Nitrogen-doped layered carbon catalyst for catalyzing the oxidation of ethylbenzene and its preparation method

A technology of nitrogen doping and layered carbon, which is applied in the direction of catalyst activation/preparation, oxidative preparation of carbonyl compounds, physical/chemical process catalysts, etc. It can solve the problems of unfriendly post-processing, skeleton collapse environment, and low natural abundance. Achieve the effects of easy scale-up production and preparation, superior catalytic performance, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the nitrogen-doped layered carbon catalyst used to catalyze the oxidation of ethylbenzene in this embodiment comprises the following steps:

[0028] In step 1, 0.2 g of phthalocyanine and 0.2 g of dicyandiamide were physically ground and mixed uniformly.

[0029] Step 2, placing the mixture of phthalocyanine and dicyandiamine obtained in step 1 in the middle of the quartz boat, and then placing it in the constant temperature interval of the tube furnace;

[0030] Step 3, continuously feed nitrogen into the tube furnace to purge the mixture of phthalocyanine and dicyandiamide, the nitrogen flow rate is 50mL / min, and the temperature of the tube furnace body is raised to 600 at a rate of 2°C / min. ℃ and kept for 1 hour, and then cooled to room temperature to obtain a nitrogen-doped layered carbon catalyst.

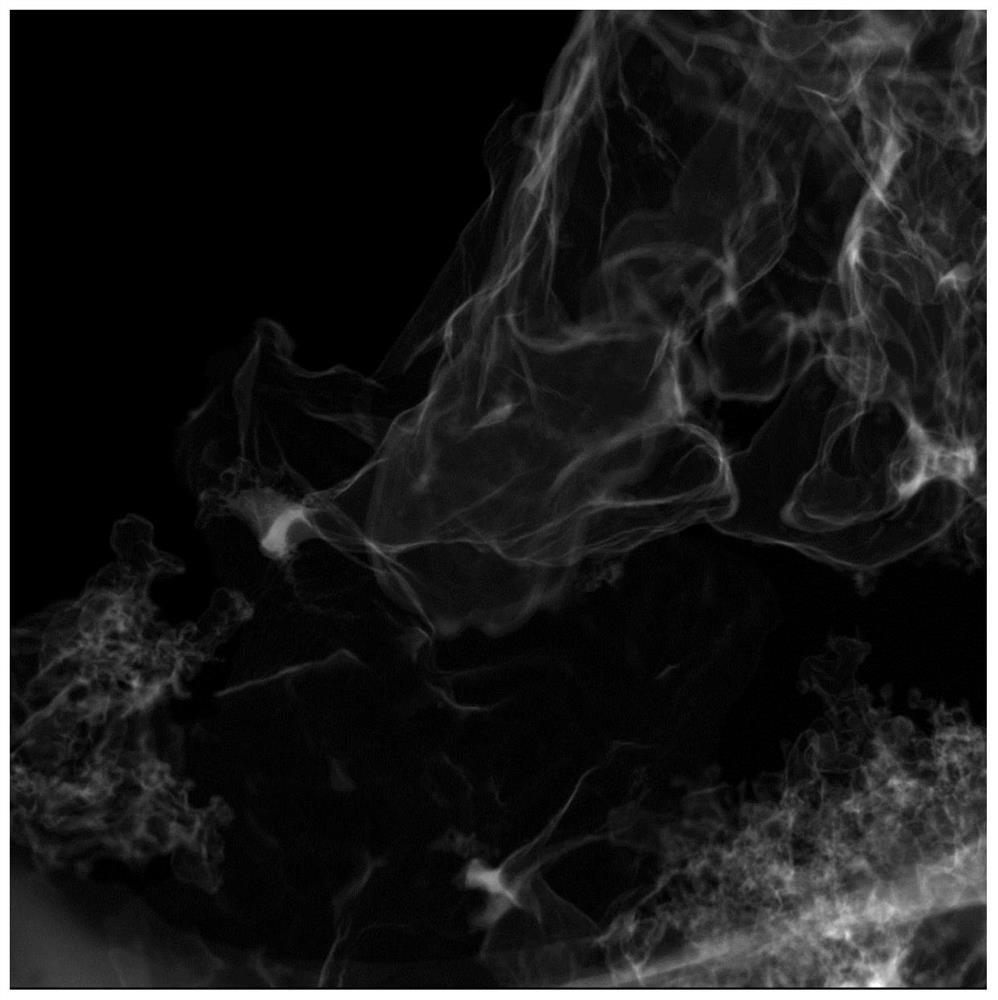

[0031] The specific surface area of the nitrogen-doped layered carbon catalyst used to catalyze the oxidation of ethylbenzene in this examp...

Embodiment 2

[0033] The preparation method of the nitrogen-doped layered carbon catalyst used to catalyze the oxidation of ethylbenzene in this embodiment comprises the following steps:

[0034] In step 1, 0.2 g of phthalocyanine and 1.0 g of dicyandiamide were physically ground and mixed uniformly.

[0035] Step 2, placing the mixture of phthalocyanine and dicyandiamide obtained in step 1 in the middle of the quartz boat, and then placing it in the constant temperature interval of the tube furnace;

[0036] Step 3, continuously feed nitrogen into the tube furnace to purge the mixture of phthalocyanine and dicyandiamide, the nitrogen flow rate is 100mL / min, and the temperature of the tube furnace body is raised to 700 at a heating rate of 3°C / min ℃ and kept for 2 hours, and then cooled to room temperature to obtain a nitrogen-doped layered carbon catalyst.

[0037] The specific surface area of the nitrogen-doped layered carbon catalyst used to catalyze the oxidation of ethylbenzene in t...

Embodiment 3

[0039] The preparation method of the nitrogen-doped layered carbon catalyst used to catalyze the oxidation of ethylbenzene in this embodiment comprises the following steps:

[0040] In step 1, 0.2 g of phthalocyanine and 2.0 g of dicyandiamide were physically ground and mixed uniformly.

[0041] Step 2, placing the mixture of phthalocyanine and dicyandiamide obtained in step 1 in the middle of the quartz boat, and then placing it in the constant temperature interval of the tube furnace;

[0042] Step 3, continuously feed nitrogen into the tube furnace to purge the mixture of phthalocyanine and dicyandiamide, the nitrogen flow rate is 200mL / min, and the temperature of the tube furnace body is raised to 800 at a heating rate of 5°C / min ℃ and kept for 4 hours, and then cooled to room temperature to obtain a nitrogen-doped layered carbon catalyst.

[0043] The specific surface area of the nitrogen-doped layered carbon catalyst used to catalyze the oxidation of ethylbenzene in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com