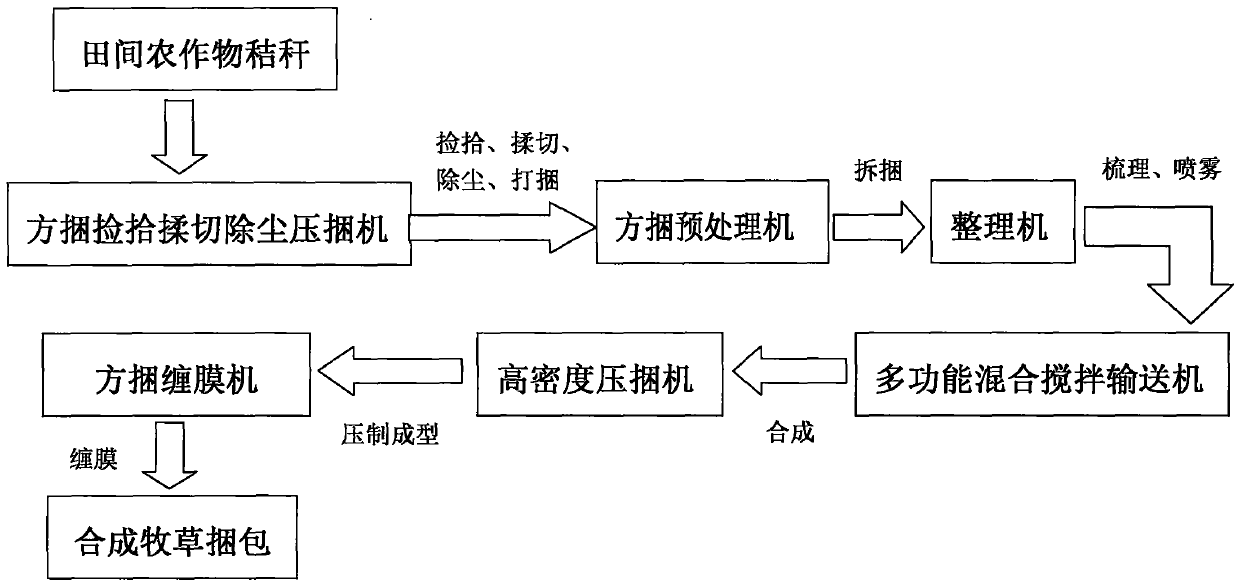

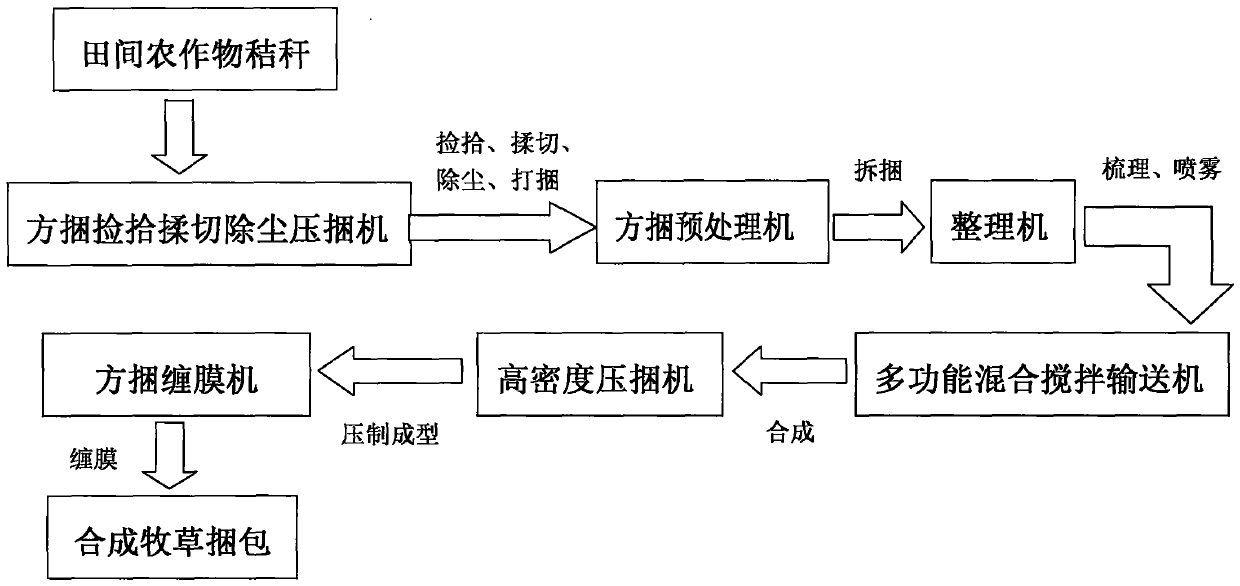

[0017] Synthetic forage harvesting and processing equipment conducts research on how to solve the problems of low nutrition and poor palatability of crop straw.

[0018] 1. The crop straw in the field is picked up, kneaded, dust-removed and baled by the square baler, and the corn, wheat, rice and other crop straws are picked up, kneaded and cut, dust-removed, and bundled to prepare for the next process.

[0019] 2. Put the crop straw bales prepared in the previous process into the square bale pretreatment machine, unbundle and break up the straw bales.

[0020] 3. The loose bales of straw enter the sorting machine for combing and spraying.

[0021] 4. Convey into the multifunctional mixing and stirring conveyor, spray natural additives such as protein powder for feed, and then stir evenly, and send it to the entrance of the compression chamber of the high-density baler.

[0022] 5. Press it into high-density bales of synthetic pasture through a high-density baler.

[0023] 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com