Preparation method and application of nanocrystalline high-entropy oxide thin film

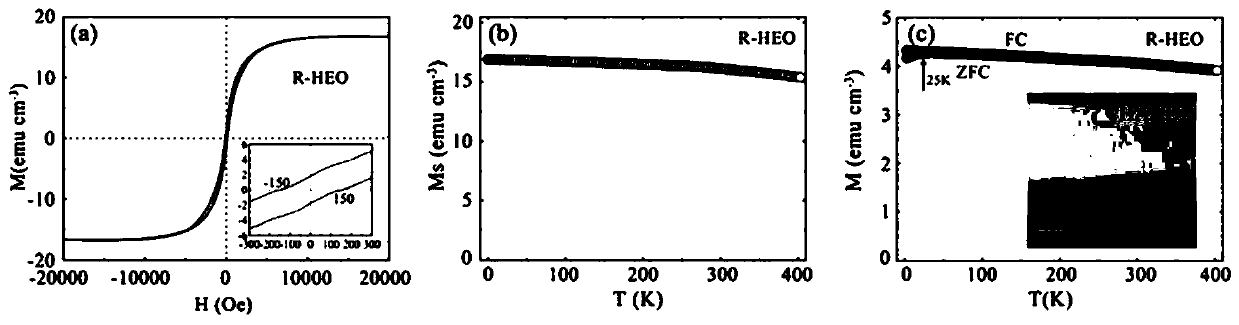

An oxide film and nanocrystalline technology, applied in ion implantation plating, metal material coating process, coating and other directions, to achieve the effect of large saturation magnetization, simple operation process and strong ferromagnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

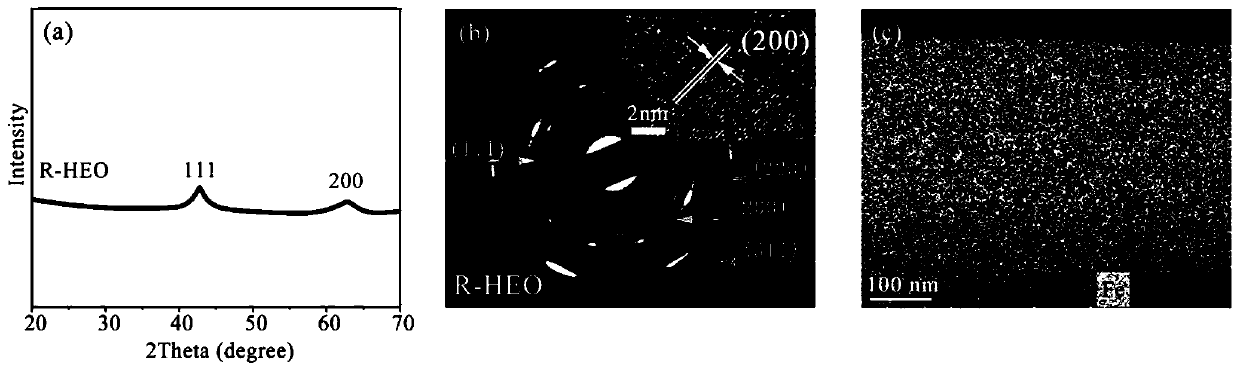

Examples

Embodiment 1

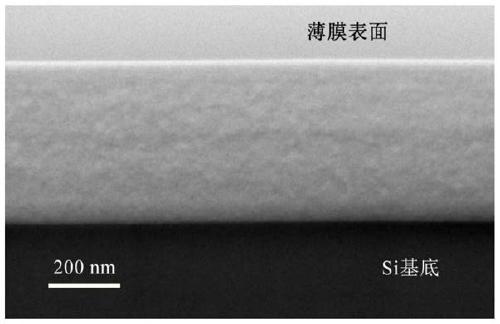

[0028] A method for preparing a nanocrystalline high-entropy oxide film, comprising the following steps:

[0029] Step S1: First weigh the metal oxide powder mixture with a purity higher than 99.90% and put it into the mold. The metal oxide powder mixture is composed of the following mass percentage: 14% Al 2 o 3 , 22%Cr 2 o 3 , 23% Fe 2 o 3 , 21% NiO and 20% MnO, and then cold-pressed it with a tablet press to make a cylindrical compact with a diameter of 50mm and a thickness of 5mm;

[0030] Step S2: Place the cylindrical compact in a muffle furnace for high-temperature calcination and then slowly cool to room temperature to obtain a mixed oxide target; the heating rate of the high-temperature calcination process is 1-10°C / min, and the calcination temperature is 1200-1500°C ℃, the constant temperature calcination time is 20-30 hours;

[0031] Step S3: ultrasonically clean the base material of monocrystalline silicon (100) with suitable size for 5 minutes with alcohol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com