Efficient antibacterial environment-friendly coating and preparation method thereof

A technology of antibacterial coatings and environmentally friendly coatings, applied in the field of high-efficiency and environmentally friendly antibacterial coatings and their preparation, can solve the problems of untargeted application of cinnamic acid and kaempferol, etc., and achieve the effects of prolonging service life, lasting antibacterial ability, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of preparation method of high-efficiency antibacterial environmental protection paint, specifically comprises the following steps:

[0033] Add 5-10 parts of pH adjuster to 20-30 parts of deionized water, stir for 5-10 minutes at a stirring rate of 300-500r / min; increase the stirring rate to 800-1000r / min, and add 20-30 parts of cinnamic acid in turn Kaempferol ester, 1-5 parts of wetting agent, 5-10 parts of titanium dioxide and 20-30 parts of calcium carbonate; again increase the stirring speed to 1800-2000r / min, stir for 15-20min; reduce the stirring speed to 1000-1200r / min min, add 80-100 parts of water-based acrylic emulsion and 2-6 parts of film-forming aid in sequence, and stir for 10-15 minutes to obtain an environmentally friendly antibacterial coating.

[0034] The above-mentioned stirring rate has been changed many times. The inventor found in the experiment that the multiple changes of the stirring rate can make the different components mix more fully...

Embodiment 1

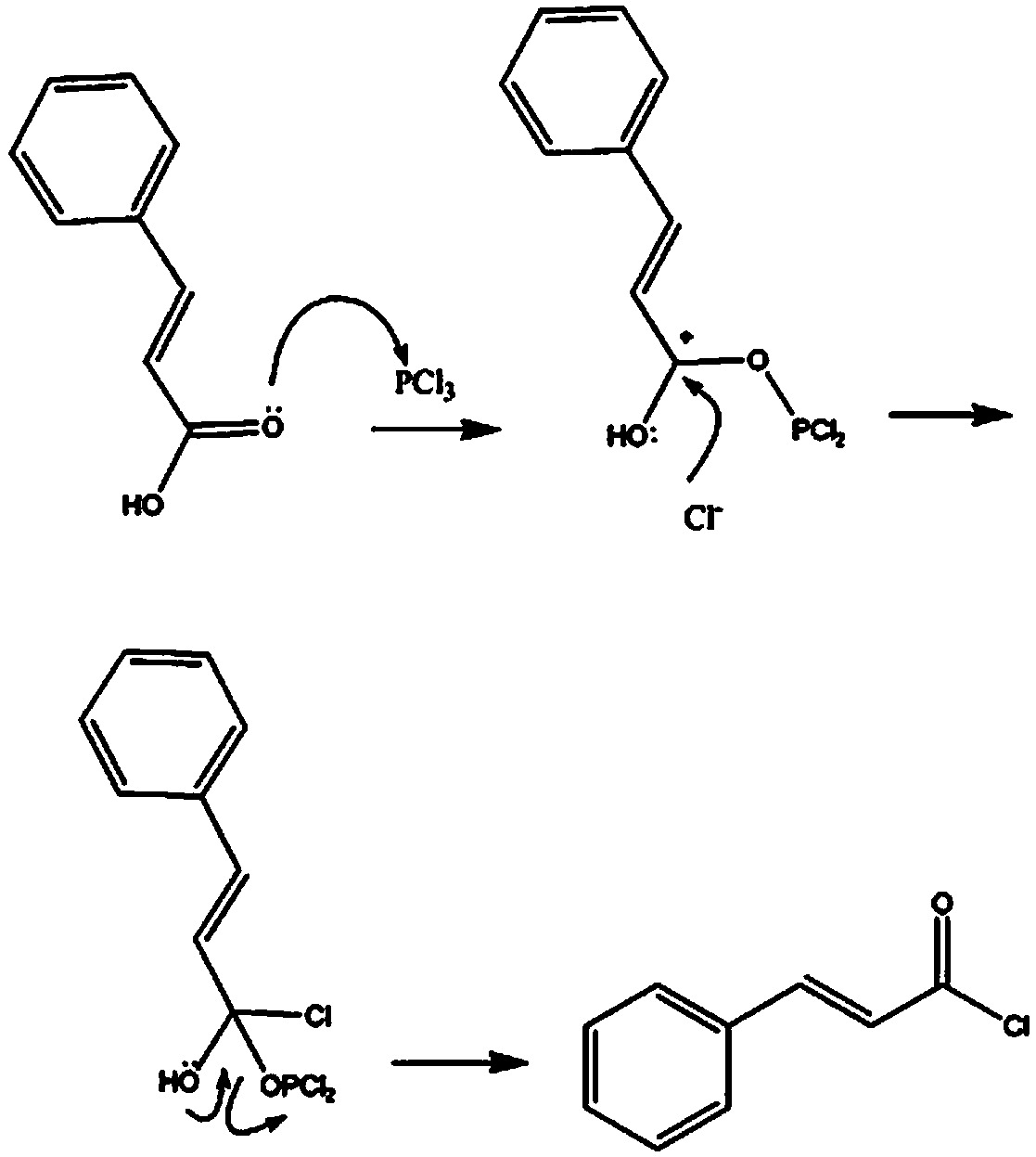

[0044]Step 1: Preparation of Cinnamoyl Chloride

[0045] (1) Put 10 parts of cinnamic acid into an anhydrous and dry 25ml round bottom flask, add 10 parts of anhydrous and dry DCM, and add dry and anhydrous magnetons;

[0046] (2) Sonicate in an ultrasonic cleaner until there is no solid on the surface, place it on a magnetic stirrer, and add 4ml of PCl under stirring in a ventilated place 3 ;

[0047] (3) React under stirring at room temperature until it becomes a yellow, clear and transparent liquid. 2 ) in a rotary evaporator at 30°C to dryness under reduced pressure to obtain cinnamoyl chloride.

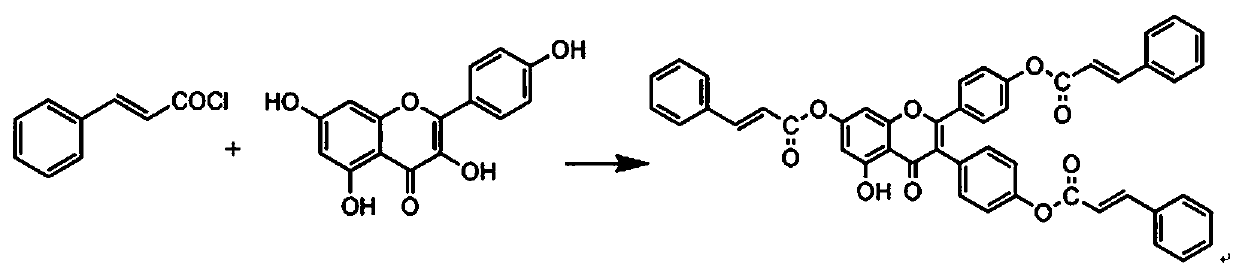

[0048] Step 2: Preparation of environment-friendly antibacterial agent

[0049] (1) In a 10ml round bottom flask, add 10 parts of kaempferol and dissolve with 2 parts of anhydrous tetrahydrofuran;

[0050] (2) Add 10 parts of cinnamoyl chloride and 2 parts of triethylamine under ice bath conditions;

[0051] (3) After adding, stir and react at room temperature for 2 h, and d...

Embodiment 2

[0058] Step 1: Preparation of Cinnamoyl Chloride

[0059] Same as Example 1

[0060] Step 2: the preparation of kaempferol cinnamate:

[0061] (1) In a 10ml round bottom flask, add 10 parts of kaempferol and dissolve with 2 parts of anhydrous tetrahydrofuran;

[0062] (2) Add 20 parts of cinnamoyl chloride and 4 parts of triethylamine under ice bath conditions;

[0063] (3) After adding, stir and react at room temperature for 2 h, and distill THF under reduced pressure after the reaction finishes;

[0064] (4) Add 3 parts of water, extract three times with 2 parts of dichloromethane, anhydrous NaSO 4 Dry and concentrate to obtain kaempferol cinnamate.

[0065] Step three:

[0066] (1) Control the stirring rate to 300-500rmp, add 25 parts of deionized water and 8 parts of AMP-95PH regulator in turn to the stirrer, and stir for 5-10min;

[0067] (2) Then increase the speed to 800-1000r / min, add 25 parts of kaempferol cinnamate environmental protection antibacterial agents,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com