A ceramic/polytetrafluoroethylene composite dielectric substrate and its preparation method

A polytetrafluoroethylene and ceramic technology, used in the field of composite dielectric substrates, can solve the problems of unevenness, non-leveling, high dispersibility, stability and rheological requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

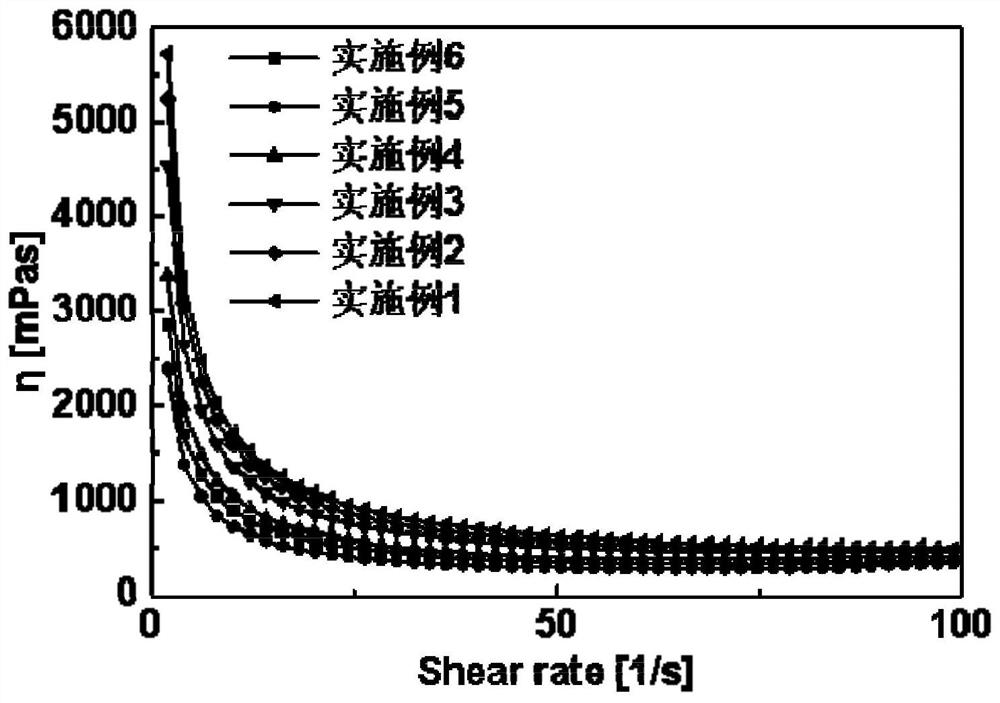

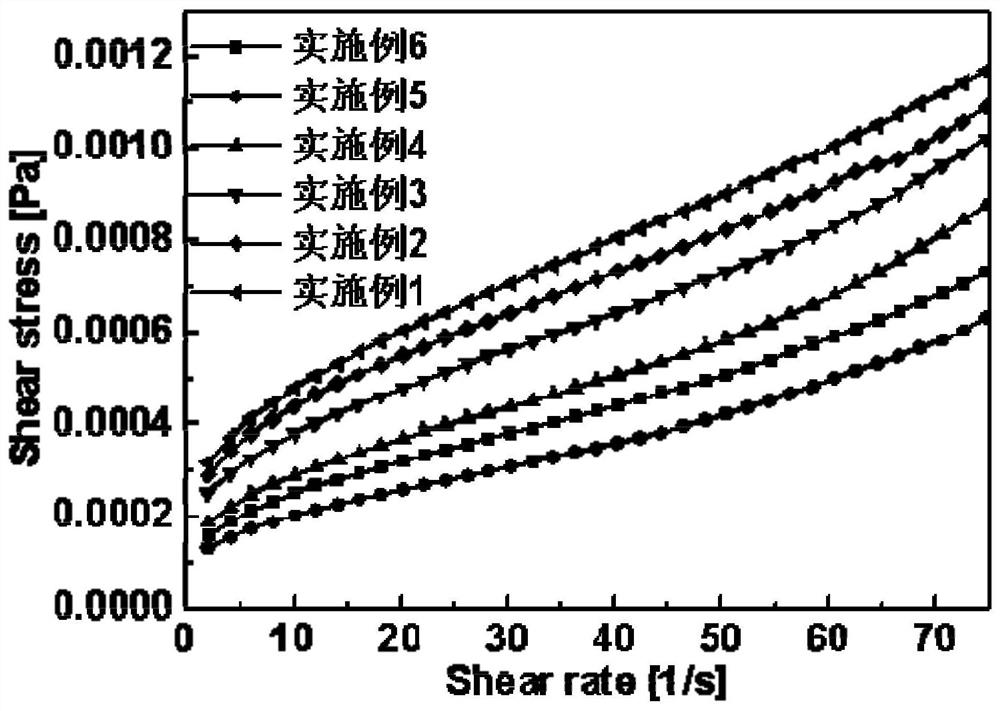

Embodiment 1

[0041] The silicon dioxide powder was uniformly mixed with 60wt% polytetrafluoroethylene emulsion (brand SFN-2H) at a ratio of 35:101.7 parts by weight. Then add 4 parts by weight of additive polyvinyl alcohol to adjust the viscosity of the slurry to the range of 500mPa·s-1500mPa·s. Adjust the height of the scraper to 2mm, cast the slurry on a glass fiber cloth substrate with a thickness of 0.04mm at a speed of 15cm / min, put it in an oven for drying, and use a gradient temperature rise program to discharge the additives and other impurities in the casting sheet. Then cool to room temperature. The specific gradient temperature program is: keep at 80°C for 2h, keep at 180°C for 2h, keep at 260°C for 4h, and keep at 330°C for 4h. Cut the cooled sheet, and use a hot press to perform double-sided copper-clad hot pressing in a vacuum high-temperature and high-pressure environment, where the pressure is 18MPa, the holding time is 1h, and the thickness of the copper foil is 35μm to o...

Embodiment 2

[0043] A ceramic / polytetrafluoroethylene composite dielectric substrate was prepared according to the method of Example 1, except that the weight ratio of silicon dioxide powder, polytetrafluoroethylene emulsion and polyvinyl alcohol was 30:110:4.

Embodiment 3

[0045] A ceramic / polytetrafluoroethylene composite dielectric substrate was prepared according to the method of Example 1, except that the weight ratio of silicon dioxide powder, polytetrafluoroethylene emulsion and polyvinyl alcohol was 25:118.3:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com