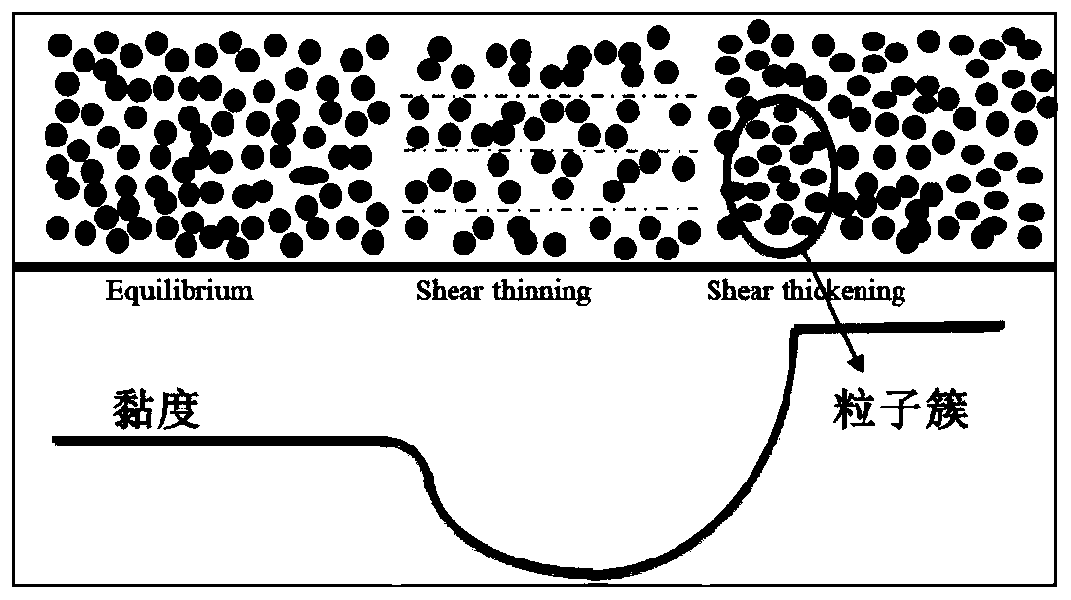

Shear thickening fluid based on ionic liquid and preparation method thereof

A technology of ionic liquid and thickening liquid, which is applied in the direction of textiles and papermaking, fiber treatment, fiber type, etc., can solve the problems of insignificant shear thickening effect and single function of STF, and achieve good shear thickening and easy The effect of simple operation and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

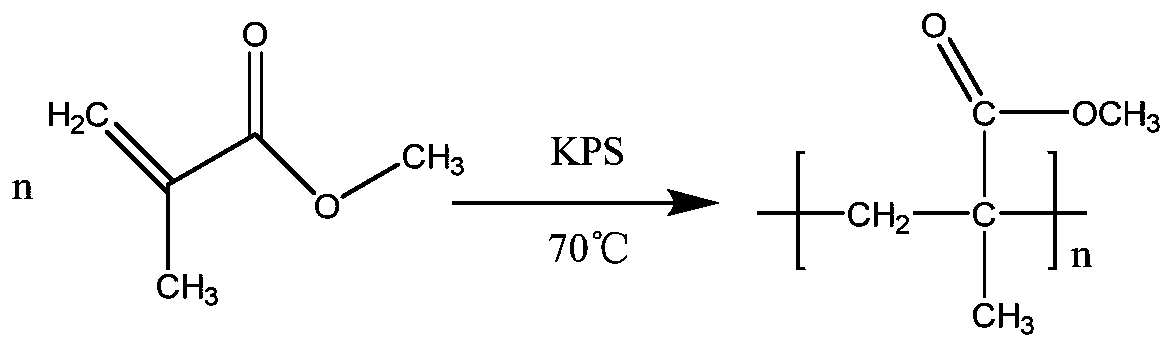

[0035] Preparation of polymethyl methacrylate (PMMA):

[0036] Take MMA and wash it three times with 5% NaOH solution, wash it with double distilled water to neutrality, add anhydrous calcium chloride to dry, and seal the monomer in a conical flask with a ground stopper, store it in the refrigerator and let it stand for 24 hours. Then take the upper layer of MMA for later use; add 0.05g NaCl, 10g of the above-mentioned treated MMA and 60ml of deionized water into a four-necked flask equipped with a condenser, a nitrogen gas conduit and a mechanical stirrer, and pass nitrogen gas under stirring at 300rpm to drive oxygen for 15min.

[0037] 30ml of an aqueous solution of potassium persulfate (KPS) (the amount of KPS is 0.2wt.% of the amount of methyl acrylate; 0.25wt.%; 0.3wt.%; 0.35wt.%; 0.4wt.%) was added to the flask , and then the temperature was raised to 70°C to start polymerization. After reacting for 4 hours, it was cooled to room temperature, and the polymer emulsion w...

Embodiment 2

[0044] The preparation of the shear thickening liquid of different concentrations comprises the following steps:

[0045] (1) Put the three-neck flask into the ultrasonic cleaner, clamp it on the constant speed stirrer, adjust the position, and ensure that the ultrasonic cleaning is supplemented by mechanical stirring.

[0046] (2) The dispersion medium [BMIM]PF 6 (Example 1) Pour into a three-necked flask, and in the process of stirring and ultrasonic oscillation, gradually add the particle diameter synthesized in Example 1 to be 0.13 μm PMMA particles, so that it is evenly dispersed in the dispersion medium as much as possible, and the concentration of the prepared polymer particles is respectively 2wt.%, 4wt.%, 6wt.%, 8wt.%, 10wt% STF.

[0047] (3) Ultrasonic stirring and dispersing for 1 h, and the prepared sample was placed in a vacuum drying oven for 24 h at a temperature of 30° C. to remove air bubbles in the STF and obtain a stable STF system.

[0048] (4) A rotation...

Embodiment 3

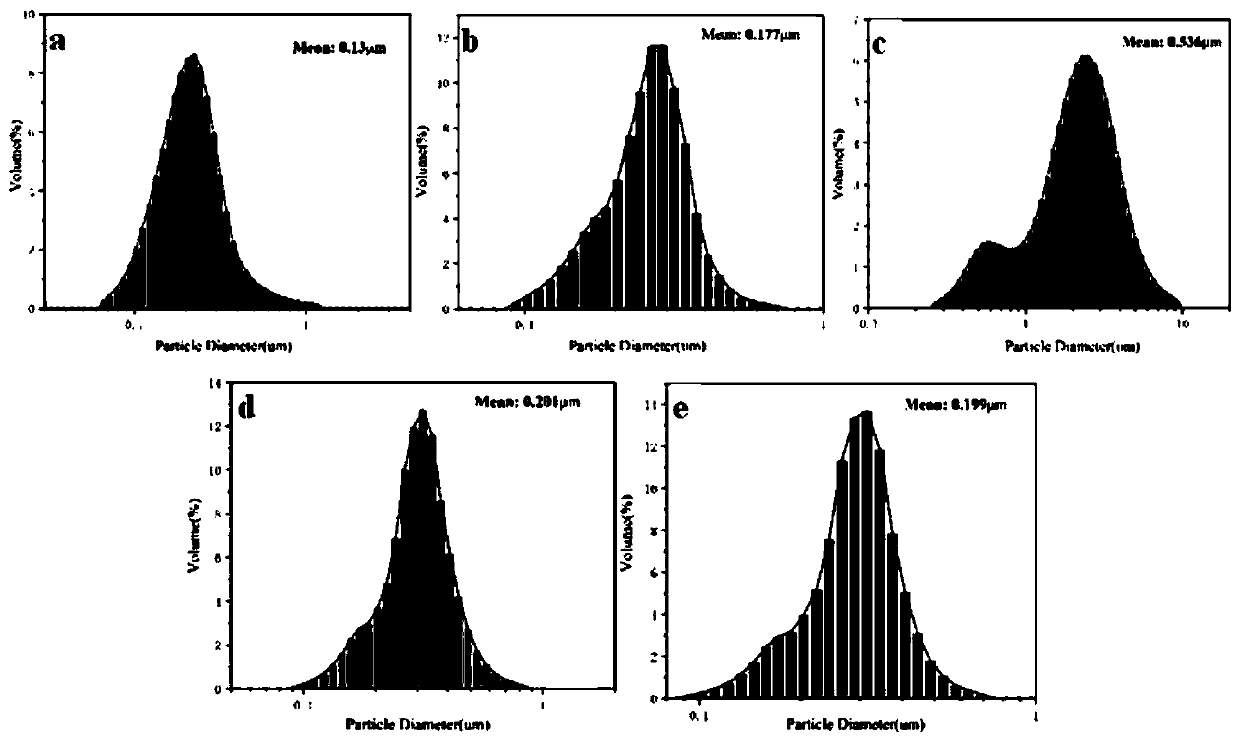

[0051] The preparation of the shear thickening liquid of different particle sizes comprises the following steps:

[0052] (1) As described in embodiment 2 step (1).

[0053] (2) as described in embodiment 2 step (2), adopt PMMA particles (obtained in embodiment 1) of five groups of different particle sizes of 0.13 μm, 0.17 μm, 0.19 μm, 0.20 μm and 0.53 μm to prepare 10wt.% STF .

[0054] (3) As described in embodiment 2 step (3).

[0055] (4) As described in embodiment 2 step (4).

[0056] Result: if Figure 7 As shown, under the same dispersed phase content, the STF critical shear viscosity increases from 300.8Pa with the increase of dispersed phase particle size . s gradually decreased to 7.2Pa . s, the critical shear rate is changed from 2s -1 Gradually rise to 11s -1 , the shear thickening behavior is weakened, and the shear thickening performance is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com