Inorganic composite phase-change energy storage material and preparation method thereof

A phase-change energy storage material and inorganic composite technology, applied in the field of inorganic composite phase-change energy storage materials and their preparation, can solve the problems of large supercooling, achieve high energy utilization, shorten phase change time, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

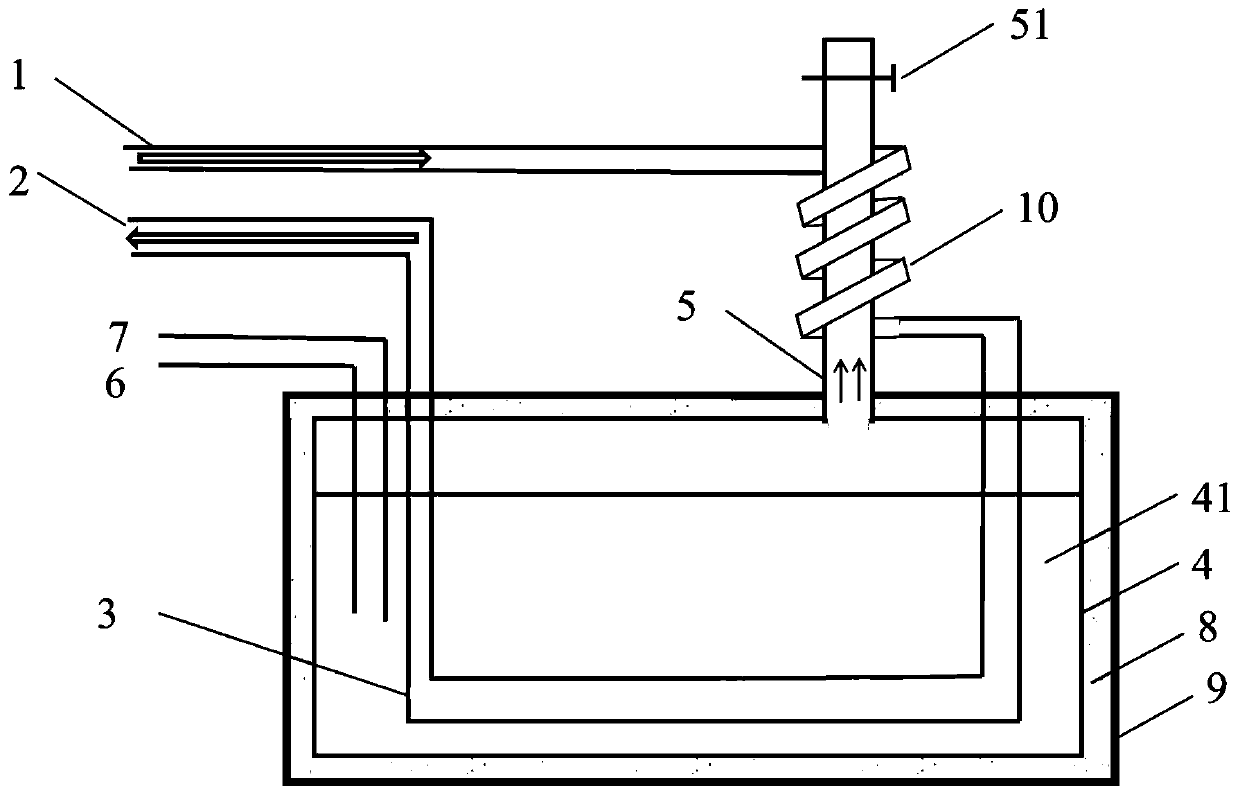

preparation example Construction

[0070] The second aspect of the present invention provides a method for preparing an inorganic composite phase-change energy storage material, preferably a method for preparing the phase-change energy storage material described in the first aspect of the present invention, the method comprising the following steps:

[0071] Step 1. Weighing energy storage main material, nucleating agent and buffering agent;

[0072] Step 2, mixing the energy storage main material, nucleating agent and buffering agent in step 1 in a container to obtain a mixture;

[0073] Step 3, heating the mixture obtained in step 2;

[0074] Step 4, cooling and molding to obtain an inorganic composite phase change energy storage material.

[0075] According to the present invention, in step 1, the energy storage main material, nucleating agent and buffering agent are weighed according to the following weight proportions: 50-99 parts by weight of the main energy storage material; 0.1-20 parts by weight of th...

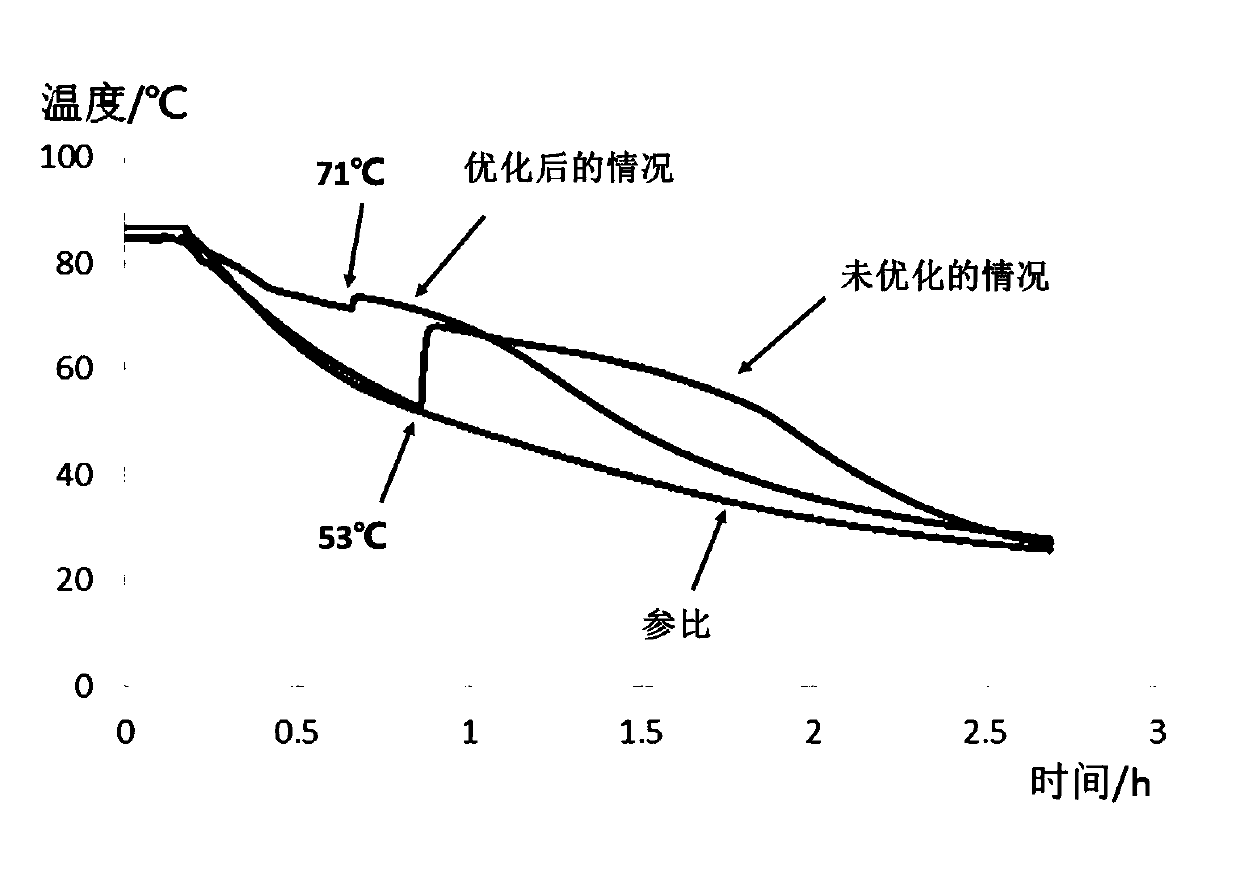

Embodiment 1

[0130] Weigh 100 g of barium hydroxide octahydrate, 5 g of polypropylene fiber, and 40 g of a saturated solution of barium hydroxide octahydrate;

[0131] Weaving the polypropylene fiber into a net shape on the anti-corrosion support, placing it in a container, then adding barium hydroxide octahydrate and a saturated solution of barium hydroxide octahydrate to the container, and mixing evenly to obtain a mixture;

[0132] Then the mixture was heated in an oil bath at 85°C until the octahydrate barium hydroxide was completely melted;

[0133] The melted mixture is naturally cooled and molded to obtain an inorganic composite phase change energy storage material.

Embodiment 2

[0135] Repeat the preparation process of Example 1, the only difference is that 5g of aramid fiber is weighed, and other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com