Device and method for improving synchronous control accuracy of servo system of dual-axis direct drive platform

A servo system and synchronous control technology, applied in the field of numerical control, to improve the ability to process data, avoid high-frequency oscillations, and improve positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

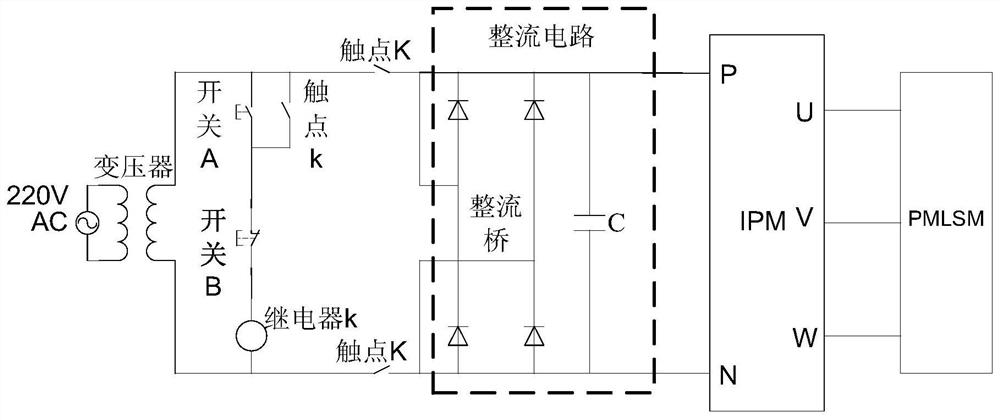

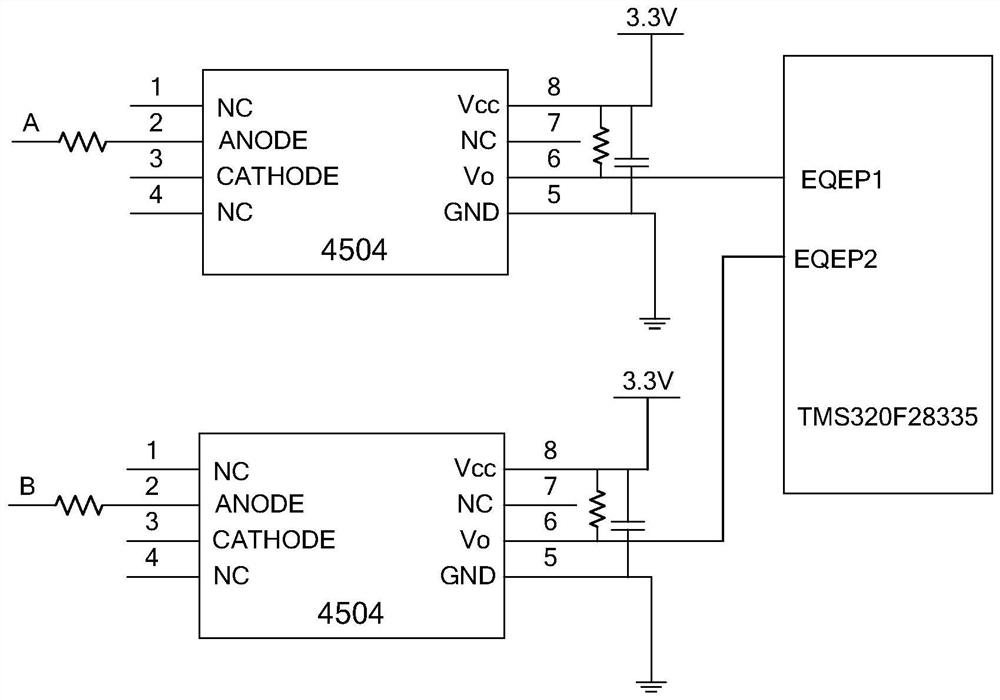

[0096] On the one hand, the present invention provides a device for improving the synchronous control accuracy of the dual-axis direct-drive platform servo system, such as figure 1 As shown, it includes a power supply module, a DSP processor module, a detection module, a first IPM isolation protection drive circuit, a second IPM isolation protection drive circuit, a dual-axis platform, and a host computer module;

[0097] The power module includes a three-phase AC power supply, a rectification circuit and an IPM inverter circuit; the rectification circuit is used as the input end of the entire control device to receive the signal of the final motion position of the permanent magnet linear synchronous motor given by the user, The input terminal of the rectifier circuit is connected to the three-phase AC power supply, which converts the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com