Scale-like dense-tooth diamond coating milling cutter for composite material

A technology of diamond coating and composite material, applied in the direction of tools, milling cutters, milling machine equipment, etc. for milling machines, it can solve the problems of tool wear and processing quality, high milling force, poor thermal conductivity, etc., to increase the flow speed and enhance the hardness. , the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

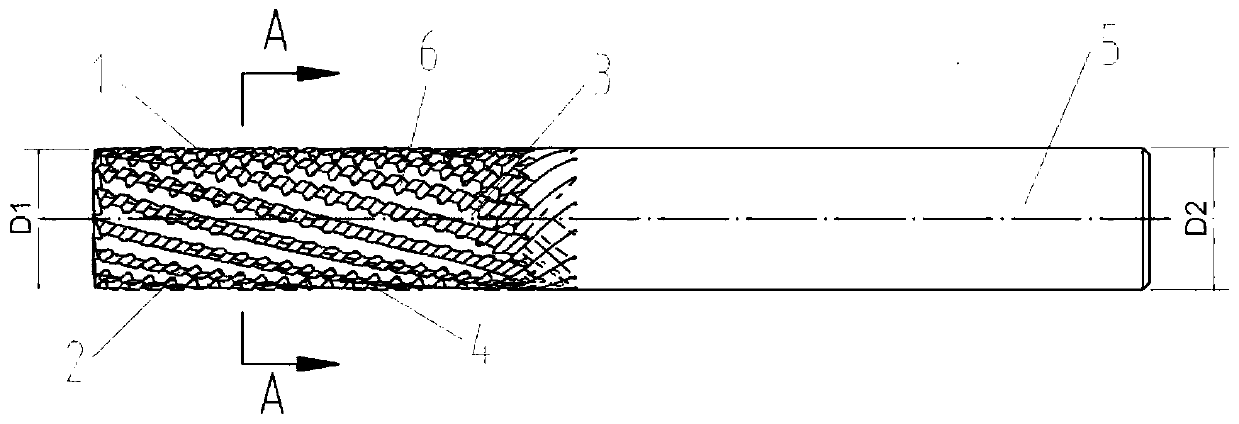

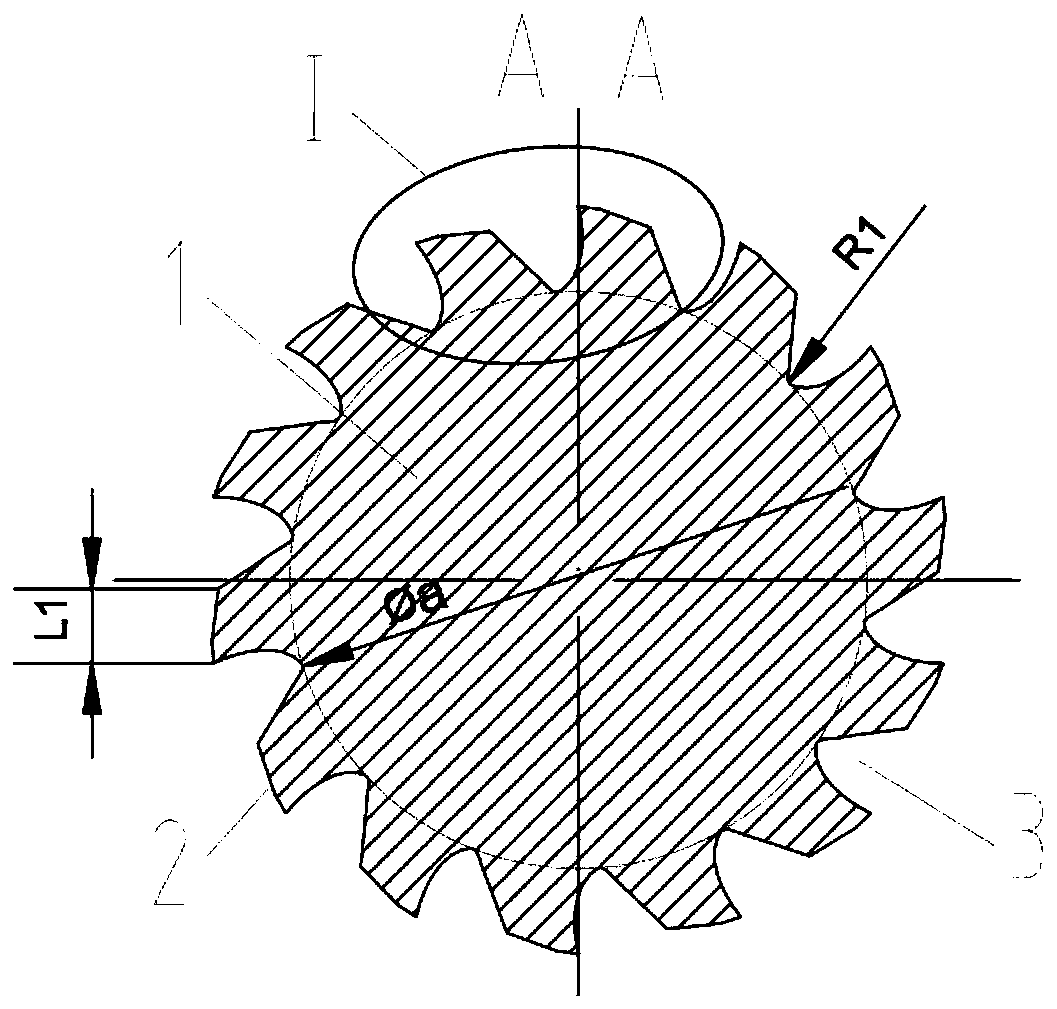

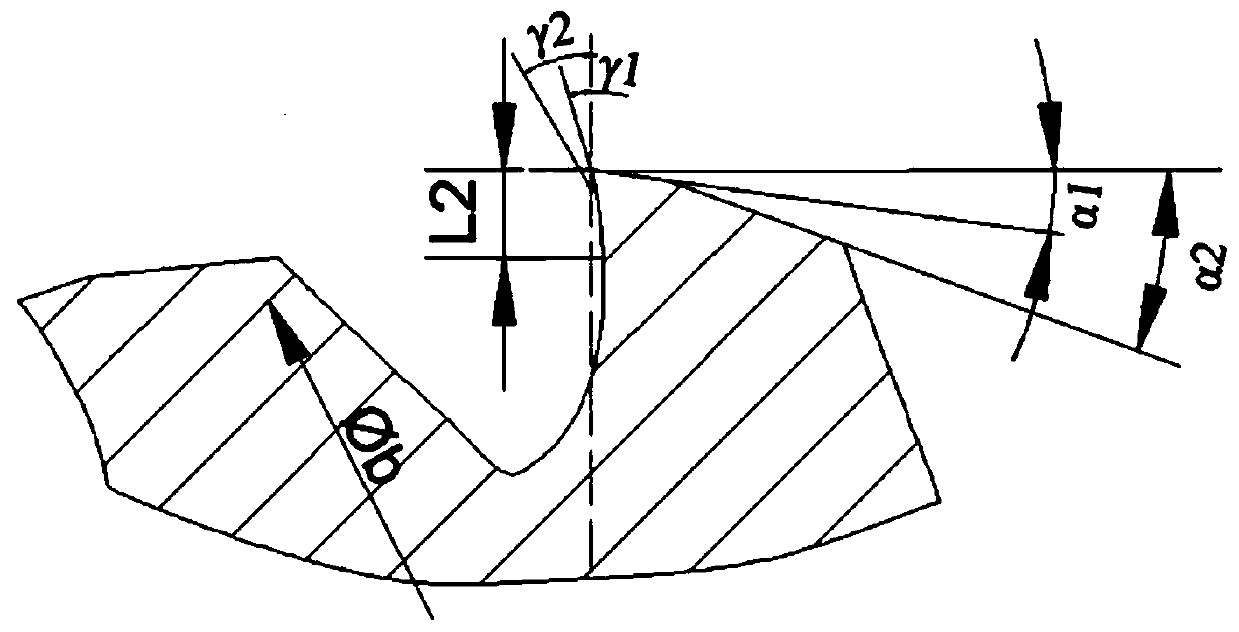

[0028] Such as Figure 1-7 As shown, a scale-shaped fine-tooth diamond-coated milling cutter for composite materials can be used for side machining of aerospace composite materials. The diameter of the cylinder where the shank 5 is located is D2, which is used for clamping and fixing the tool. The tool body 1 and the cylindrical shank 5 are coaxial cylinders centered on a common axis. The peripheral edges form right-handed right-handed helical flutes 3 along the circumferential direction, and the peripheral edge back 2 is formed on the cutter body 1 through the right-helical flutes 3, and the right-helical flutes 3 have a shallow groove structure The prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com