Method for removing perfluorooctanoic acid in water body by utilizing lignin-based carbon nanotubes

A technology based on carbon nanotubes and lignin, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of low efficiency limitation, low adsorption efficiency, secondary pollution of the environment, etc., and achieve large-scale application and industrialization Prospect, effect of high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

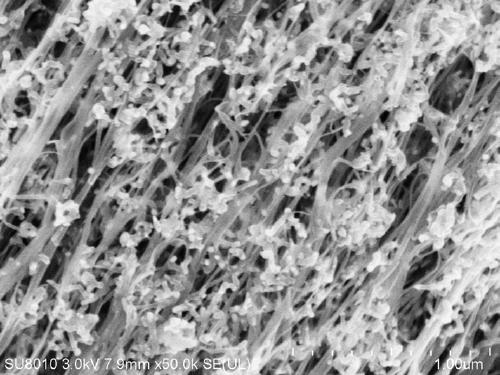

Image

Examples

Embodiment 1

[0028] Example 1 Method for removing perfluorooctanoic acid in water by using lignin-based carbon nanotubes

[0029] This embodiment includes the following steps:

[0030] (1) In parts by weight, fully mix 2 parts of guaiac lignin, 0.125 parts of dicyclopentadiene nickel, 0.125 parts of dicyclopentadiene iron, 0.25 parts of thiophene and 97.5 parts of methanol to obtain solution A ;;

[0031] (2) Under the protection of argon, deliver solution A at a rate of 0.1mL / min to the porous cracking tube 1 in the first high temperature zone with a temperature of 600°C, and crack guaiacol lignin into low molecular weight polyphenols Gas, this gas can form reflux at the end of porous cracking tube 1, the backflow release through porous cracking tube 1 forms stable gas and enters the second high temperature zone that temperature is 800 ℃ through the round hole 2 of porous cracking tube 1 end, and Further pyrolysis catalyzes growth to form continuous carbon nanotube aggregates, wherein t...

Embodiment 2

[0033] Example 2 The method of using lignin-based carbon nanotubes to remove perfluorooctanoic acid in water

[0034] This embodiment includes the following steps:

[0035] (1) In parts by weight, 1 part of syringyl lignin, 0.05 part of dicyclopentadiene nickel, 0.20 part of dicyclopentadiene iron, 0.25 part of thiophene and 98.5 parts of methanol were thoroughly mixed to obtain solution A;

[0036] (2) Under the protection of nitrogen, deliver solution A to the porous cracking tube 1 in the first high temperature zone at a rate of 0.05mL / min. The temperature in the first high temperature zone is 660°C, and syringyl lignin is cracked into low molecular weight and light Polyphenol gas, after the gas is released through the reflux of the porous cracking tube 1, enters the second high-temperature zone with a temperature of 900°C through the round hole 2, and further cracks and catalyzes the growth in the second high-temperature zone to form continuous particles with a diameter of...

Embodiment 3

[0038] Example 3 Method for removing perfluorooctanoic acid in water by using lignin-based carbon nanotubes

[0039] This embodiment includes the following steps:

[0040] (1) In parts by weight, fully mix 5 parts of p-hydroxyphenyl lignin, 0.005 parts of dicyclopentadiene nickel, 0.005 parts of dicyclopentadiene iron, 0.25 parts of thiophene and 94.74 parts of methanol to obtain a solution A;

[0041] (2) Under nitrogen protection, deliver solution A to the porous cracking tube 1 in the first high temperature zone at a rate of 0.08mL / min. The temperature in the first high temperature zone is 800°C, and p-hydroxyphenyl lignin is cracked into low molecular weight Light polyphenol gas, the gas is released through the reflux of the porous cracking tube 1, enters the second high temperature zone with a temperature of 1000°C through the round hole 2, and further cracks and catalyzes the growth in the second high temperature zone to form a continuous aggregates of carbon nanotubes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com