Multi-phase composite reinforced low-friction silicon carbide ceramic sealing material and preparation method thereof

A technology of friction silicon carbide and silicon carbide ceramics, which is applied in the field of low-friction silicon carbide ceramic sealing materials and its preparation, can solve the problems of less attention to the friction performance of composite materials, limited synergistic enhancement effect, and complicated hot-pressing sintering process, etc., to achieve Improve the mechanical properties and friction properties, improve the surface smoothness, improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

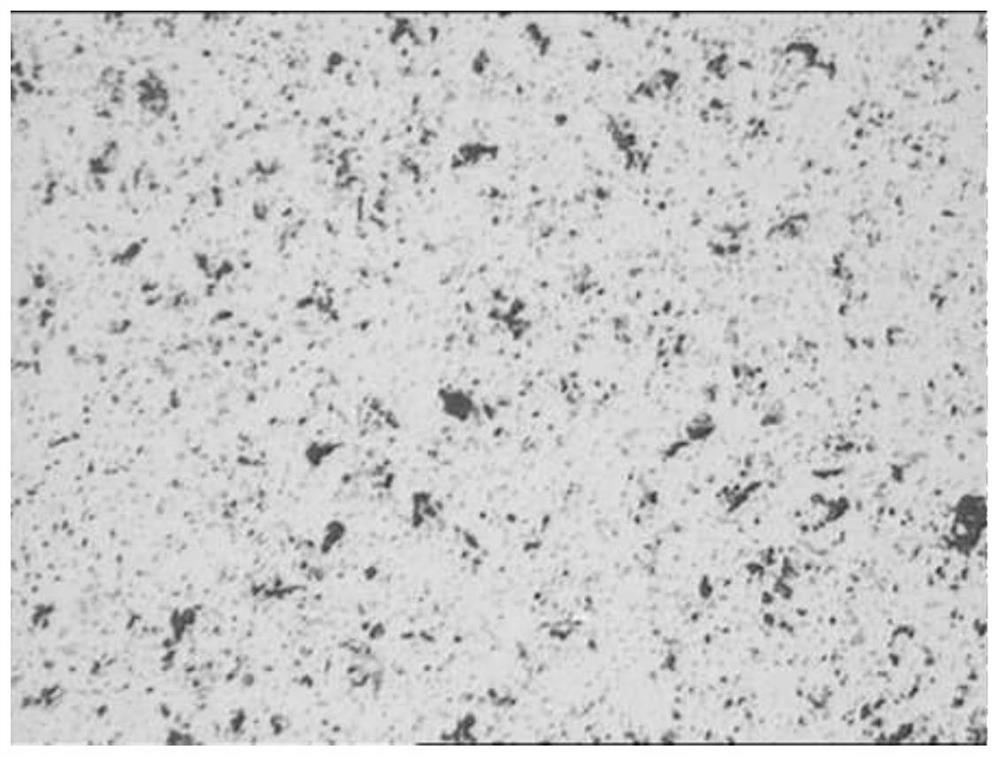

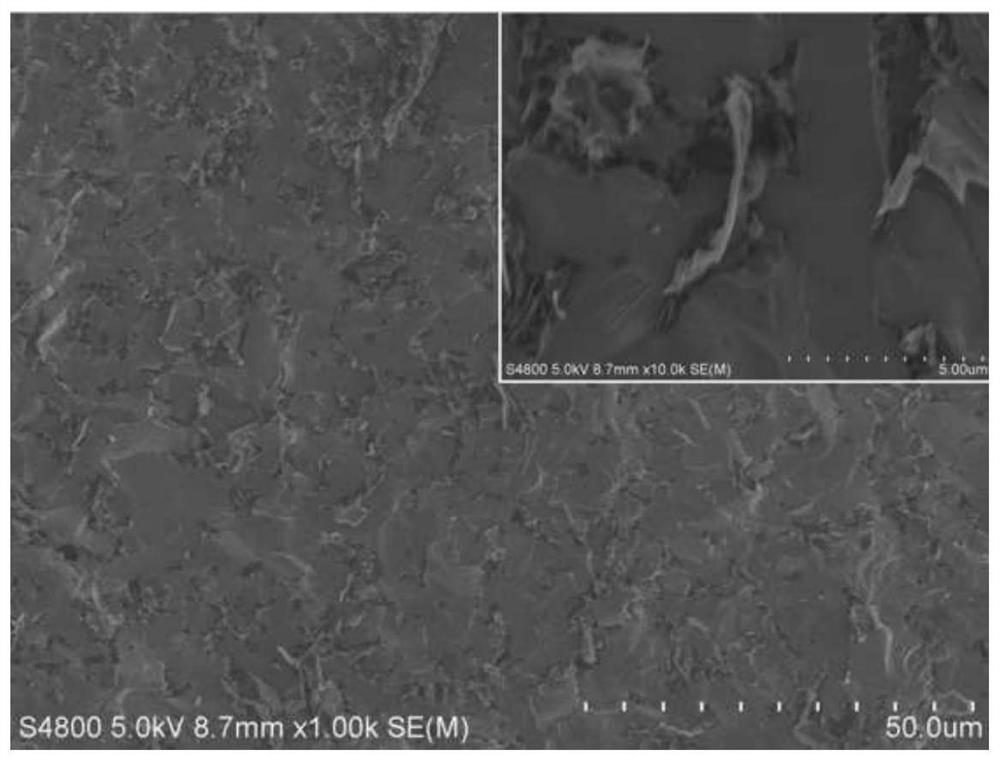

Image

Examples

Embodiment 1

[0036] Embodiment 1. A multi-phase composite reinforced low-friction silicon carbide ceramic sealing material, the raw material is composed of the following components by weight: silicon carbide powder 86%, yttrium aluminum garnet powder 8%, graphene 2.5%, nano-diboron Zirconium 1%, silicon carbide whiskers 2.5%.

[0037] The preparation method is to carry out the following steps in sequence:

[0038] 1), in the raw material of 100 parts by weight, add 110 parts by weight as the deionized water of dispersion medium, 4 parts by weight as the tetramethyl ammonium hydroxide of dispersant, 4 parts by weight as the polyvinyl alcohol of binder, adopt wet The French vertical stirring mill was stirred for 4 hours, then 3 parts by weight of n-octanol as a defoaming agent was added, and the mixture was stirred for 30 minutes to prepare a water-based composite slurry;

[0039] 2), the prepared water-based composite slurry is spray-dried with a high-speed centrifugal spray dryer, the inl...

Embodiment 2

[0043] Example 2. A multi-phase composite reinforced low-friction silicon carbide ceramic sealing material. The weight percentage of the composite ceramic is: 88% silicon carbide powder, 6% yttrium aluminum garnet powder, 1.5% graphene, nanodiboride Zirconium 2.5%, Silicon Carbide Whisker 2%.

[0044] The preparation method is equivalent to Example 1.

[0045] The prepared multiphase composite reinforced low-friction silicon carbide ceramic sealing material has a density of 2.98-3.05g / cm 3 , flexural strength 400 ~ 420MPa, Vickers hardness 22GPa, dry friction coefficient 0.23.

Embodiment 3

[0046] Embodiment 3. A multi-phase composite reinforced low-friction silicon carbide ceramic sealing material. The weight percentage of the composite ceramic is: 87% of silicon carbide powder, 7% of yttrium aluminum garnet powder, 2.5% of graphene, nanodiboride Zirconium 2.5%, silicon carbide whiskers 1.0%.

[0047] The preparation method is equivalent to Example 1.

[0048] The prepared multi-phase composite reinforced low-friction silicon carbide ceramic sealing material has a density of 2.95-3.0 g / cm 3 , flexural strength 380 ~ 390MPa, Vickers hardness 21GPa, dry friction coefficient 0.22.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com