High-temperature-resistant acetenyl-terminated polyimide material and preparation method thereof

A technology of polyimide and end-imide acid, applied in the direction of adhesives, etc., can solve the problems of brittle material and narrow processing window, and achieve the effect of weakening interaction force, high temperature resistance and lowering softening point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

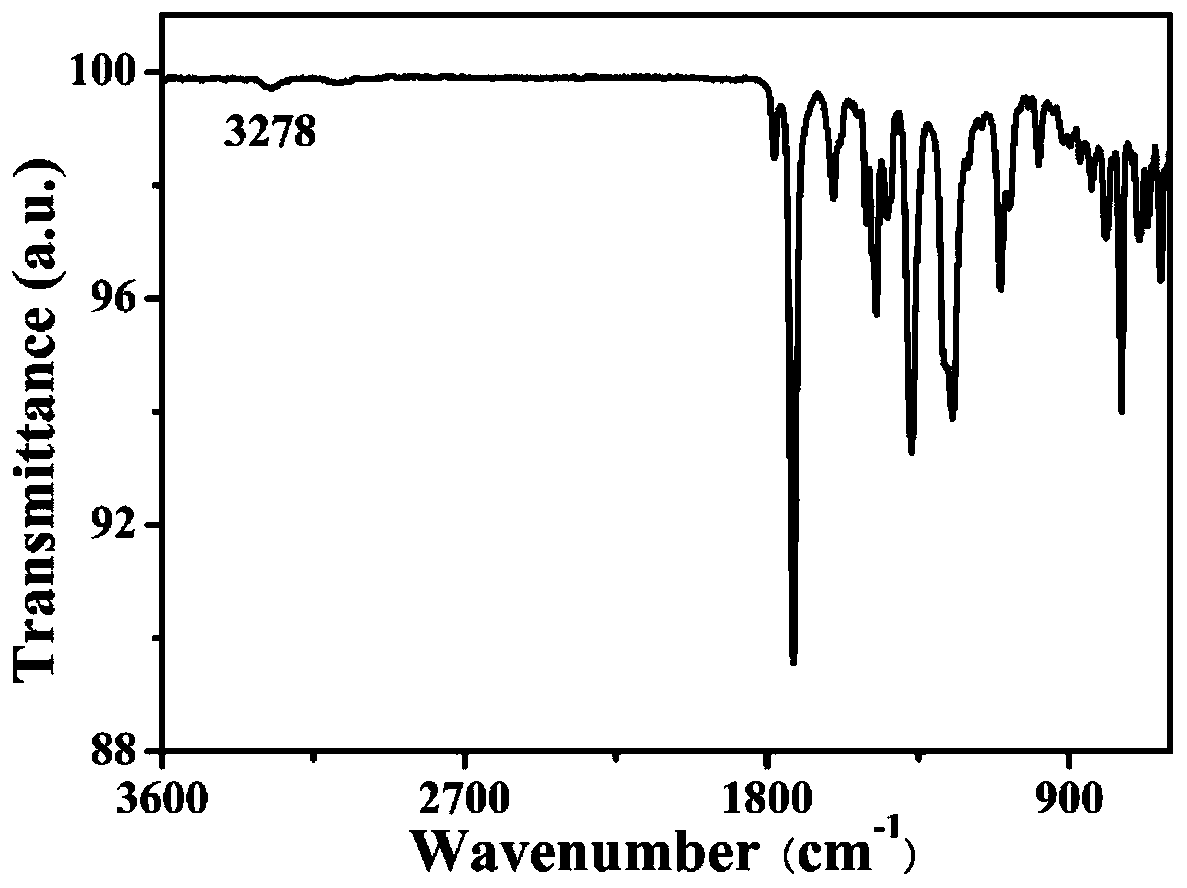

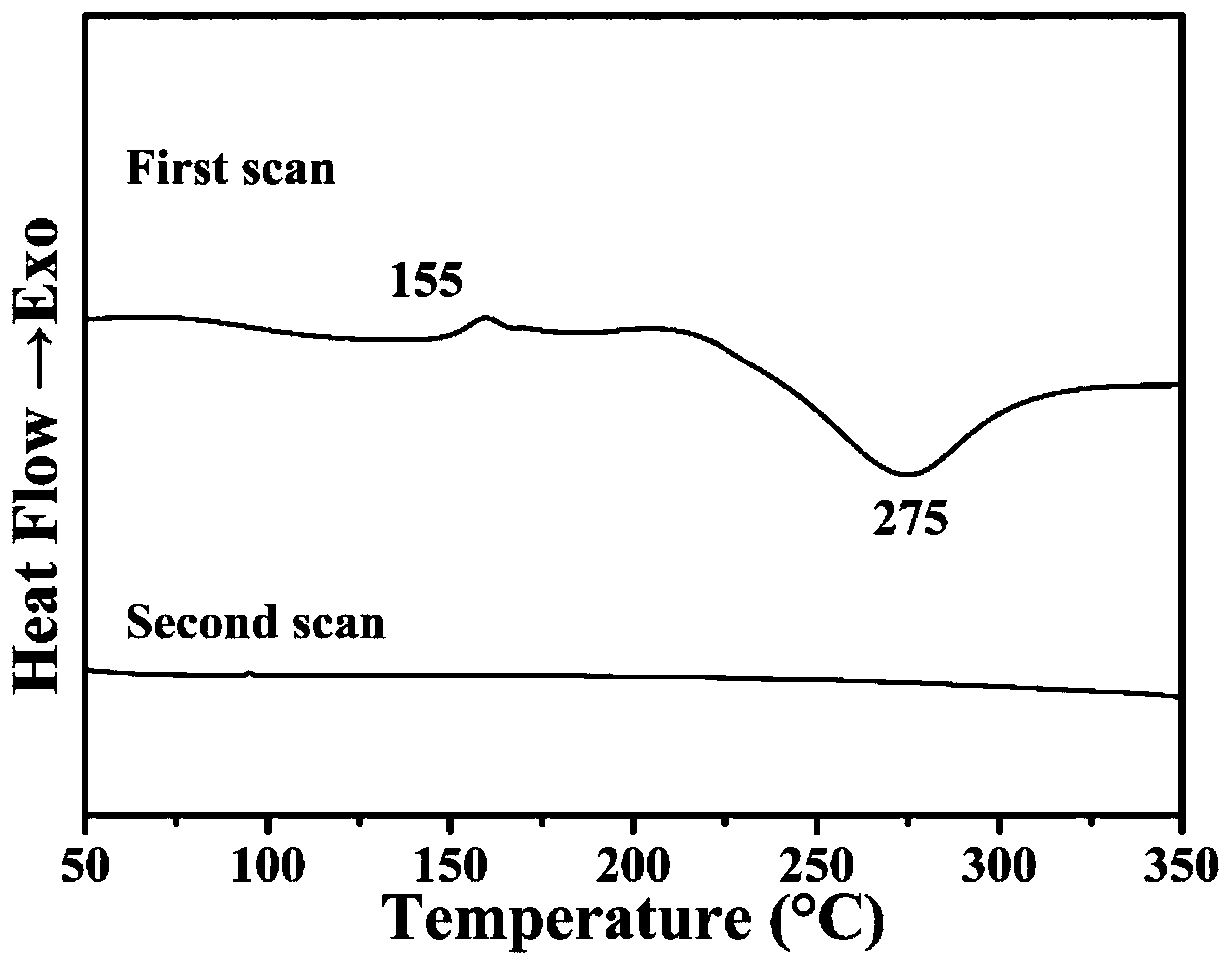

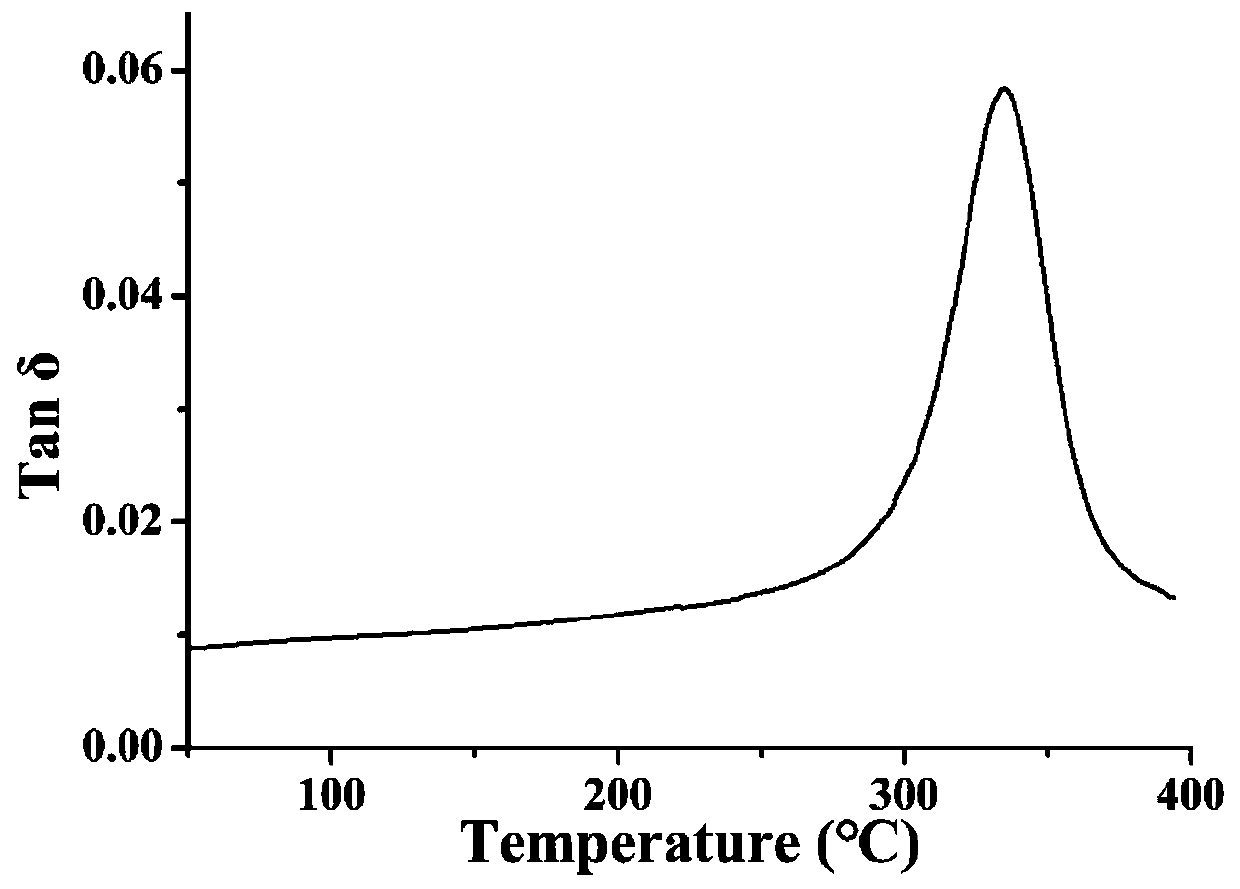

Image

Examples

Embodiment 1

[0047] The preparation method of the high temperature resistant acetylene group-terminated polyimide material of the present invention, the detailed steps of this preparation method are as follows:

[0048] a. First, under the protection of nitrogen, 50g of N,N-dimethylacetamide was added to a three-necked round-bottomed flask with mechanical stirring, and then 8g of 4-phenoxy m-phenylenediamine was added to fully dissolve;

[0049] b. When 4-phenoxym-phenylenediamine is completely dissolved in step a, add 24.8g of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and 50g of N,N-dimethylacetamide , and then stirred and reacted at 30°C for 6h;

[0050] c. After the reaction in step b, add 9.36 g of end-capping agent 3-ethynylaniline and N,N-dimethylacetamide, control the solid content of the solution to 20%, and continue the reaction at 30°C for 24 hours to obtain ethynyl-capped Terminal imidic acid solution;

[0051] d. Add 48.48 g of triethylamine and 48.96 g of acetic a...

Embodiment 2

[0055] The preparation method of the high temperature resistant acetylene group-terminated polyimide material of the present invention, the detailed steps of this preparation method are as follows:

[0056] a. First, under the protection of nitrogen, 50g of N-methylpyrrolidone NMP is added to a three-necked round-bottomed flask with mechanical stirring, and then 11.04g of 4-(4'-biphenyloxy) m-phenylenediamine is added, fully dissolved;

[0057] b. When 4-(4'-biphenoxy) m-phenylenediamine is completely dissolved in step a, add 24.8g of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and 50g of N-methyl Basepyrrolidone NMP, then stirred and reacted at 60°C for 9h;

[0058] c. After the reaction in step b, add 9.36 g of end-capping agent 3-ethynyl aniline and N-methylpyrrolidone NMP, control the solid content of the solution to 20%, and continue the reaction at 60°C for 24 hours to obtain ethynyl-terminated acylidene Amino acid solution;

[0059] d. Add 32.32 g of triethy...

Embodiment 3

[0062] The preparation method of the high temperature resistant acetylene group-terminated polyimide material of the present invention, the detailed steps of this preparation method are as follows:

[0063] a. First, under the protection of nitrogen, 60g of 1,4-dioxane was added to a three-necked round-bottomed flask with mechanical stirring, and then 8g of 4-phenoxy m-phenylenediamine was added to fully dissolve;

[0064] b. When 4-phenoxym-phenylenediamine is completely dissolved in step a, add 24.8g of 2,3,3',4'-diphenyl ether tetracarboxylic dianhydride and 60g of 1,4-dioxane, Then the reaction was stirred and reacted at 40°C for 8h;

[0065] c. After the reaction in step b, add 9.36 g of end-capping agents 3-ethynylaniline and 1,4-dioxane, control the solid content of the solution to 15%, and continue the reaction at 40°C for 12 hours to obtain ethynyl end-capping imidic acid solution;

[0066] d. Add 48.48 g of triethylamine and 100.08 g of trifluoroacetic anhydride dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com