Ultra-large interlayer spacing molybdenum disulfide/carbon composite material and preparation method of molybdenum disulfide/carbon composite material

A carbon composite material, molybdenum disulfide technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of poor electrical conductivity, affecting performance, unable to meet the requirements of high-performance catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

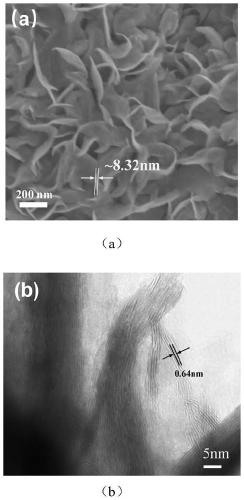

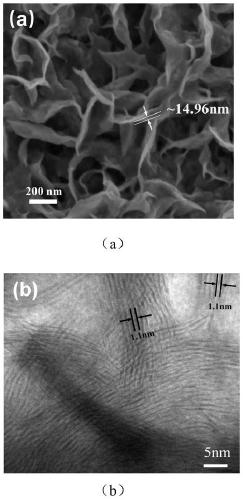

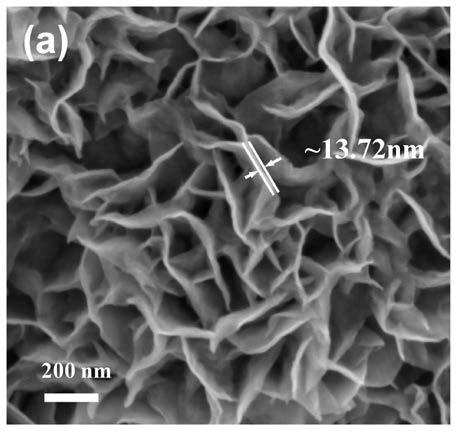

[0034] The present invention uses a two-step hydrothermal method to prepare dodecylamine-intercalated MoS with large interlayer spacing 2 sheets, MoS under nitrogen atmosphere 2 The complex with dodecylamine is annealed. During the annealing process, dodecylamine is converted into carbon in situ, and finally the MoS 2 While forming carbon particles between the sheets, the MoS 2 layer spacing. Super large interlayer spacing MoS in the present invention 2 The preparation method of / C composite material, comprises the following steps:

[0035] (1) Select sodium molybdate dihydrate and thiourea as reactants, fully mix and evenly disperse the mixed solution, use the autoclave as the container, and use the mixed solution as the reactant to prepare MoS by hydrothermal method 2 solution.

[0036] Mix sodium molybdate dihydrate and thiourea according to a molar ratio of 1:5, add the mixture to deionized water to obtain a mixed solution, and the mixed solution is obtained by stirri...

Embodiment 1

[0047] Add sodium molybdate dihydrate and thiourea with a molar ratio of 1:5 to deionized water, stir evenly and ultrasonically disperse to obtain a mixed solution. The mixed solution is subjected to a hydrothermal reaction at 210°C for 24 hours. After cooling, it is obtained Reaction product MoS 2 solution; the MoS 2 The solution was washed by centrifugation at 6000r / min for 3 times with acetone solution, 8min each time; 3 times with 8000r / min in deionized water, 6min each time; 3 times with 6000r / min in absolute ethanol, Wash for 8 minutes each time; obtain the mixed solution after cleaning, and dry the mixed solution after cleaning at 70°C for 14 hours to obtain MoS 2 powder; in MoS 2 Add 0.1% of its mass dodecylamine to the powder to obtain a mixed powder, dissolve the mixed powder in deionized water to obtain a mixed solution, and hydrothermally react the mixed solution at 80° C. for 8 hours to obtain a liquid reaction product; The product is cleaned and dried, and the...

Embodiment 2

[0049] Add sodium molybdate dihydrate and thiourea with a molar ratio of 1:5 to deionized water, stir evenly and ultrasonically disperse to obtain a mixed solution. The mixed solution is subjected to a hydrothermal reaction at 210°C for 24 hours. After cooling, it is obtained Reaction product MoS 2 solution; the MoS 2 The solution was washed by centrifugation at 8000r / min for 3 times with acetone solution, 6min each time; 3 times with 10000r / min in deionized water, 5min each time; 3 times with 8000r / min in absolute ethanol, Wash for 7 minutes each time; obtain the mixed solution after washing, and dry the mixed solution after washing at 90°C for 10 hours to obtain MoS 2 powder; in MoS 2 Add 0.1% of its mass dodecylamine to the powder to obtain a mixed powder, dissolve the mixed powder in deionized water to obtain a mixed solution, and hydrothermally react the mixed solution at 100° C. for 8 hours to obtain a liquid reaction product; The product is cleaned and dried, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com