High-fluidity black masterbatch for PA engineering plastics and preparation method thereof

A high-flow technology for engineering plastics, applied in the field of high-flow black masterbatch for PA engineering plastics and its preparation, can solve the problems of difficulty in meeting the processability and surface requirements of high-filled nylon engineering plastics, and achieves improved processing fluidity and improved dispersion. effect, the effect of improving blackness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

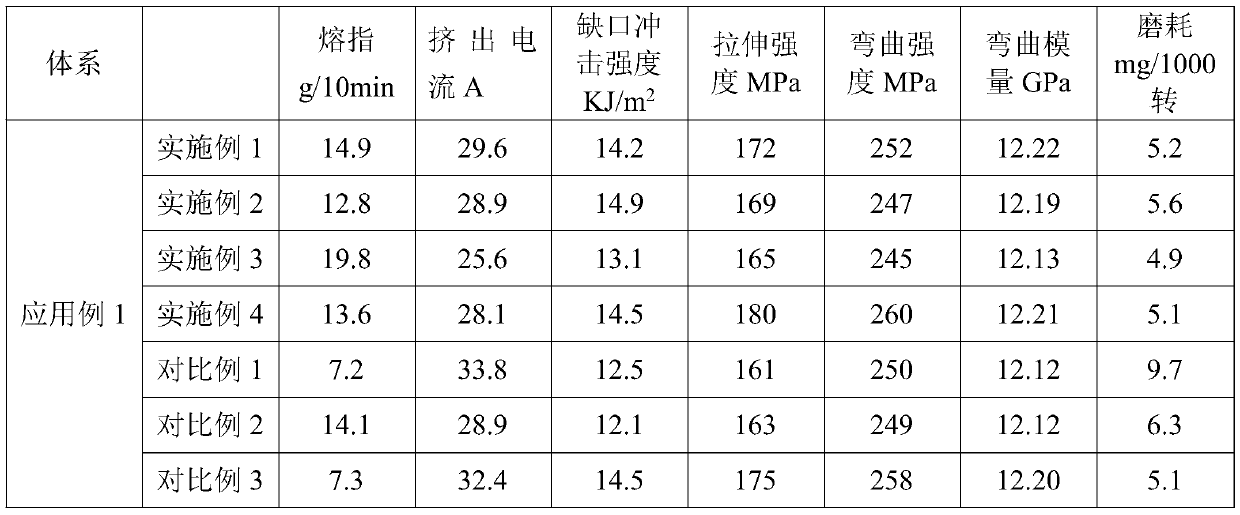

Examples

Embodiment 1

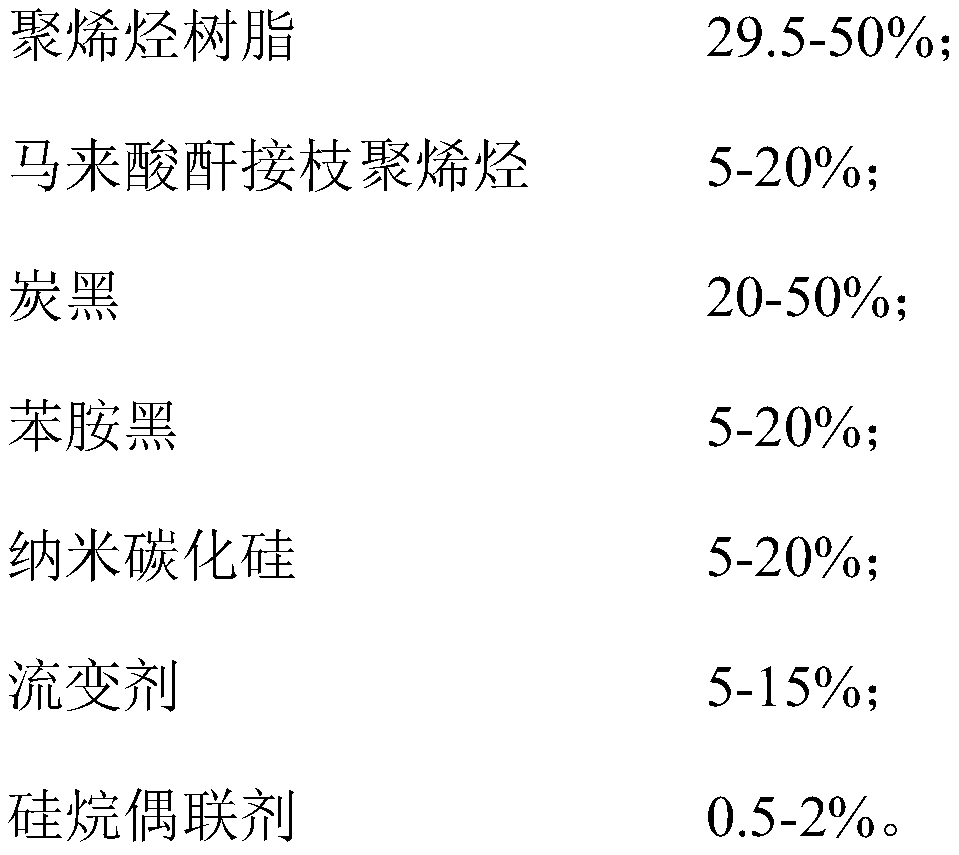

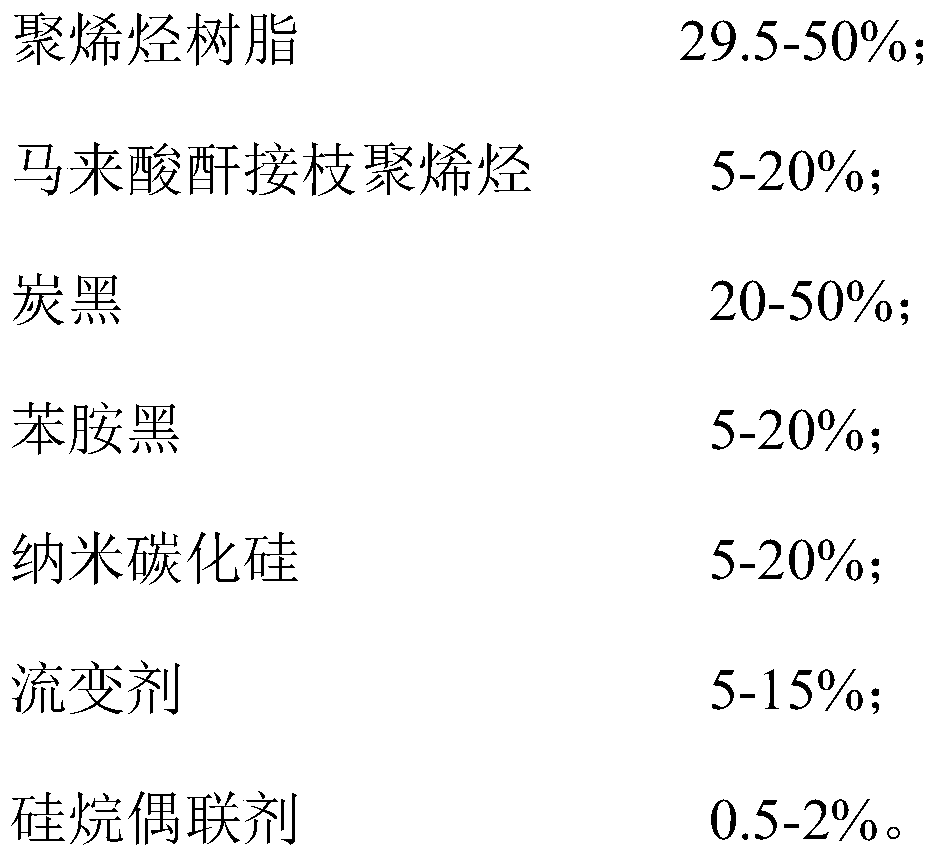

[0025] A high-flow black masterbatch for PA engineering plastics, by weight percentage, includes the following components:

[0026] LDPE MG70 33%;

[0027] PE-g-MAH 15%;

[0028] High Pigment Carbon Black 25%;

[0029] Oil soluble black 7 10%;

[0030] Nano silicon carbide 10%;

[0031] Tetradecanedioic acid 5%;

[0032] Silane coupling agent KH550 2%;

[0033] Its preparation method comprises the following steps:

[0034] (1) Mix high-pigment carbon black, oil-soluble black 7, and nano-silicon carbide with xylene, add silane coupling agent KH550, stir and mix, heat to 80°C, react for 4 hours, and rotate to evaporate at 75°C after the reaction Concentrate, then dry, and dry the obtained solid at 105°C for grinding to obtain modified high-pigment carbon black, modified oil-soluble black 7, and modified nano-silicon carbide;

[0035] (2) The above-mentioned modified high-pigment carbon black, modified oil-soluble black 7, and modified nano-silicon carbide are mixed unifor...

Embodiment 2

[0037] A high-flow black masterbatch for PA engineering plastics, by weight percentage, comprising the following components:

[0038] POE 8200 33%;

[0039] POE-g-MAH 15%;

[0040] High Pigment Carbon Black 25%;

[0041] Oil soluble black 7 10%;

[0042] Nano silicon carbide 10%;

[0043] Tetradecanedioic acid 5%;

[0044] Silane coupling agent KH560 2%;

[0045] Its preparation method comprises the following steps:

[0046] (1) Mix high-pigment carbon black, oil-soluble black 7, and nano-silicon carbide with xylene respectively, add silane coupling agent KH560, stir and mix, heat to 80°C, react for 4 hours, and rotate to evaporate at 75°C after the reaction Concentrate, then dry, and dry the obtained solid at 105°C for grinding to obtain modified high-pigment carbon black, modified oil-soluble black 7, and modified nano-silicon carbide;

[0047] (2) the above-mentioned modified high-pigment carbon black, modified oil-soluble black 7, and modified nano-silicon carbide a...

Embodiment 3

[0049] A high-flow black masterbatch for PA engineering plastics, by weight percentage, comprising the following components:

[0050] LDPE MG70 30%;

[0051] PE-g-MAH 15%;

[0052] High Pigment Carbon Black 25%;

[0053] Oil soluble black 7 10%;

[0054] Nano silicon carbide 10%;

[0055] Tetradecanedioic acid 8%;

[0056] Silane coupling agent KH550 2%;

[0057] Its preparation method comprises the following steps:

[0058] (1) Mix high-pigment carbon black, oil-soluble black 7, and nano-silicon carbide with xylene, add silane coupling agent KH550, stir and mix, heat to 80°C, react for 4 hours, and rotate to evaporate at 75°C after the reaction Concentrate, then dry, and dry the obtained solid at 105°C for grinding to obtain modified high-pigment carbon black, modified oil-soluble black 7, and modified nano-silicon carbide;

[0059] (2) The above-mentioned modified high-pigment carbon black, modified oil-soluble black 7, and modified nano-silicon carbide are mixed unifor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com