Catalytic cracking aid for improving heavy oil conversion capability, and preparation method thereof

A catalytic cracking aid and capability technology, applied in the field of catalytic cracking aid for improving heavy oil conversion capacity and its preparation field, can solve the problem of increasing gasoline octane number, unable to reduce gasoline olefin content, aid heavy oil conversion capacity and heavy metal resistance The pollution ability is not strong enough to achieve the effect of improving quality and improving the distribution of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

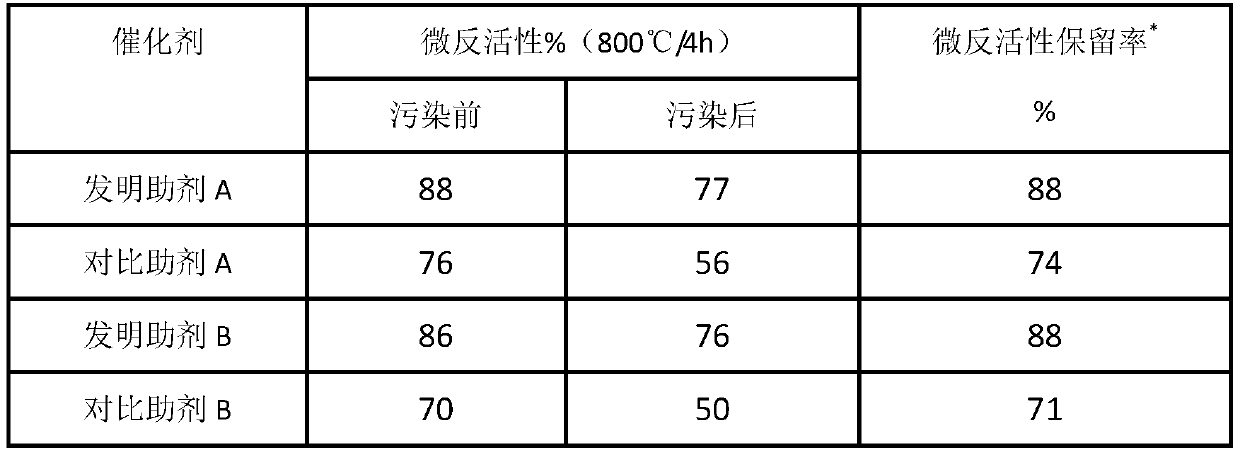

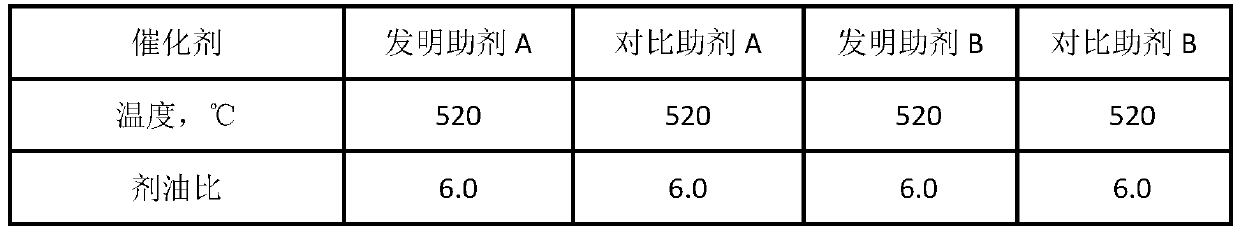

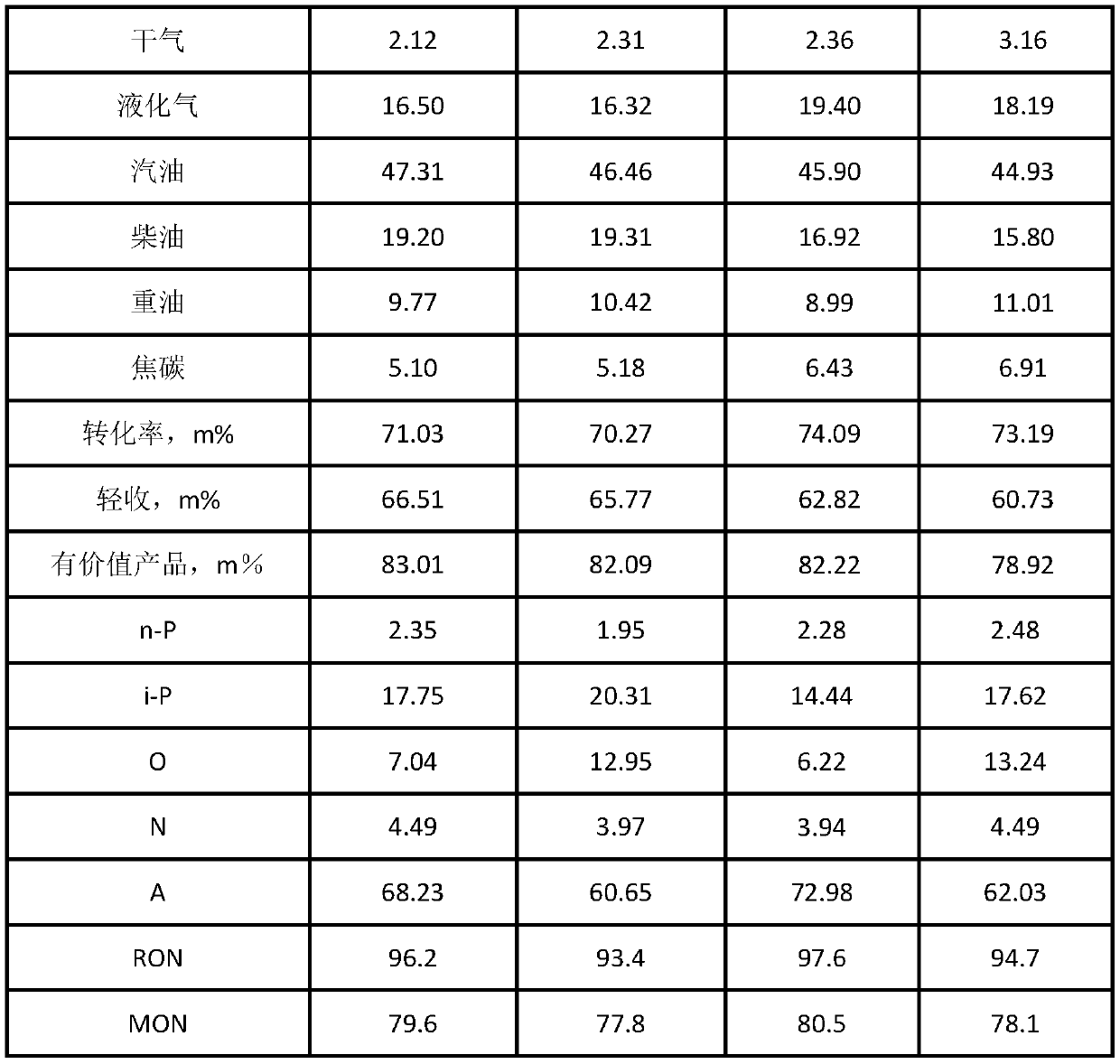

Examples

Embodiment 1

[0028]Add water to 3500g of sepiolite to make a slurry with a solid content of 33%, add 250ml of sodium silicate, spray and form it into microspheres, take 2000g of microspheres and roast them in a muffle furnace at 950°C for 4 hours to obtain roasted microspheres A; Add water to 3500g of kaolin to make a slurry with a solid content of 33%, add 250ml of sodium silicate, spray into microspheres, get 350g of microspheres and roast them in a muffle furnace at 820°C for 4 hours to obtain roasted microspheres B; In the state, 4000ml of sodium silicate, 500ml of lye, 760ml of zeolite directing agent, 1900g of roasted particle microspheres, and 330g of roasted particle microspheres were put into the stainless steel reactor in sequence, and the temperature was raised to 98°C for constant temperature crystallization for 30 hours. After the crystallization is completed, the mother liquor is removed by filtration, and the filter cake is washed and dried to obtain an intermediate product o...

Embodiment 2

[0032] Add 5000g of sepiolite with water to make a slurry with a solid content of 40%, add 250ml of sodium silicate, 70g of Tianqing powder, and 200g of ZSM-5 molecular sieve, spray and form it into granule microspheres, take 400g of granule microspheres and roast them in a muffle furnace at 1000°C After 2 hours, roasted microspheres C were obtained; under stirring, 200ml of sodium silicate, 150ml of lye, 60ml of molecular sieve guide agent, 15g of ZSM-5 molecular sieve, and 380g of roasted microspheres C were put into a stainless steel reactor, and the temperature was raised to 100°C , constant temperature crystallization for 26 hours. After the crystallization is completed, the mother liquor is removed by filtration, and the filter cake is washed and dried to obtain an intermediate product of in-situ crystallization. Measured by X-ray diffraction, it contains 40% NaY zeolite, the zeolite silicon-aluminum ratio (molar ratio) is 4.9, the wear index is 0.5, the specific surface...

Embodiment 3

[0036] Mix 2000g of sepiolite and 300g of roasted kaolin and add water to make a slurry with a solid content of 47%, add 60g of sodium carbonate, 50g of polyacrylamide, and 100g of NaY molecular sieve, and spray it into particle microspheres. Take 600g of particle microspheres in a muffle furnace at 880 ℃ roasting for 6 hours to obtain roasted microspheres D; in the state of stirring, 1200ml of sodium silicate, 100ml of lye, 180ml of molecular sieve guiding agent, and 580g of roasted microspheres D were put into a stainless steel reactor, and the temperature was raised to 100°C. Crystallize for 32 hours. After the crystallization is completed, the mother liquor is removed by filtration, and the filter cake is washed and dried to obtain an intermediate product of in-situ crystallization. Measured by X-ray diffraction, it contains 73% NaY zeolite, the zeolite silicon-alumina ratio (molar ratio) is 5.3, the wear index is 1.7, the specific surface area is 693m2 / g, and the pore vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com