Multi-stage dielectric barrier discharge plasma-catalysis cooperative treatment device for waste gas and wastewater

A dielectric barrier discharge and plasma technology, applied in the fields of magnetic field/electric field water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc. problems, to achieve the effect of reducing the existence of secondary pollutants, reducing secondary pollutants, and improving treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. A preferred embodiment is shown in the accompanying drawings, and the present invention can be implemented in various forms. Therefore, the scope of protection is not limited to the description of this example. The purpose of illustration is to better understand the implementation of the present invention.

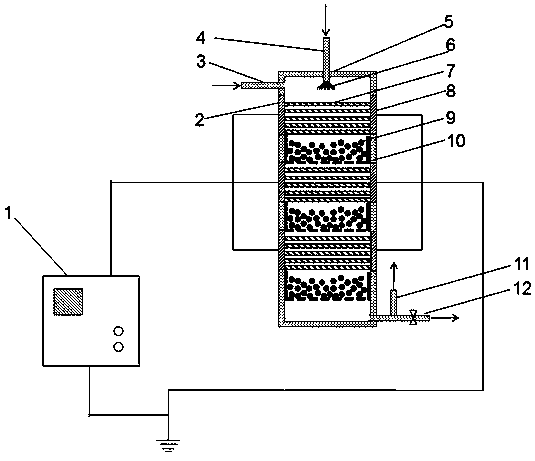

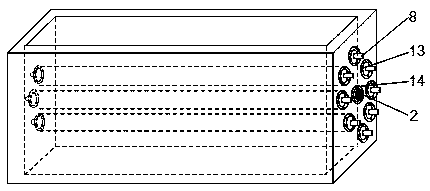

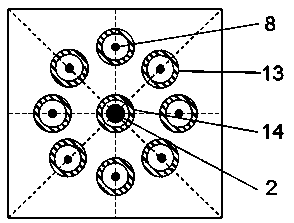

[0025] Such as Figure 1-4 As shown, the present invention is a multi-stage dielectric barrier discharge plasma synergistic catalytic treatment of waste gas and wastewater device, including a housing 5, in which plasma generators 7 are arranged alternately along the feed end to the discharge end The catalyst 9 or adsorbent supported by the perforated tray 10, the catalyst 9 or the adsorbent placed on the rear side of the plasma generator can effectively reduce the possibility of the existence of secondary pollutants, and each plasma generator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com