Application of non-fullerene organic photovoltaic cells under indoor light

An organic photovoltaic cell, non-fullerene technology, applied in the field of non-fullerene photoelectric materials, can solve problems such as low photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

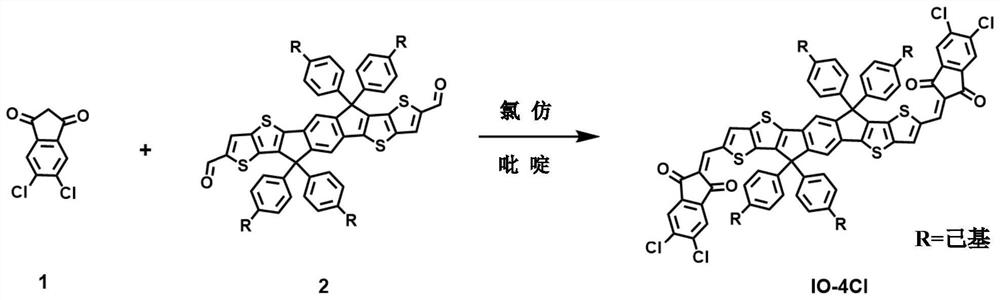

[0108] Example 1 Preparation of IO-4Cl Compound

[0109] Refer figure 2 The synthetic route, 199.1 mg of Compound 1 (purchased from Suli Organic Optoelectronics Technology (Beijing) Co., Ltd.) and 214.8mg Compound 2 (purchased from Suli Organic Optoelectronics Technology (Beijing) Co., Ltd.) added to 50ml round bottom flask. The air in the bottle is introduced into the bottle to carry out argon protection. A 20 mL of chloroform and 0.2 ml of pyridine were added. Then, the round bottom flask was moved into a 65 ° C oil bath to stir for 15 hours. After the reaction was completed, 208.6 mg of Compound IO-4Cl was purified by column.

[0110] m / z: [M + H] + 1469.

[0111] 1 H-NMR (CDCL 3 400MHz): δ (PPM), 8.43 (S, 2H), 7.99 (S, 4H), 7.92 (S, 2H), 7.64 (S, 2H), 7.22 (D, 8H), 7.15 (D, 8H) 2.57 (t, 8h), 1.59 (t, 8h), 1.31 (m, 24h), 0.86 (t, 12h).

[0112] 13 C-NMR (CDCL 3 ,400MHz):δ(ppm),187.94,187.19,155.36,151.82,147.28,145.25,143.77,142.47,140.70,139.65,139.53,139.33,139.16,139.01,13...

Embodiment 2

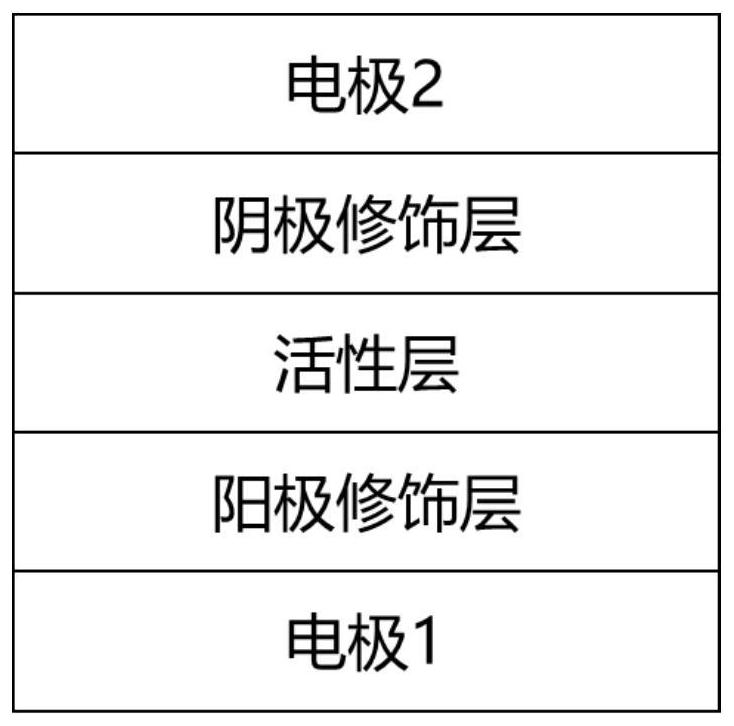

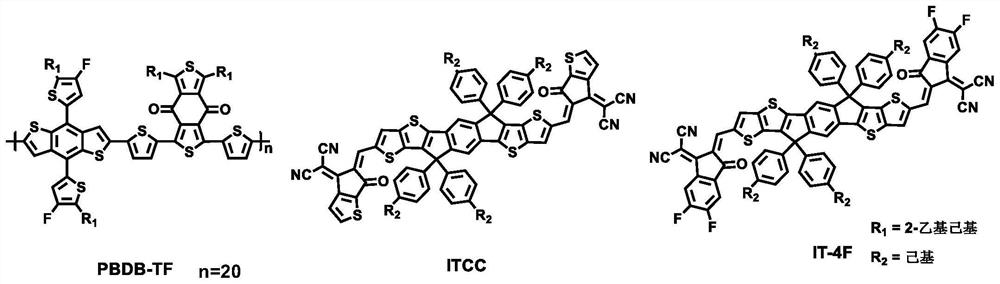

[0113] Example 2 A photovolus battery is prepared based on a PBDB-TF / ITCC system

[0114] PBDB-TF (from SOLAMERMETERIALINC Purchase) with ITCC (purchased from SOLAMERMETERIALIALINC) with a weight ratio of 1: 1 common mixed dissolved in chlorobenzene to prepare 10 mg / ml of blended activatable layer solution, then 0.5% by volume 1, 8 - iodine octane is prepared in the blended spiral solution. Device preparation is followed by: First, the commonly used anode modification layer PEDOT: PSS is spin coated on the surface of ITO, annealing at 150 ° C for 20 minutes. The substrate was then moved to the glove box, and the above blended activated layer solution was then copies into a membrane (2000 rmp / min, 90s) on the PEDOT: PSS layer. The film was then annealed at 100 ° C for 10 minutes. After the substrate is cooled, ZnO nanoparticles (dispersed in methanol solution) are spin on the active layer film. Finally, at approximately 10 -4 A 100 nm aluminum layer was evaporated under press...

Embodiment 3

[0117] Example 3 Preparation of photovoltaic cells based on PBDB-TF / IT-4F system

[0118]PBDB-TF (from SolamerMeterialInc Purchase) with IT-4F (purchased from SolamerMeterialInc) with a weight ratio of 1: 1 co-mixed in chlorobenzene, then prepared a total of 10 mg / ml of a blended lamination solution, and then 0.5% by volume ratio 1 8-biode octane is added to the blended spiral solution. Device preparation is followed by: First, the commonly used anode modification layer PEDOT: PSS is spin coated on the surface of ITO, annealing at 150 ° C for 20 minutes. The substrate was then moved to the glove box, and the above blended activated layer solution was then copies into a membrane (2000 rmp / min, 90s) on the PEDOT: PSS layer. The film was then annealed at 100 ° C for 10 minutes. After the substrate is cooled, ZnO nanoparticles (dispersed in methanol solution) are spin on the active layer film. Finally, at approximately 10 -4 A 100 nm aluminum layer was evaporated under pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com