Blue niobium pentoxide, and preparation method and application thereof

A niobium pentoxide and blue technology, applied in the field of niobium pentoxide, can solve problems such as the inability to use visible light and near-infrared light energy, medical application limitations, etc., and achieve mass production, low price, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of blue niobium pentoxide, comprises the steps: with 0.3g NbCl 5 Dissolve in 50mL of absolute ethanol, put it in an oven at 60°C for 6 hours to completely evaporate the absolute ethanol, and obtain the amorphous niobium oxide precursor; wash the amorphous niobium oxide precursor, dry it, and then put it into a corundum crucible Inside, put it in a high-temperature muffle furnace, raise the temperature to 500°C at a rate of 5°C / min, heat-preserve and calcinate for 3 hours, and cool down to room temperature to obtain white niobium pentoxide; add 0.1g of white niobium pentoxide to a concentration of 4M hydrochloric acid Ultrasonic disperse in the aqueous solution, then add 0.2g of zinc powder, stir for 10 minutes, centrifuge, take the precipitate, wash, and dry to obtain blue niobium pentoxide.

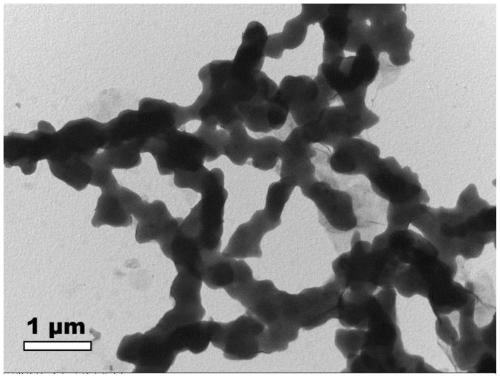

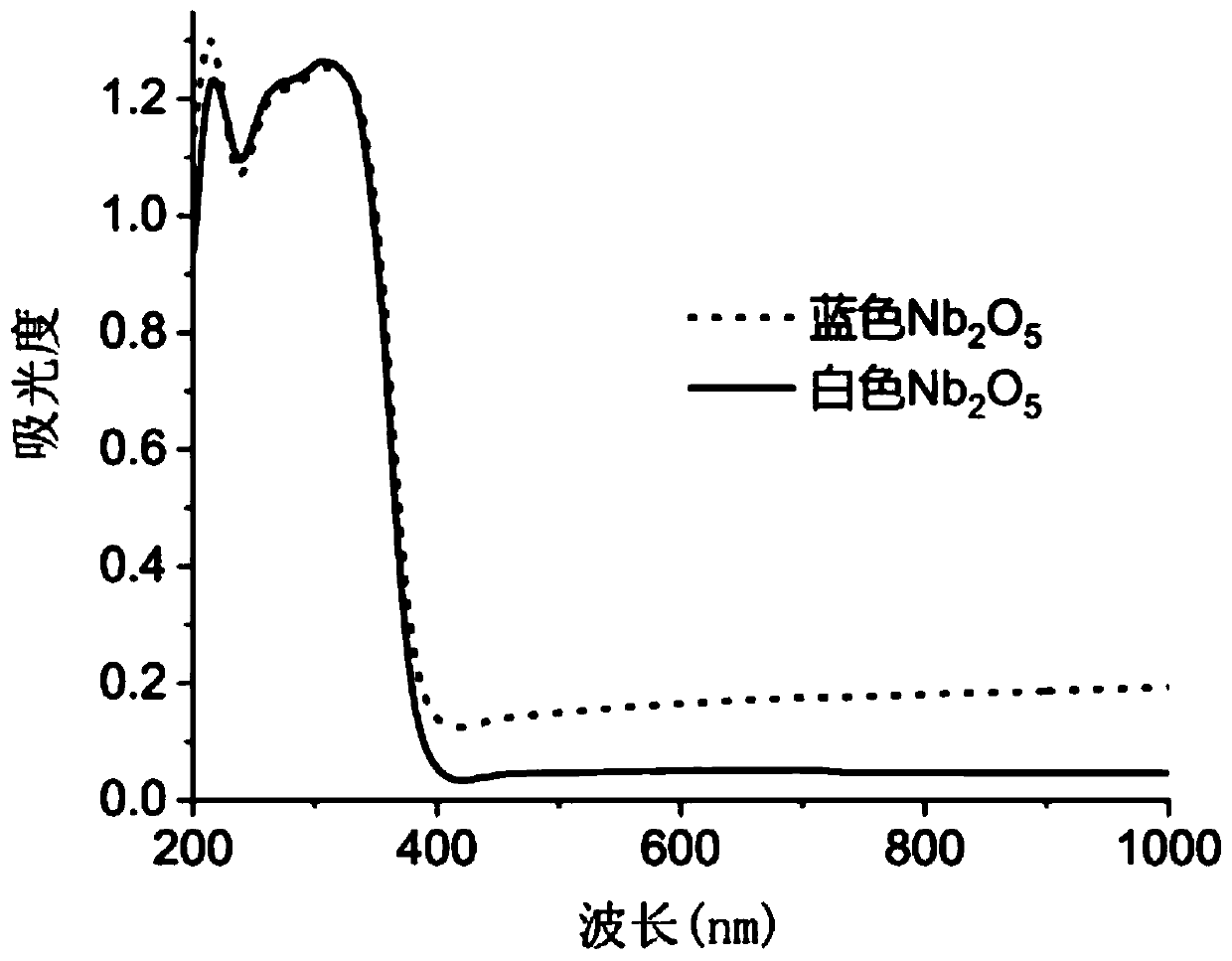

[0030] Take the above-mentioned blue niobium pentoxide and white niobium pentoxide for detection, the results can be found in Figure 1-2 , figure 1...

Embodiment 2

[0035] A kind of preparation method of blue niobium pentoxide, comprises the steps: with 0.5g NbCl 5 Dissolve in 50mL of absolute ethanol, put it in an oven at 60°C for 12 hours to completely evaporate the absolute ethanol, and obtain the amorphous niobium oxide precursor; wash the amorphous niobium oxide precursor, dry it, and then put it into a corundum crucible Inside, put it in a high-temperature muffle furnace, raise the temperature to 600°C at a rate of 5°C / min, keep the heat for calcination for 4 hours, and cool down to room temperature to obtain white niobium pentoxide; add 0.2g of white niobium pentoxide to a concentration of 4M hydrochloric acid Ultrasonic disperse in the aqueous solution, then add 0.3g of zinc powder, stir for 15 minutes, centrifuge, take the precipitate, wash it, and dry it to obtain blue niobium pentoxide.

Embodiment 3

[0037] A kind of preparation method of blue niobium pentoxide, comprises the steps: with 0.1g NbCl 5 Dissolve in 50mL of methanol, put it in an oven at 60°C for 5h to completely evaporate the methanol, and obtain the amorphous niobium oxide precursor; wash the amorphous niobium oxide precursor, dry it, put it into a corundum crucible, and place In a high-temperature muffle furnace, heat up to 580°C at a rate of 10°C / min, heat-preserve and calcine for 2 hours, and cool down to room temperature to obtain white niobium pentoxide; add 0.3g of white niobium pentoxide to 6M hydrochloric acid aqueous solution for ultrasonic dispersion , then add 0.1g magnesium powder, stir for 20min, centrifuge, take the precipitate, wash, dry to obtain blue niobium pentoxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com