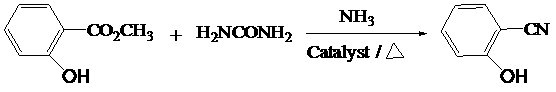

Method for preparing o-hydroxybenzonitrile from methyl salicylate and urea

A technology for o-hydroxybenzonitrile and methyl salicylate, which is applied in the field of preparing o-hydroxybenzonitrile, can solve the problems of high cost of raw materials, short service life of catalysts, heavy environmental pollution, etc., and achieves low cost of raw materials and avoidance of oxidation. , the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Such as figure 1 Shown, a kind of method utilizing methyl salicylate and urea to prepare o-hydroxybenzonitrile comprises the following steps:

[0031] The first step: artificial zeolite, silica gel, alumina, SiO 2 , ZrO 2 Or molecular sieves are weighed according to the ratio of its mass to phosphoric acid mass of 1.0:0.5~15.0, soaked in phosphoric acid aqueous solution with a mass percentage concentration of 10%~80% for 2.0~48.0 hours, then filtered to remove the liquid phase, and the obtained The solid matter is burned in a muffle furnace at 300°C-800°C for 2.0-24.0 hours, and then the solid material burned at high temperature is crushed to a particle size of 50-300 mesh to obtain the immobilized phosphoric acid catalyst;

[0032] Step 2: Weigh methyl salicylate and urea according to the mass ratio of methyl salicylate and urea as 1.0:1.0~6.0, and add methyl salicylate and urea into the reaction bottle;

[0033] Step 3: Install a stirring device, an ammonia gas int...

Embodiment 2

[0040] A preparation using methyl salicylate and urea figure 1 The method for the o-hydroxybenzonitrile of shown structure, comprises the following steps:

[0041] The first step: artificial zeolite, silica gel, alumina, SiO 2 , ZrO 2 Or molecular sieves are weighed according to the ratio of its mass to phosphoric acid mass of 1.0:0.5~15.0, soaked in phosphoric acid aqueous solution with a mass percentage concentration of 10%~80% for 2.0~48.0 hours, then filtered to remove the liquid phase, and the obtained The solid matter is burned in a muffle furnace at 300°C-800°C for 2.0-24.0 hours, and then the solid material burned at high temperature is crushed to a particle size of 50-300 mesh to obtain the immobilized phosphoric acid catalyst;

[0042] Step 2: Weigh methyl salicylate and urea according to the mass ratio of methyl salicylate and urea as 1.0:1.0~6.0, and add methyl salicylate and urea into the reaction bottle;

[0043] Step 3: Install a stirring device, an ammonia g...

Embodiment 3

[0049] A preparation using methyl salicylate and urea figure 1 The method for the o-hydroxybenzonitrile of shown structure, comprises the following steps:

[0050] The first step: artificial zeolite, silica gel, alumina, SiO 2 , ZrO 2 Or molecular sieves are weighed according to the ratio of its mass to phosphoric acid mass of 1.0:0.5~15.0, soaked in phosphoric acid aqueous solution with a mass percentage concentration of 10%~80% for 2.0~48.0 hours, then filtered to remove the liquid phase, and the obtained The solid matter is burned in a muffle furnace at 300°C-800°C for 2.0-24.0 hours, and then the solid material burned at high temperature is crushed to a particle size of 50-300 mesh to obtain the immobilized phosphoric acid catalyst;

[0051] Step 2: Weigh methyl salicylate and urea according to the mass ratio of methyl salicylate and urea as 1.0:1.0~6.0, and add methyl salicylate and urea into the reaction bottle;

[0052] Step 3: Install a stirring device, an ammonia g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com