Elastic polyurethane fiber with excellent antibacterial property and preparation method thereof

A technology of polyurethane elasticity and polyurethane elastomer, which is applied in the preparation and application of branched quaternary ammonium salts and their antibacterial composite materials, can solve the problems that have not been seen, the poor compatibility of matrix materials, and the influence of spandex spinnability, etc., to achieve Increased versatility, long-lasting antimicrobial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of preparation method of the polyurethane elastic fiber with excellent antibacterial performance of the present invention comprises the following steps:

[0035] (1) Prepolymerization reaction is carried out by polytetramethylene ether glycol and 4,4-diphenylmethane diisocyanate in N,N-dimethylacetamide solution, and then ethylenediamine, 1,2- A mixture of propylenediamine and diethylamine undergoes a chain extension reaction to obtain a polyurethane stock solution;

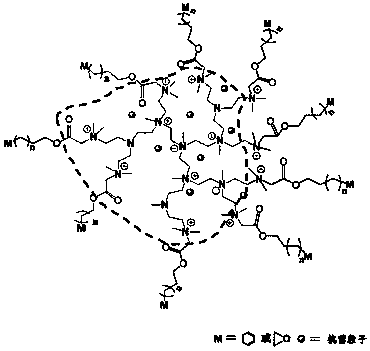

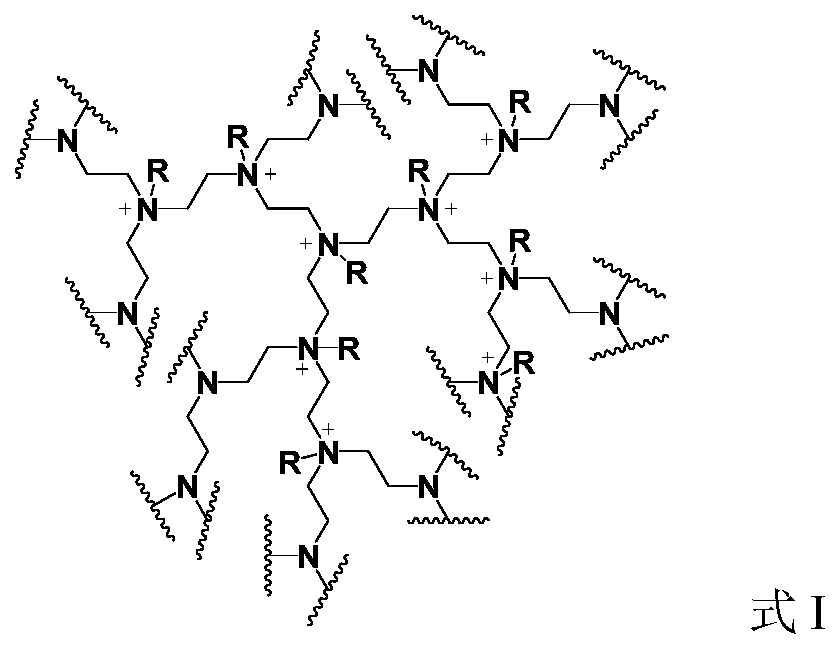

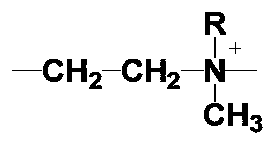

[0036] (2) Synthesize branched quaternary ammonium salts and prepare composite materials containing coated antibacterial particles;

[0037] (3) Combine branched quaternary ammonium salt antibacterial composite material, N,N-dimethylacetamide, anti-ultraviolet additive UV-320, dyeing auxiliary agent SAS, matting agent titanium dioxide and lubricant magnesium stearate with a part of the above-mentioned polyurethane The stock solution is fully mixed in the grinder to form a low-viscosity additive slu...

Embodiment 1

[0052] Step 1. (1) Dissolve 1 kg of branched polyethyleneimine in water, add 0.046 kg of formic acid and 0.015 kg of formaldehyde, and carry out amine methylation reaction at 70 ° C for 1 day to obtain methylated branched polyethylene Imine; (2) Dissolve the methylated branched polyethylene obtained in (1) in DMAC solution, add 0.0293kg glycidyl bromoacetate, and react at 50°C for 1 day to obtain branched polyquaternium Salt solution: adding 10 g of nanometer silver into the prepared branched quaternary ammonium salt solution, fully stirring and mixing to obtain a branched quaternary ammonium salt composite material containing inorganic antibacterial particles.

[0053] Step 2. Add 10.8kg polytetramethylene ether glycol (molecular weight 1810) and 2.535kg 4,4-diphenylmethane diisocyanate into the RA1 reactor at the same time, the reaction temperature is 65°C, and the reaction time is 2 hours to obtain a certain mass Fractional -NCO-terminated prepolymer PP; add 20.1kg of DMAC,...

Embodiment 2

[0056] Step 1. (1) Dissolve 1 kg of branched polyethyleneimine in water, add 0.046 kg of formic acid and 0.015 kg of formaldehyde, and carry out amine methylation reaction at 70 ° C for 1 day to obtain methylated branched polyethylene Imine; (2) Dissolve the methylated branched polyethylene obtained in (1) in DMAC solution, add 0.0293kg glycidyl bromoacetate, and react at 50°C for 1 day to obtain branched polyquaternium Salt solution: adding 10 g of nanometer silver into the prepared branched quaternary ammonium salt solution, fully stirring and mixing to obtain a branched quaternary ammonium salt composite material containing inorganic antibacterial particles.

[0057] Step 2. Add 10.8kg polytetramethylene ether glycol (molecular weight 1810) and 2.535kg 4,4-diphenylmethane diisocyanate into the RA1 reactor at the same time, the reaction temperature is 65°C, and the reaction time is 2 hours to obtain a certain mass Fractional -NCO-terminated prepolymer PP; add 20.1kg of DMAC,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com