Non-contact Bridge Displacement Sensing Method Based on Flexible Photoelectric Sensing Array

A photoelectric sensing and non-contact technology, applied in the direction of optical devices, instruments, measuring devices, etc., can solve the problems of centimeter level, unusable, low measurement accuracy, etc., and achieve good ductility and denaturation ability, Increased measurement stability and reduced data loss effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

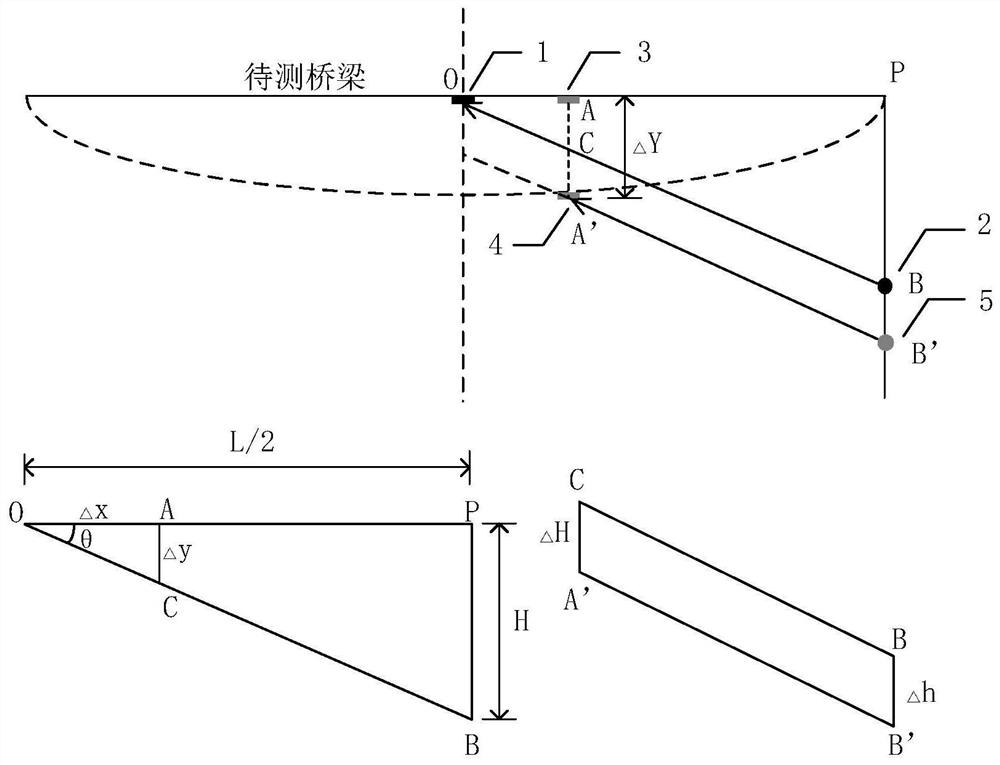

[0021] The purpose and effects of the present invention will become clearer by describing the present invention in detail according to the accompanying drawings and preferred embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

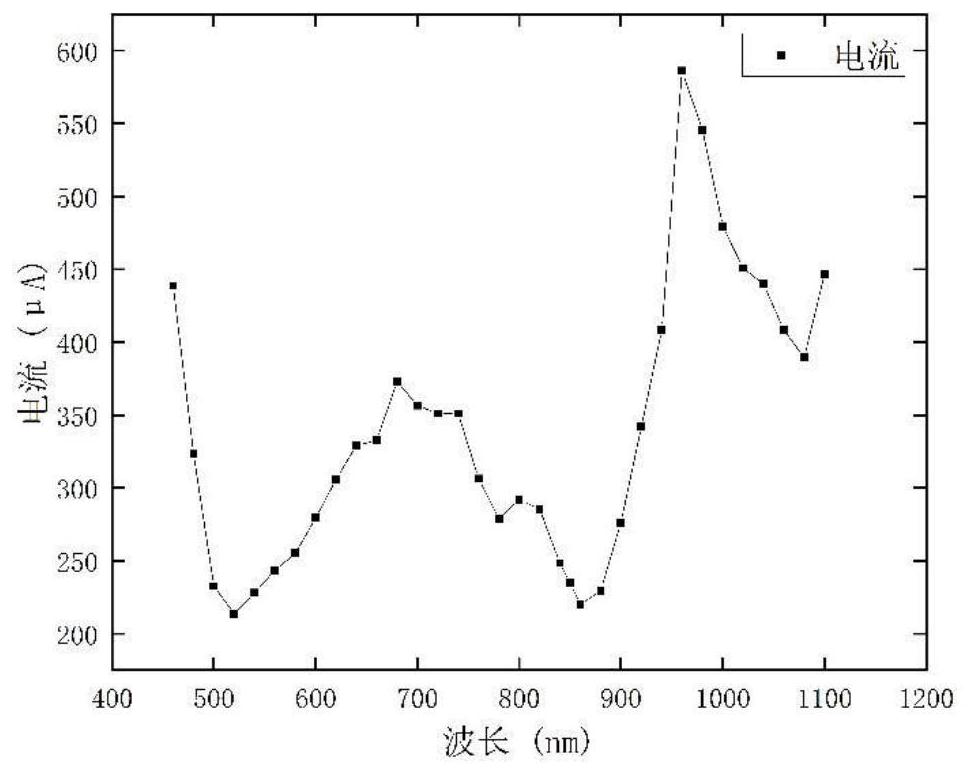

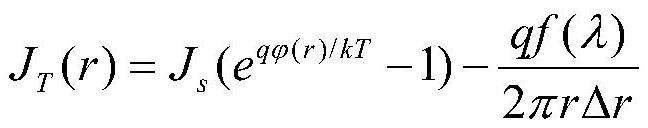

[0022] Depend on figure 1 As shown, the laser light source array is composed of a group of laser light sources with a certain wavelength. The wavelength of the laser light source is distributed in an arithmetic sequence, and the wavelength range is 400nm to 1100nm, and the wavelength tolerance is 20nm. The laser light source array is irradiated on the flexible photoelectric sensor to obtain the spectral response curve of the flexible photoelectric sensor, thereby obtaining the wavelength-current calibration result. Its theoretical formula is as follows:

[0023] The forward current is divided into two parts, one is the first part that can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com