Black Ta2O5, and preparation method and application thereof

A ta2o5, black technology, applied in the field of photocatalysis, can solve the problems of complex process, high production cost, toxic and harmful, etc., and achieve the effect of simple preparation process and strong absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

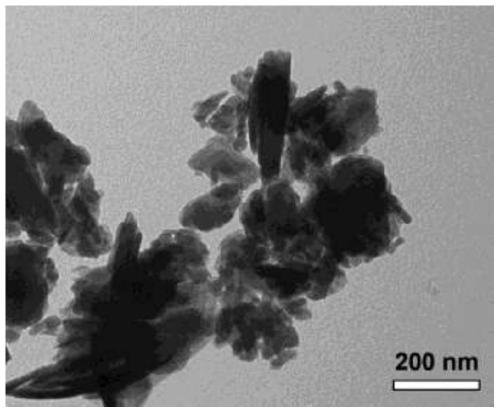

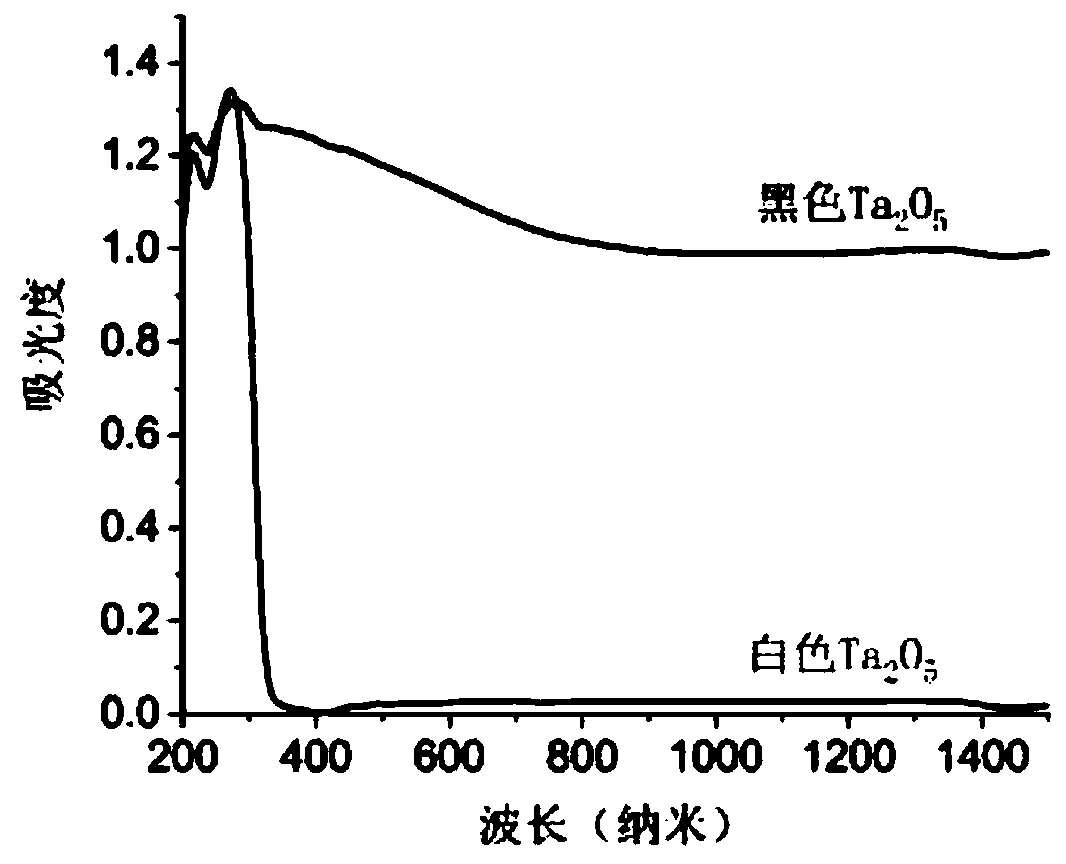

Image

Examples

Embodiment 1

[0044] A kind of black Ta 2 o 5 A preparation method comprising the steps of:

[0045] S1. Preparation of TaCl 5 Sol precursor

[0046] 3g TaCl 5 Dissolve in a glass beaker filled with 30mL of absolute ethanol, slowly add 5mL of acetylacetone stabilizer, stir magnetically for 3h to obtain TaCl 5 Sol precursor;

[0047] S2, preparation of tantalum oxide gel powder

[0048] TaCl 5 The sol precursor was aged in an oven at a temperature of 80°C. After the ethanol solvent was completely volatilized, the massive solid at the bottom of the beaker was taken out and transferred to a ball milling tank. The ball milling time was 24 hours to obtain tantalum oxide gel powder;

[0049] S3, prepared white Ta 2 o 5 powder

[0050] Put the tantalum oxide gel powder into a corundum crucible, place it in a muffle furnace, control the temperature rise rate to 10°C / min, heat it to 600°C, and keep it for 4 hours to obtain white Ta 2 o 5 powder;

[0051] S4, prepare black Ta 2 o 5 pow...

Embodiment 2

[0054] A kind of black Ta 2 o 5 A preparation method comprising the steps of:

[0055] S1. Preparation of TaCl 5 Sol precursor

[0056] 10g TaCl 5 Dissolve in a glass beaker filled with 30mL of absolute ethanol, slowly add 2mL of acetylacetone stabilizer, and stir magnetically for 6h to obtain TaCl 5 Sol precursor;

[0057] S2, preparation of tantalum oxide gel powder

[0058] TaCl 5 The sol precursor was aged in an oven at a temperature of 60°C. After the ethanol solvent was completely volatilized, the massive solid at the bottom of the beaker was taken out and transferred to a ball milling tank. The ball milling time was 48 hours to obtain tantalum oxide gel powder;

[0059] S3, prepared white Ta 2 o 5 powder

[0060] Put the tantalum oxide gel powder into a corundum crucible, place it in a muffle furnace, control the temperature rise rate at 5°C / min, heat it to 800°C, and keep it for 2 hours to obtain white Ta 2 o 5 powder;

[0061] S4, prepare black Ta 2 o 5...

Embodiment 3

[0064] A kind of black Ta 2 o 5 A preparation method comprising the steps of:

[0065] S1. Preparation of TaCl 5 Sol precursor

[0066] 6g TaCl 5 Dissolve in a glass beaker filled with 30mL of absolute ethanol, slowly add 4mL of acetylacetone stabilizer, and stir for 5h under magnetic force to obtain TaCl 5 Sol precursor;

[0067] S2, preparation of tantalum oxide gel powder

[0068] TaCl 5 The sol precursor was aged in an oven at a temperature of 70°C. After the ethanol solvent was completely volatilized, the massive solid at the bottom of the beaker was taken out and transferred to a ball milling tank. The ball milling time was 36 hours to obtain tantalum oxide gel powder;

[0069] S3, prepared white Ta 2 o 5 powder

[0070] Put the tantalum oxide gel powder into a corundum crucible, place it in a muffle furnace, control the temperature rise rate at 8°C / min, heat it to 700°C, and keep it for 3 hours to obtain white Ta 2 o 5 powder;

[0071] S4, prepare black Ta ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com