A kind of preparation method of iodine dressing

An iodine element and microcapsule technology, which is applied in pharmaceutical formulations, bandages, microcapsules, etc., can solve problems such as improving the irritation of iodine-containing dressings, increasing solvent consumption, and unfavorable compliance, and achieving improved hydrophilicity and competitive advantages. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

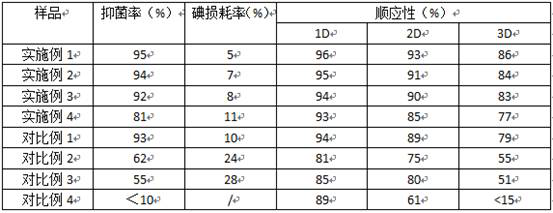

Examples

Embodiment 1

[0027] A preparation method of iodine-containing dressing, said preparation method comprising the following steps:

[0028] (1) Preparation of iodine microcapsules:

[0029] Pre-grind the iodine element into powder particles with a particle size of 1 μm, and then add the above raw materials according to the mass ratio of polyethylene glycol 1000: polyethylene glycol 800: glycerol: iodine particles at a ratio of 55:40:8:5, and heat at 35°C Stir and disperse evenly under the environment of 20°C to obtain iodine microcapsules;

[0030] (2) Preparation of iodine adhesive:

[0031] The mass ratio of the iodine adhesive is 20 parts of isooctyl acrylate; 2 parts of hydroxyethyl acrylate; 5 parts of vinyl acetate; 8 parts of acrylic acid; 34 parts of ethyl acetate; 32 parts of ethanol; 1 part of iodine microcapsules;

[0032] After stirring evenly, import it into the reaction kettle and pass it into the nitrogen protection. The flow rate of the nitrogen gas should be controlled at 1...

Embodiment 2

[0039] A preparation method of iodine-containing dressing, said preparation method comprising the following steps:

[0040] (1) Preparation of iodine microcapsules:

[0041] Pre-grind the elemental iodine into powder particles with a particle size of 3 μm, and then add the above raw materials according to the mass ratio of polyethylene glycol 1000: polyethylene glycol 800: glycerol: iodine particles at a ratio of 60:35:9:8, and heat at 35 °C Stir and disperse evenly under the environment of 20°C to obtain iodine microcapsules;

[0042] (2) Preparation of iodine adhesive:

[0043] The mass ratio of the iodine adhesive is 25 parts of isooctyl acrylate; 1 part of hydroxyethyl acrylate; 3 parts of vinyl acetate; 5 parts of acrylic acid; 40 parts of ethyl acetate; 25 parts of ethanol; 1.5 parts of iodine microcapsules;

[0044] After stirring evenly, import it into the reaction kettle and pass it into the nitrogen protection. The flow rate of the nitrogen gas should be controlled...

Embodiment 3

[0051] A preparation method of iodine-containing dressing, said preparation method comprising the following steps:

[0052] (1) Preparation of iodine microcapsules:

[0053] Pre-grind the iodine element into powder particles with a particle size of 5 μm, and then add the above raw materials according to the mass ratio of polyethylene glycol 1000: polyethylene glycol 800: glycerol: iodine particles in a ratio of 70:30:10:10. Stir and disperse evenly under the environment of 20°C to obtain iodine microcapsules;

[0054] (2) Preparation of iodine adhesive:

[0055] The mass ratio of the iodine adhesive is 30 parts of isooctyl acrylate; 0.5 parts of hydroxyethyl acrylate; 2 parts of vinyl acetate; 1 part of acrylic acid; 48 parts of ethyl acetate; 18 parts of ethanol; 2 parts of iodine microcapsules;

[0056] After stirring evenly, import into the reactor, and pass into nitrogen protection, the flow rate of nitrogen should be controlled at 165L / h; turn on the stirrer in the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com