Color paste for water-based ink and preparation method thereof

A color paste, hydrophilic monomer technology, applied in the field of coatings, can solve the problems of slow printing speed, unstable dispersion of disperse dyes, poor solvent affinity, etc., to improve stability, improve dispersibility and stability, and reduce surface energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: the preparation of dispersion agent (SA1)

[0067] (1) Mix 55g of methacrylic acid, 10g of acrylamide and 385g of o-phenylphenoxyethyl acrylate to obtain mixture a;

[0068] (2) Introduce nitrogen into the reaction flask with condensing reflux device, add 317g butanone and 163g isopropanol, heat to 70-80°C, then add 60g butanone and 10g azobisisoheptanonitrile and mix and stir To dissolve, obtain mixture b;

[0069] (3) Mix the mixture a and the mixture b, and slowly add it into the reaction bottle for reaction. At 70° C., after 7 hours of reaction, the amount of residual monomer is detected to be less than 5%, and the reaction is terminated to obtain a dispersant.

[0070] Add 2-pyrrolidone to the dispersant prepared in step (3) (the mass ratio of dispersant to 2-pyrrolidone is 1:0.54), heat to 100°C to remove the organic solvent in the dispersant, and then add deionized water, adjust the pH to 9 to obtain a dispersant solution, and the mass fraction of...

Embodiment 2

[0073] Embodiment 2: the preparation of dispersion agent (SA2)

[0074] (1) 330g H 2 C=CCH 3 CO 2 (CH 2 CH 2 O) n CH 3 n=50, 20g of N-vinylpyrrolidone and 100g of 2-phenoxyethyl acrylate were mixed to obtain mixture a;

[0075] (2) Introduce nitrogen into the reaction flask equipped with a condensing reflux device, add 344g of ethyl acetate and 164g of isopropanol as solvents, heat to 70-80°C, then add 36g of ethyl acetate and 6g of azobisisobutyl Nitriles are mixed and stirred until dissolved to obtain mixture b;

[0076] (3) Then mix the mixture a and the mixture b, and slowly add it into the reaction bottle for reaction at the same time. After 4 hours at 80° C., the residual monomer amount is detected to be less than 5% to stop the reaction and obtain a dispersant.

[0077] Add 2-pyrrolidone to the dispersant prepared in step (3) (the mass ratio of dispersant to 2-pyrrolidone is 1:0.544), heat to 100°C to remove the organic solvent in the dispersant, and then add d...

Embodiment 3

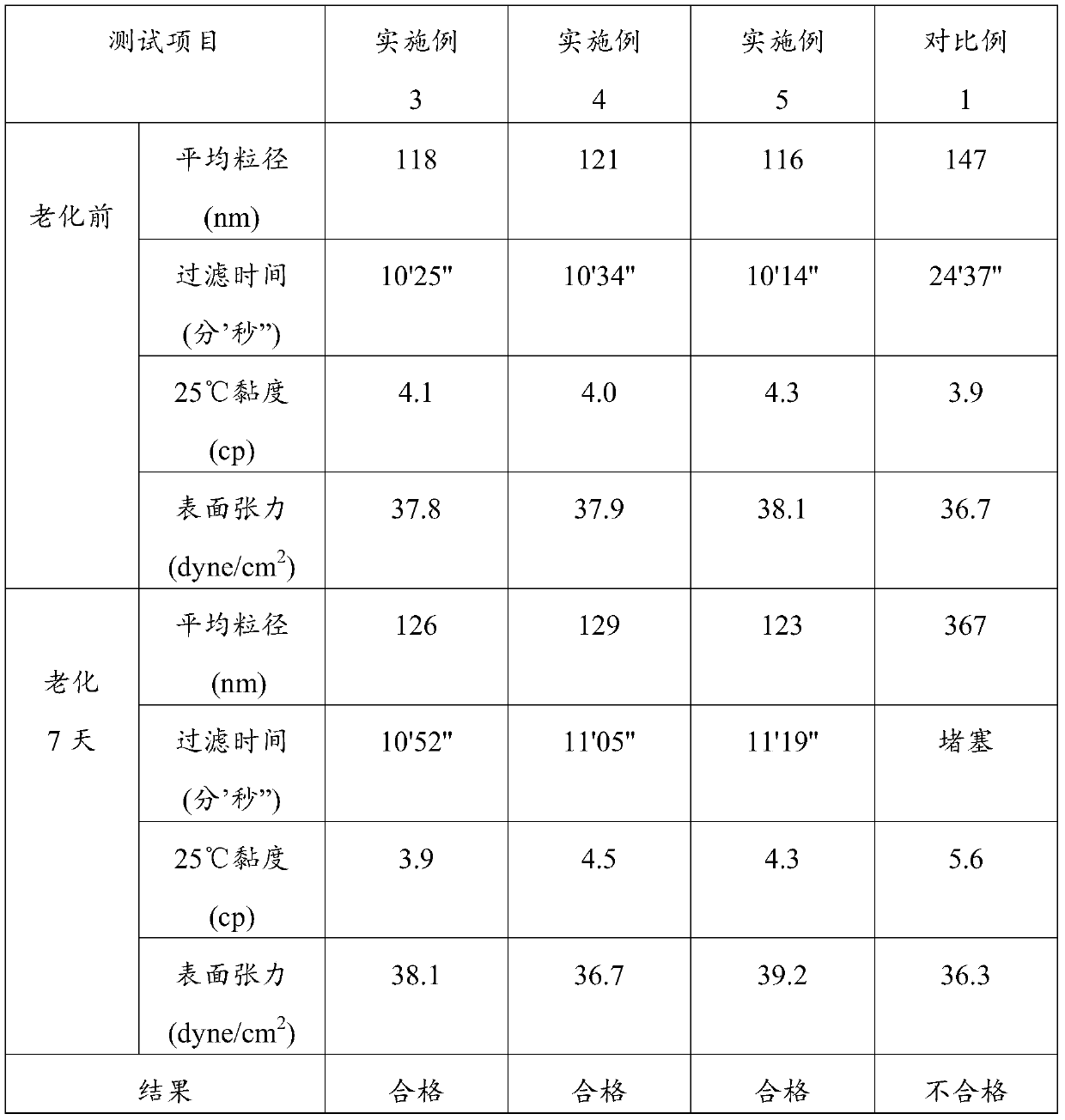

[0081] A preparation method of color paste, comprising the following steps:

[0082] (1) get the dispersant solution 508g that embodiment 1 makes and 1092g deionized water, stir and mix, make premixed solution;

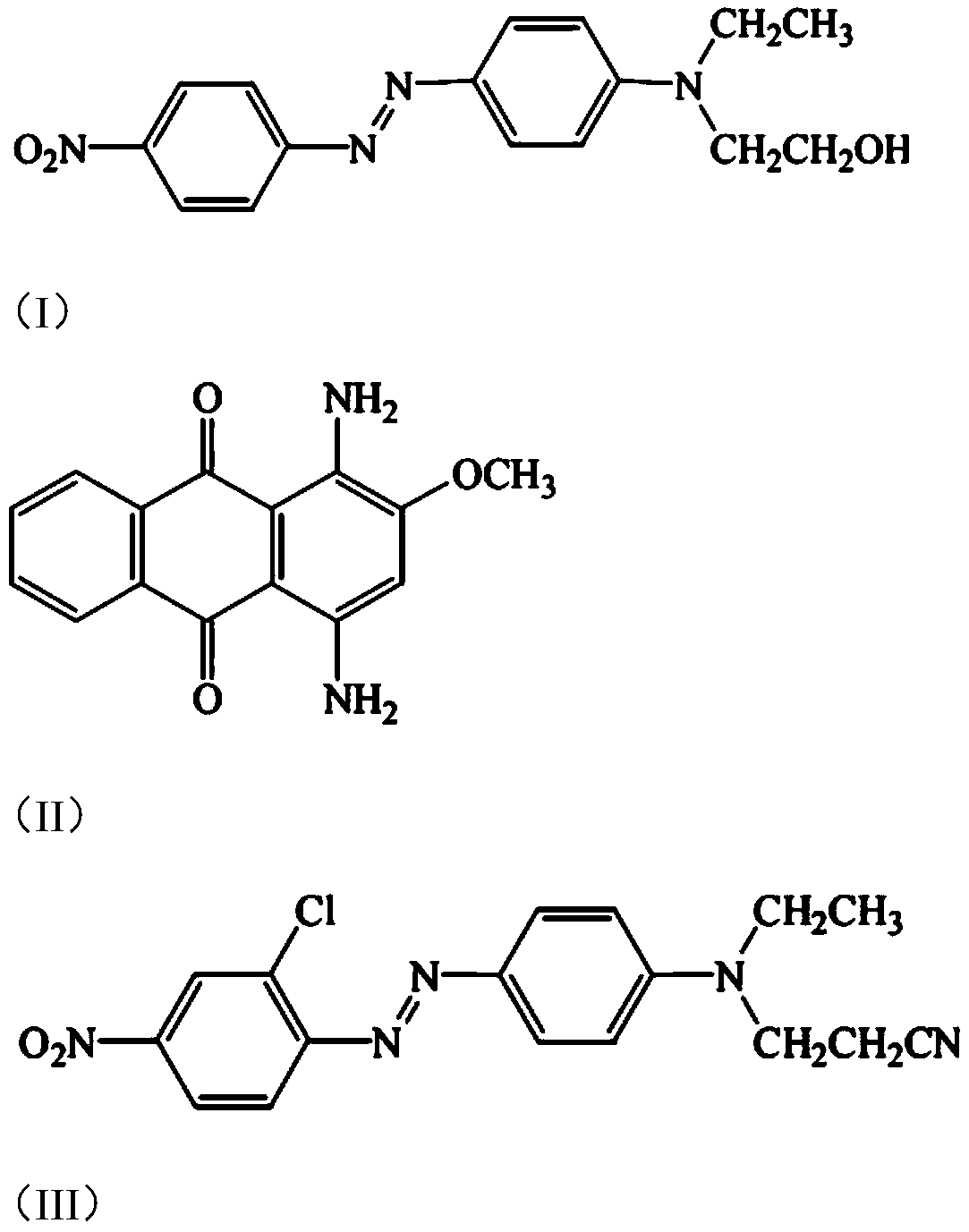

[0083] (2) 400g red disperse dye (III) is added in the premixed solution that step (1) prepares, stir and mix, import sand mill to grind then, the particle diameter of the premixed solution obtained by grinding is 100-200nm, filter, Take the filtrate to obtain the color paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com