Bamboo charcoal anti-formaldehyde interior wall putty powder and preparation method thereof

An interior wall putty powder, anti-formaldehyde technology, applied in the direction of filling slurry, etc., can solve the problems of bamboo charcoal unable to decompose formaldehyde, secondary pollution, etc., and achieve the effect of improving the purification effect of formaldehyde, the stable molecular structure, and the fast and efficient adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

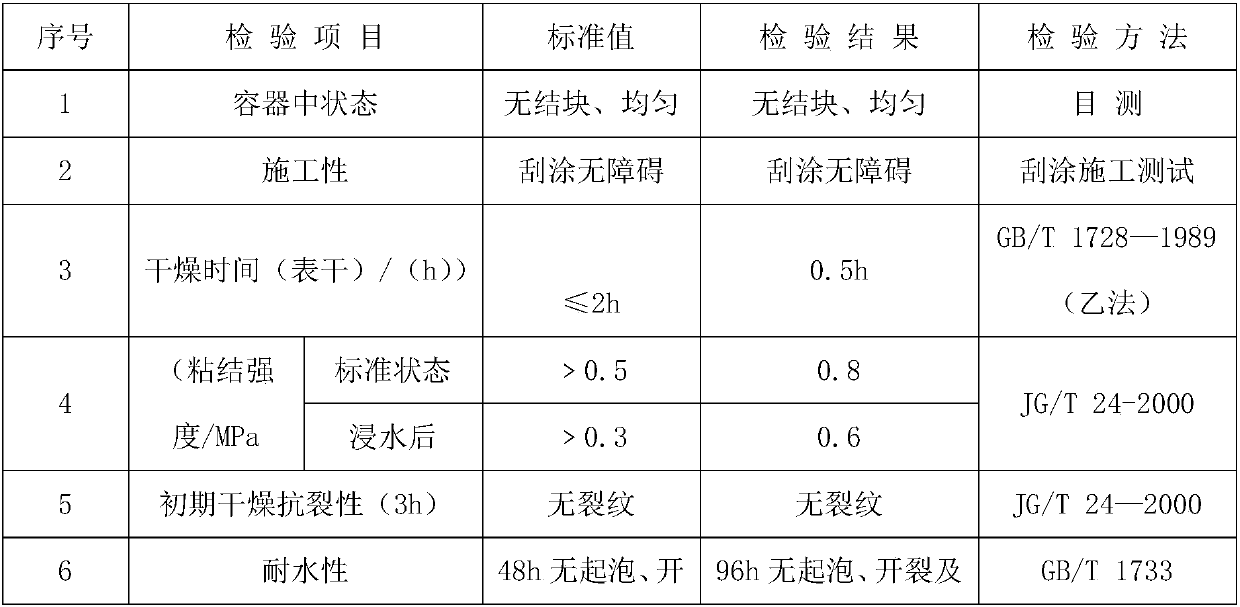

Embodiment 1

[0027] The bamboo charcoal anti-formaldehyde interior wall putty powder described in the present embodiment, by mass percent, is made up of following components: heavy calcium carbonate powder 54wt%, ash calcium powder 20wt%, white cement 20wt%, bamboo charcoal powder 4%, anti-formaldehyde Formaldehyde air purifier 1.5wt%, hydroxypropyl methylcellulose 0.4wt%, ultramarine 0.1wt%.

[0028] The filling putty manufacturing method is:

[0029] According to the above ratio, a. According to the formula quantity, mix heavy calcium carbonate powder, gray calcium powder and white cement according to the order of feeding, and stir for 10 minutes to make dry powder 1;

[0030] b. According to the formula quantity, mix bamboo charcoal powder, formaldehyde-resistant air purifier, hydroxypropyl methylcellulose, and ultramarine blue according to the order of addition, and stir for 2 minutes to make dry powder 2.

[0031] c. Put dry powder 2 into dry powder 1 and stir well for 10 minutes to ...

Embodiment 2

[0033] The bamboo charcoal anti-formaldehyde interior wall putty powder described in the present embodiment, by mass percent, is made up of following components: heavy calcium carbonate powder 52wt%, ash calcium powder 25wt%, white cement 18wt%, bamboo charcoal powder 3wt%, anti-formaldehyde Formaldehyde air purifier 1.5wt%, hydroxypropyl methylcellulose 0.4wt%, ultramarine 0.1wt%.

[0034] The filling putty manufacturing method is:

[0035] According to the above ratio, a. According to the formula quantity, mix heavy calcium carbonate powder, gray calcium powder and white cement according to the order of feeding, and stir for 10 minutes to make dry powder 1;

[0036] b. According to the formula quantity, mix bamboo charcoal powder, formaldehyde-resistant air purifier, hydroxypropyl methylcellulose, and ultramarine blue according to the order of addition, and stir for 2 minutes to make dry powder 2.

[0037] c. Put dry powder 2 into dry powder 1 and stir well for 10 minutes t...

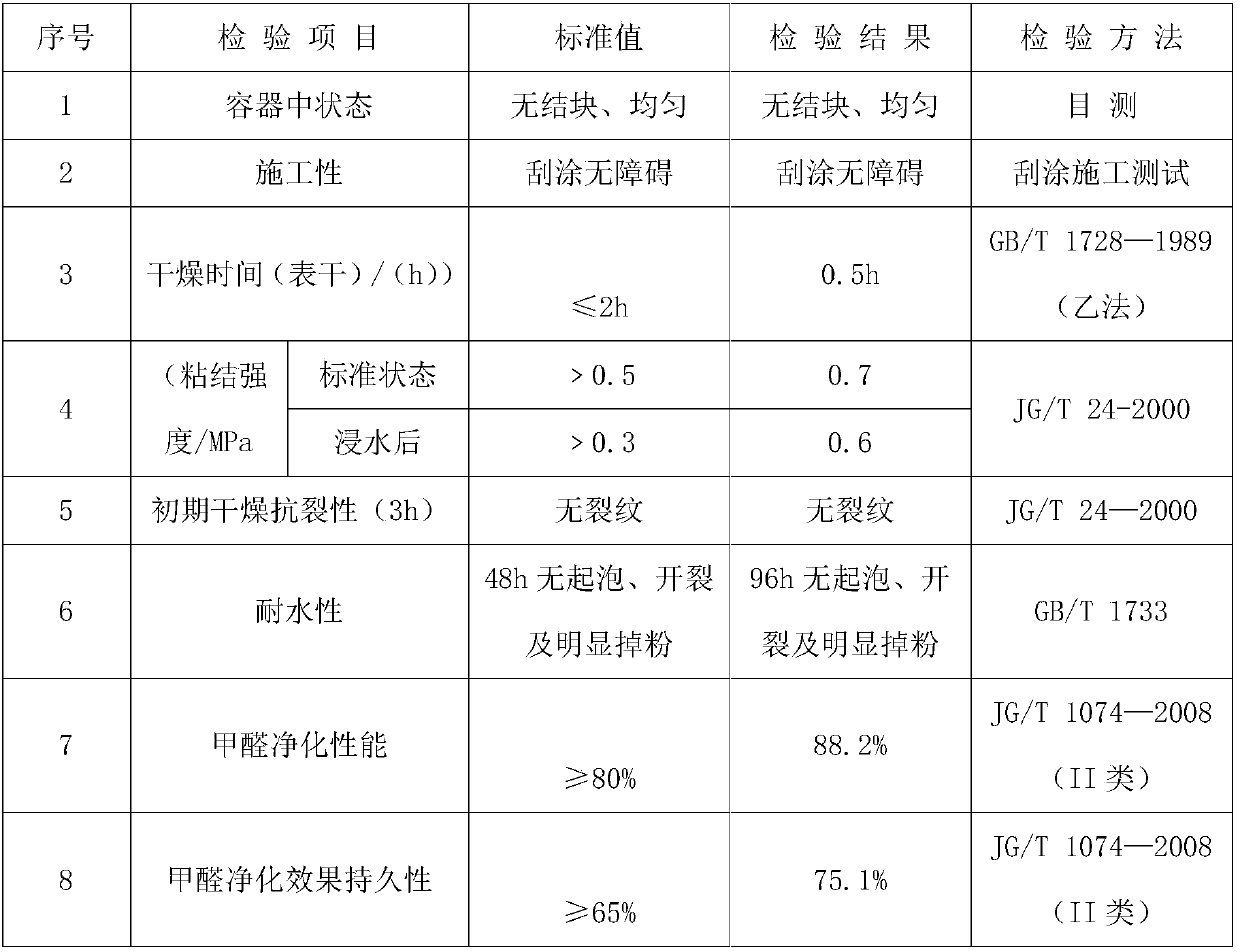

Embodiment 3

[0039] The bamboo charcoal anti-formaldehyde interior wall putty powder described in the present embodiment, by mass percent, is made up of following components: heavy calcium carbonate powder 40wt%, gray calcium powder 35wt%, white cement 19.5wt%, bamboo charcoal powder 4wt%, 1wt% anti-formaldehyde air purifier, 0.3wt% hydroxypropyl methylcellulose, 0.2wt% ultramarine.

[0040] The filling putty manufacturing method is:

[0041] According to the above ratio, a. According to the formula quantity, mix heavy calcium carbonate powder, gray calcium powder and white cement according to the order of feeding, and stir for 10 minutes to make dry powder 1;

[0042] b. According to the formula quantity, mix bamboo charcoal powder, formaldehyde-resistant air purifier, hydroxypropyl methylcellulose, and ultramarine according to the order of addition, and stir for 2 minutes to make dry powder 2.

[0043] c. Put dry powder 2 into dry powder 1 and stir well for 10 minutes to obtain bamboo c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com