Boron/nitrogen double-doped porous carbon nanosheet and lithium-sulfur battery positive electrode material thereof

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, positive electrodes, etc., can solve the problems of volume expansion of electrode materials, improvement of sulfur cathode conductivity, etc., to achieve improved conductivity, excellent cycle performance, strong Lewis The effect of acid-base action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing boron / nitrogen double-doped porous carbon nanosheets and a positive electrode material for a lithium-sulfur battery, comprising the following steps:

[0035] Step 1, preparation of boron / nitrogen double-doped porous carbon nanosheets:

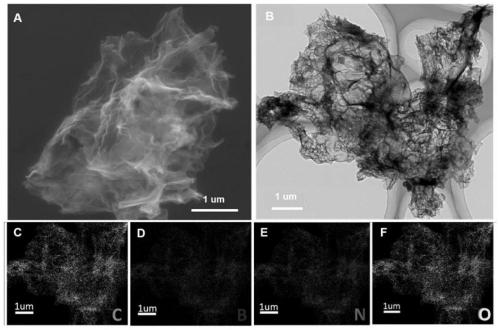

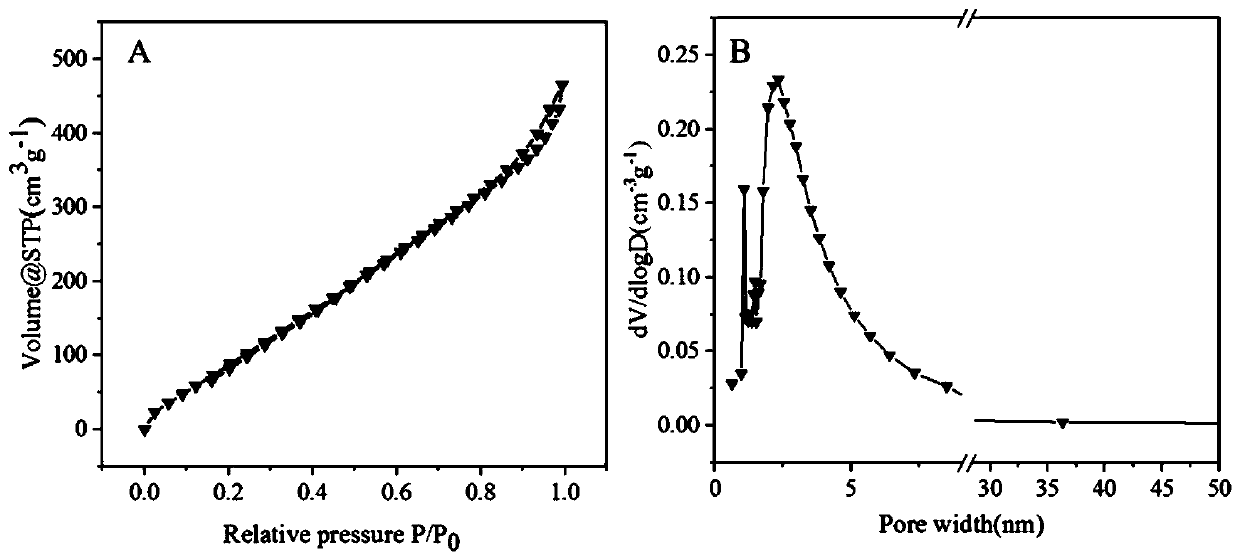

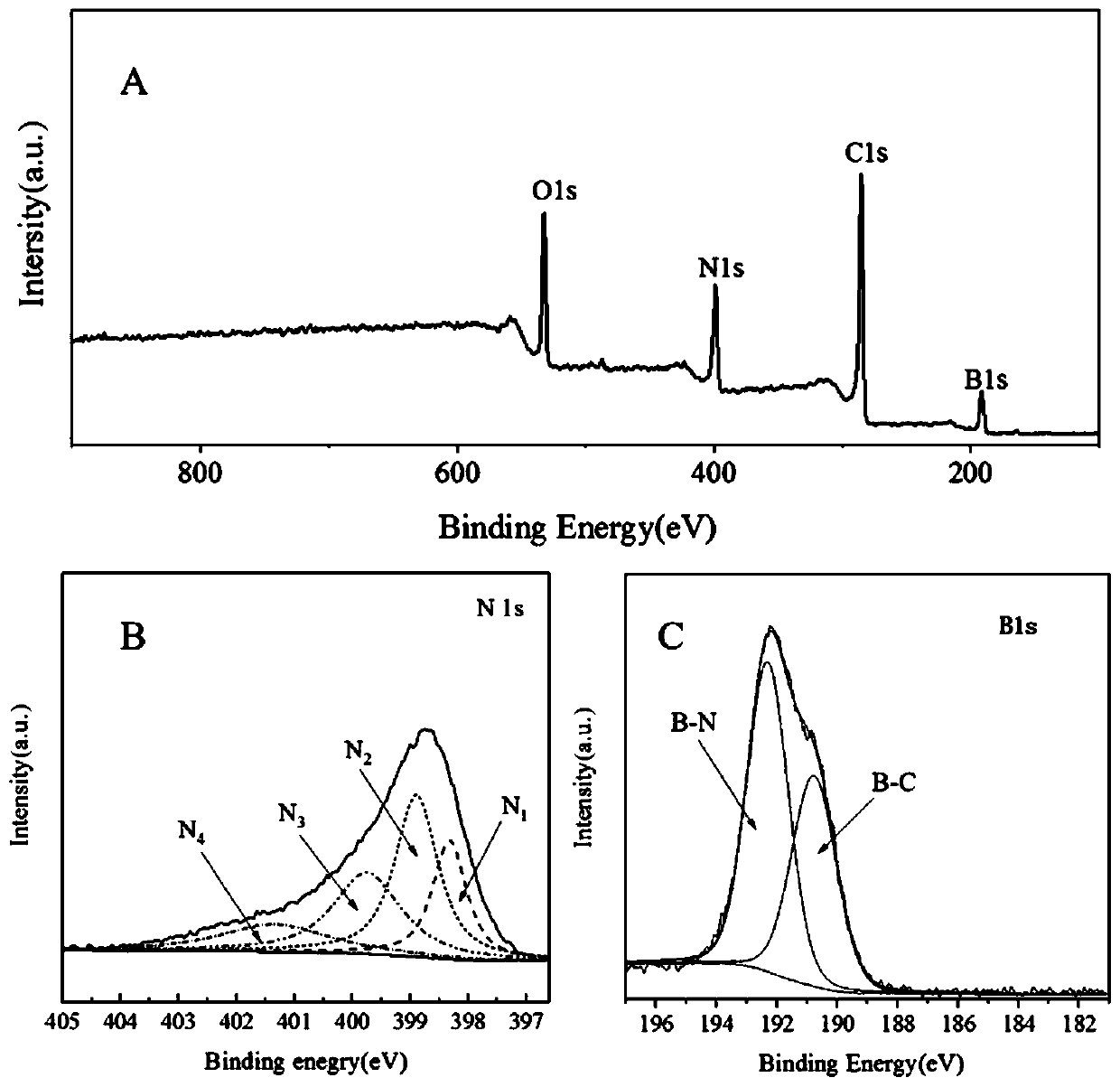

[0036] Weigh 80mmol (4.8g) of urea, 2.5mmol (0.1545g) of boric acid and 0.25mmol (0.5g) of polyethylene glycol-2000, add to 50mL of deionized water and stir evenly, evaporate and dry the resulting solution to obtain a white powder; Put the obtained white powder precursor into a tube furnace, heat up to 900°C at a rate of 5°C / min in an argon atmosphere, carbonize for 2 hours, and finally cool to room temperature to obtain boron / nitrogen double-doped porous carbon nanosheets;

[0037] Step 2, compounding the boron / nitrogen double-doped porous carbon nanosheets obtained in step 1 with simple sulfur:

[0038] Mix boron / nitrogen double-doped porous carbon nanosheets and sulfur simple substance at a mass ratio of 1:4, a...

Embodiment 2

[0040] A method for preparing boron / nitrogen double-doped porous carbon nanosheets and a positive electrode material for a lithium-sulfur battery, comprising the following steps:

[0041] Mix boron / nitrogen double-doped porous carbon nanosheets obtained in step 1 of Example 1 with sulfur element in a mass ratio of 1:3, grind to obtain a mixture of boron / nitrogen double-doped porous carbon nanosheets and sulfur, and place in a crucible Put the crucible containing the above mixture into a polytetrafluoroethylene reactor in an argon atmosphere and seal it; transfer the sealed reactor to an oven at 155°C and keep it warm for 12 hours; cool to room temperature to obtain lithium Sulfur battery cathode material (S / B-N-CNSs-2), the actual sulfur content measured by thermogravimetric test is ~76.1wt%.

Embodiment 3

[0043] A method for preparing boron / nitrogen double-doped porous carbon nanosheets and a positive electrode material for a lithium-sulfur battery, comprising the following steps:

[0044] Mix boron / nitrogen double-doped porous carbon nanosheets obtained in step 1 of Example 1 with sulfur element in a mass ratio of 1:2, grind to obtain a mixture of boron / nitrogen double-doped porous carbon nanosheets and sulfur, and place in a crucible Put the crucible containing the above mixture into a polytetrafluoroethylene reactor in an argon atmosphere and seal it; transfer the sealed reactor to an oven at 155°C and keep it warm for 12 hours; cool to room temperature to obtain lithium Sulfur battery cathode material (S / B-N-CNSs-3), the actual sulfur content measured by thermogravimetric test is ~67.0wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com