Copper smelting slag slow cooling system and slow cooling method

A copper smelting slag and slow cooling technology, which is applied in the direction of furnaces, furnace components, and discharged materials, can solve the problems of high grinding production cost, long cooling time, and large site area, and achieve easy crushing and grinding, Less pressure loss in the pipeline and the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

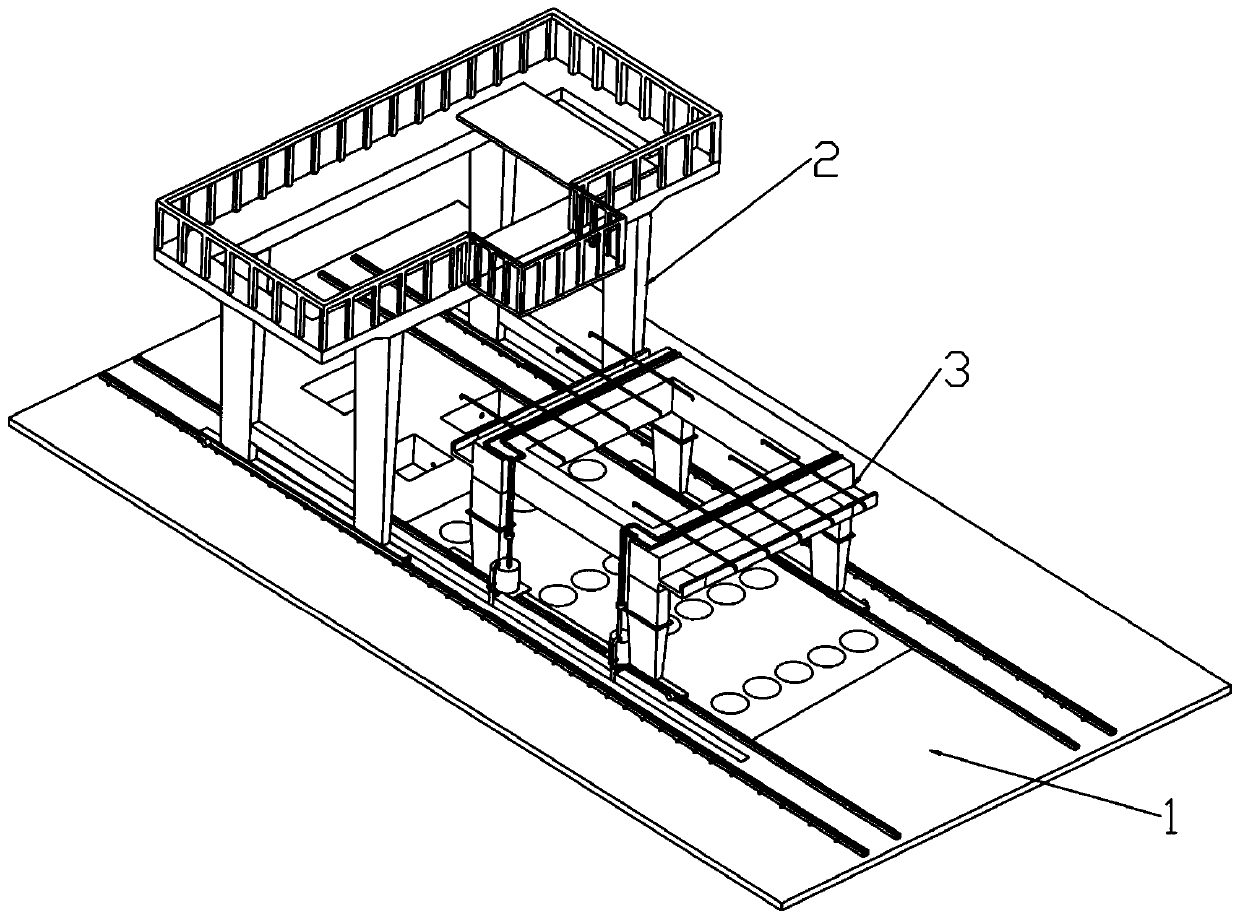

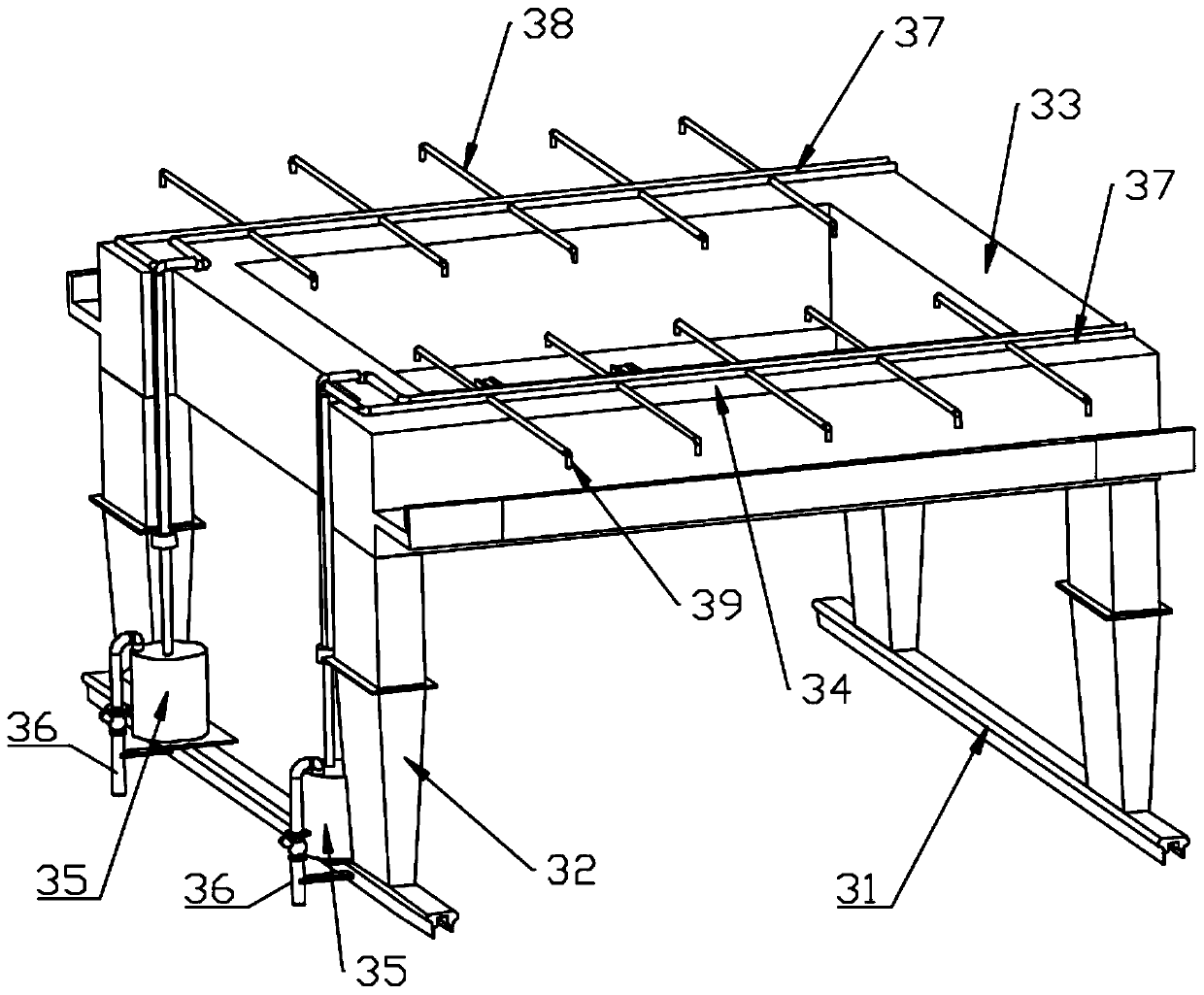

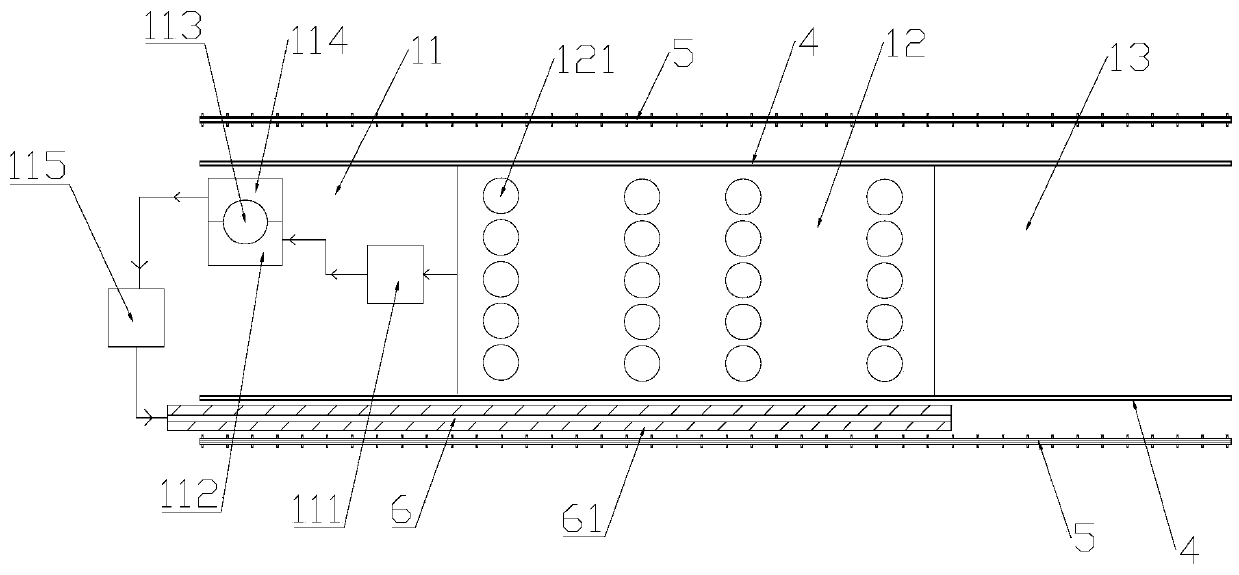

[0032] see figure 1 with image 3 , in a preferred embodiment of the present invention, a slow cooling system for copper smelting slag, comprising a slow cooling field 1 for slag, a gantry crane 2 and a sprinkler machine 3, the gantry crane 2 is used for changing and turning over the slag ladle operation, the sprinkler machine 3 is used to move and spray and cool the slag bag, and the number of the gantry crane 2 and the number of the sprinkler machine 3 are flexibly adjusted according to the actual slowly cooling slag package, that is, when the slow cooling When the amount of cold slag bag is large, multiple gantry cranes 2 and multiple sprinkler machines 3 can be operated simultaneously to improve the slow cooling efficiency of slag bag. The outside of the two long sides of the slag slow cooling field 1 is provided with a gantry crane track 5 and a sprinkler door machine track 4. The gantry crane track 5 is located outside the sprinkler door machine track 4. Machine tracks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com