High-molecular-weight high-flexibility bio-based polycarbonate copolymer and preparation method thereof

A polycarbonate, high molecular weight technology, applied in the field of polycarbonate preparation, can solve the problems of unsatisfactory industrial use, poor mechanical properties and processability, and achieve the effects of easy rotation, improved mechanical properties, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At room temperature, 6.43g diphenyl carbonate, 3.07g isosorbide, 1.75g tetraethylene glycol (HO-CH 2 CH 2 -O-CH 2 CH 2 -O-CH 2 CH2 -O-CH 2 CH 2 -OH) into a 250ml three-necked flask, under nitrogen atmosphere protection, after heating up to 130°C, add catalyst 1-butyl-3-methylimidazole lactate, the amount of catalyst is 0.005mol% of the amount of diphenyl carbonate. Stir at 130°C for 3 hours for transesterification reaction, then gradually increase the temperature and gradually lower the pressure to 240°C, 50 Pa, keep for 0.5 hour, the reaction is completed, and the copolymer is obtained with a yield of 98%. The reaction product was characterized, and a polycarbonate copolymer with a number average molecular weight of 121000 g / mol was obtained.

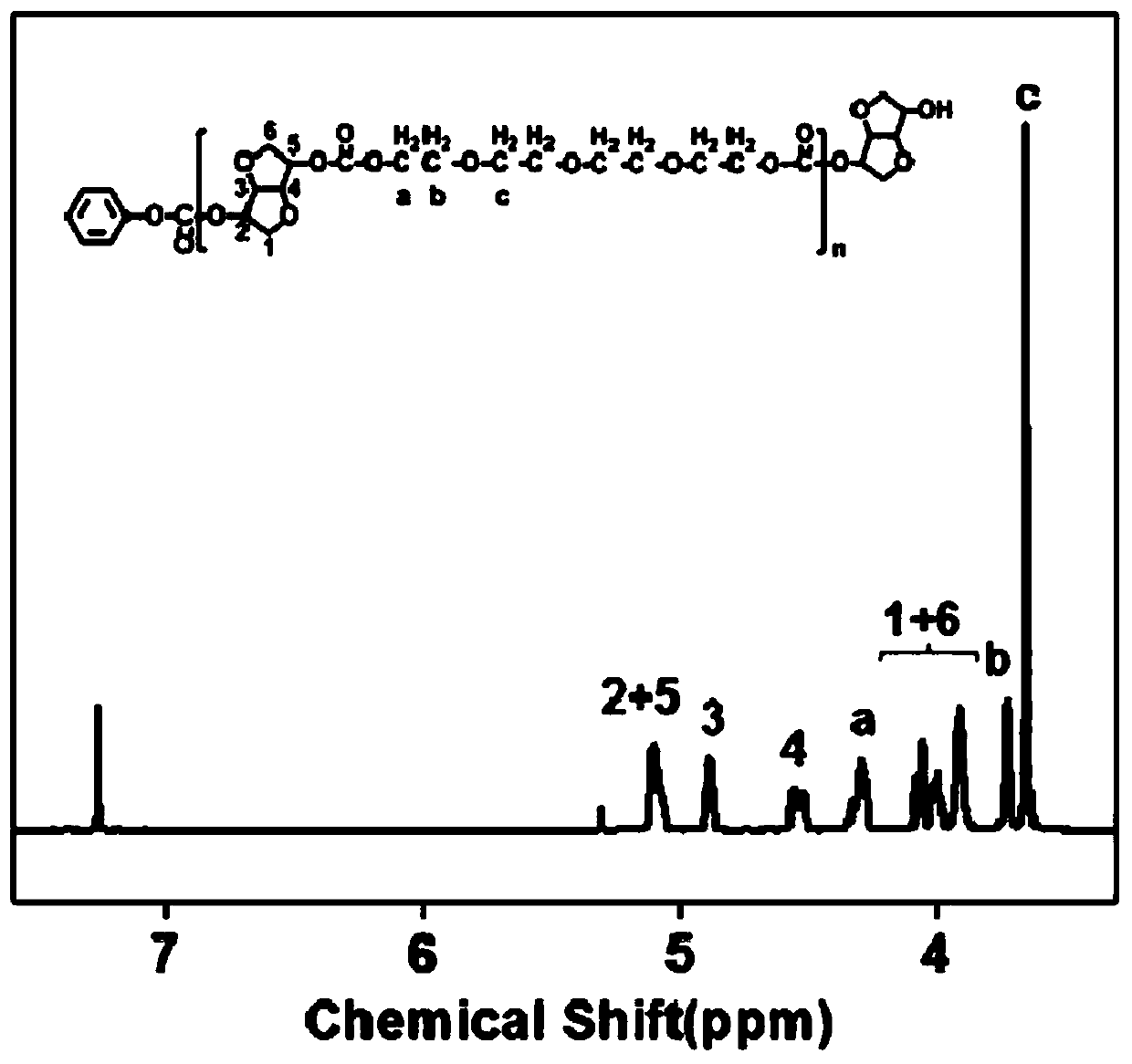

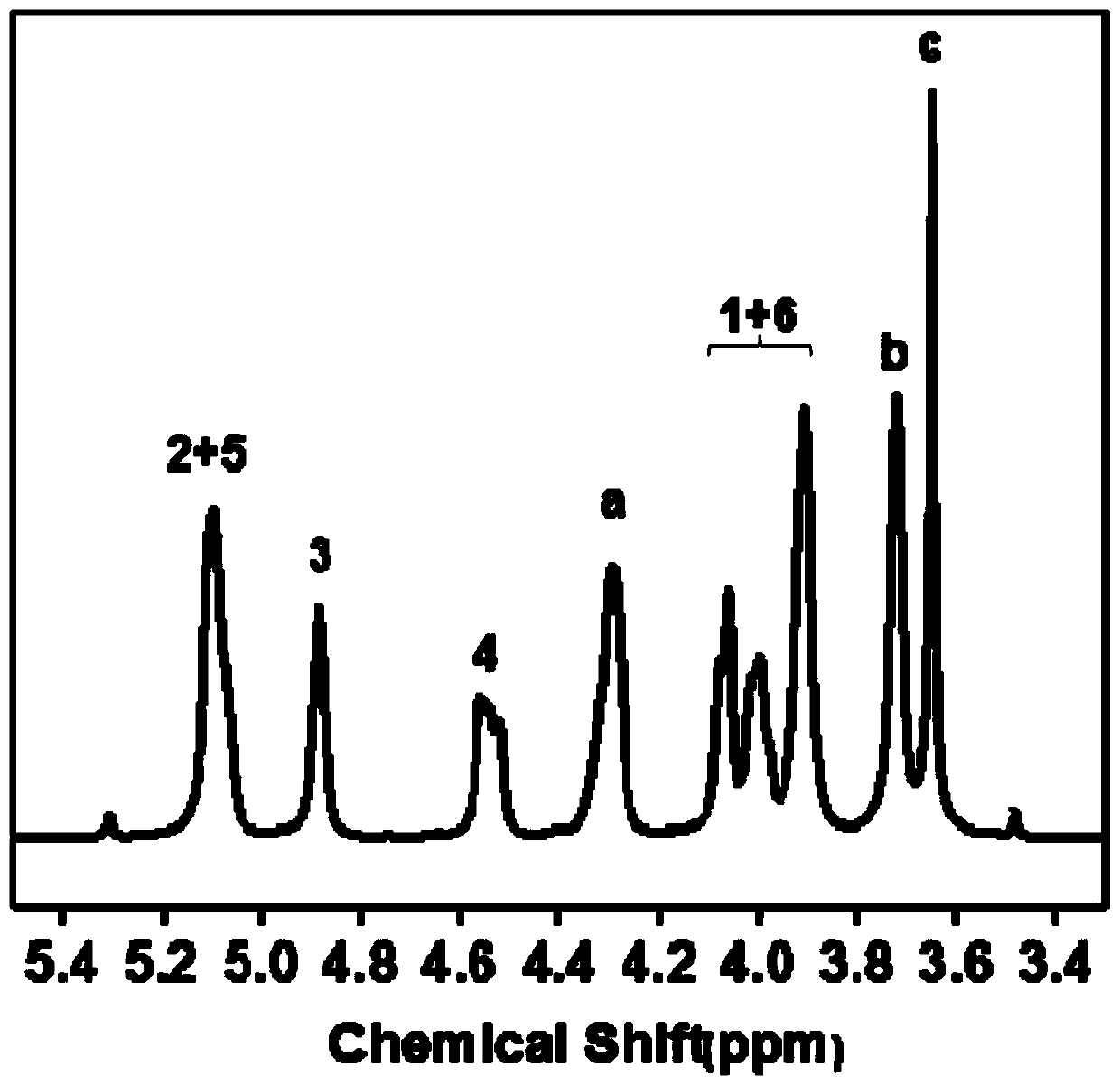

[0032] Copolymer 1 H-NMR spectrum as figure 1 As shown, it shows that the copolymer structure is correct; the glass transition temperature of the copolymer measured by DSC is 72°C, and the 5% thermal weight loss temper...

Embodiment 2

[0034] Same as in Example 1, except that the temperature in the transesterification stage was 110° C., other conditions remained unchanged to obtain a copolymer with a yield of 98%. The reaction product was characterized to obtain a polycarbonate copolymer with a number average molecular weight of 60000 g / mol.

Embodiment 3

[0036] Same as in Example 1, except that the temperature in the transesterification stage was 150° C., other conditions remained unchanged to obtain a copolymer with a yield of 98%. The reaction product was characterized to obtain a polycarbonate copolymer with a number average molecular weight of 65000 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Variable temperature | aaaaa | aaaaa |

| Thermogravity temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com