Aldehyde nucleophilic addition complexing antibacterial fibers as well as preparation method and application thereof

An antibacterial fiber, aldehyde nucleophilic technology, applied in the field of textiles, can solve the problems of insufficient binding force of textiles, short duration of antibacterial properties, low grafting rate, etc., achieving good technical feasibility and economic value, and industrial large-scale production. Easy, simple and simple processing techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] In this specification, all parts are by weight unless otherwise stated.

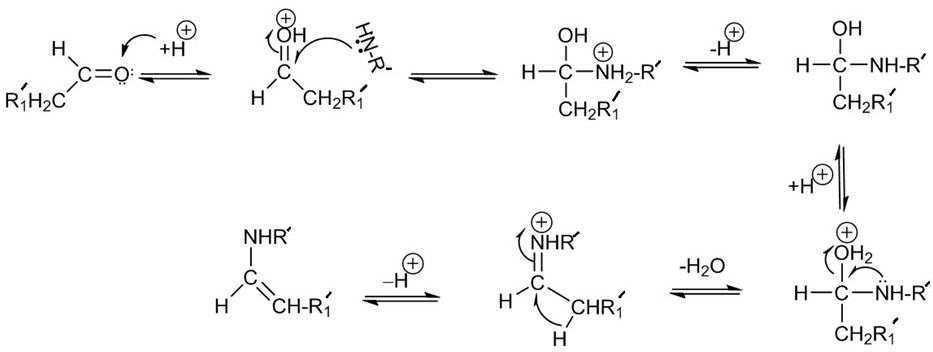

[0048] A preparation method of aldehyde nucleophilic addition complexation antibacterial fiber, the fiber to be modified is selected as a raw material, and the sugar unit of the cellulose to be modified contains at least one aldehyde active group;

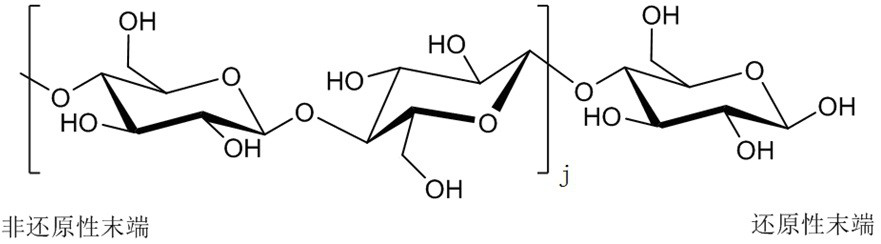

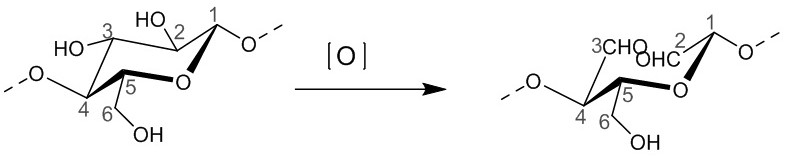

[0049] like figure 1 As shown, in the present invention, cellulose fibers can be divided into natural cellulose fibers such as cotton, hemp and regenerated cellulose fibers such as Lyocell, Modal fibers, bamboo fibers, cupro fibers and the like. This type of fiber is composed of cellulose, which is a macromolecular polysaccharide composed of glucose, which is insoluble in water and general organic solvents. Its reducing end is easily isomerized to aldehyde (-CHO), which has good reactivity. Additionally, if figure 2 As shown, the secondary hydroxyl groups at the 2 and 3 positions also have strong activity and can be oxidized to aldehyde groups unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com