Co3O4-based heat storage type catalyst, and preparation method and application thereof in catalyzing methane combustion

A catalyst and heat storage technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of flying temperature and hot spots, and reduce energy utilization efficiency. , affecting the system economy and other issues, to achieve the effect of improving the thermal environment of the bed, improving the combustion and heating efficiency, and excellent catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

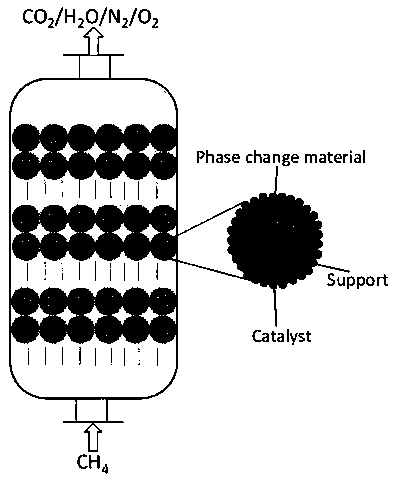

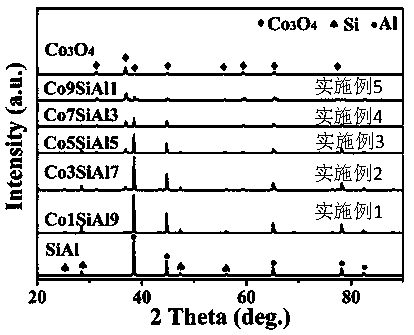

[0044] Example 1: Co 3 o 4 based regenerative catalysts (see figure 1 ), the active component is Co 3 o 4 , the carrier is a core-shell structure SiAl@Al 2 o 3 Phase change heat storage material, based on the mass percentage of the catalyst, the active component accounts for 10%, and the core-shell structure carrier SiAl@Al 2 o 3 90%;

[0045] co 3 o 4 The preparation method of base regenerative catalyst, concrete steps are as follows:

[0046] (1) SiAl@Al 2 o 3 The composite heat storage material is ultrasonically dispersed into the cobalt nitrate solution to obtain a mixed solution A; the concentration of the cobalt nitrate solution is 0.05mol / L, the ultrasonic power is 100W, and the ultrasonic treatment time is 120min;

[0047] (2) Under the condition of a stirring rate of 200 r / min, add the sodium carbonate solution dropwise to the mixed solution A in step (1) to react until the pH value of the system is 9.0, and continue stirring for 120 minutes to obtain the ...

Embodiment 2

[0049] Example 2: Co 3 o 4 based regenerative catalysts (see figure 1 ), the active component is Co 3 o 4 , the carrier is a core-shell structure SiAl@Al 2 o 3 Phase change heat storage material, based on the mass percentage of the catalyst, the active component accounts for 30%, and the core-shell structure carrier SiAl@Al 2 o 3 70%;

[0050] co 3 o 4 The preparation method of base regenerative catalyst, concrete steps are as follows:

[0051] (1) SiAl@Al 2 o 3 The composite heat storage material was ultrasonically dispersed into the cobalt nitrate solution to obtain a mixed solution A; the concentration of the cobalt nitrate solution was 0.1 mol / L, the ultrasonic power was 100W, and the ultrasonic treatment time was 120min;

[0052] (2) At a stirring rate of 300 r / min, add the sodium carbonate solution dropwise to the mixed solution A in step (1) to react until the pH value of the system is 10.5, and continue stirring for 130 min to obtain the mixed solution B; ...

Embodiment 3

[0054] Example 3: Co 3 o 4 based regenerative catalysts (see figure 1 ), the active component is Co 3 o 4 , the carrier is a core-shell structure SiAl@Al 2 o 3 Phase change heat storage material, based on the mass percentage of the catalyst, the active component accounts for 50%, and the core-shell structure carrier SiAl@Al 2 o 3 50%;

[0055] co 3 o 4 The preparation method of base regenerative catalyst, concrete steps are as follows:

[0056] (1) SiAl@Al 2 o 3 The composite heat storage material is ultrasonically dispersed into the cobalt nitrate solution to obtain a mixed solution A; the concentration of the cobalt nitrate solution is 0.2mol / L, the ultrasonic power is 100W, and the ultrasonic treatment time is 120min;

[0057] (2) Under the condition of stirring rate of 400r / min, add the sodium carbonate solution dropwise to the mixed solution A in step (1) to react until the pH value of the system is 10.0, and continue stirring for 150 minutes to obtain the mix...

PUM

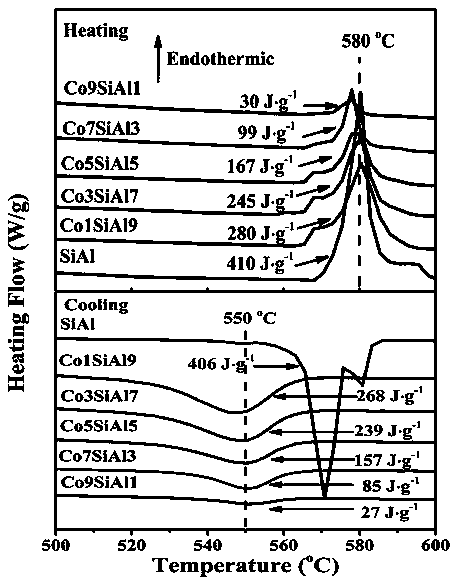

| Property | Measurement | Unit |

|---|---|---|

| enthalpy of fusion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com